Page 12

Installer’s Guide

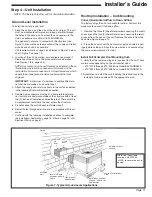

Placing the Unit on the Mounting Curb

1. The unit is designed with a perimeter drip lip that is lower than

the unit base pan, see Figure 10, inset A, on page 14.

2. Position the unit drip lip down over and in contact with the outside

corner of the curb, as illustrated in Figure 10, inset A, on page

14. Continue to lower the unit on top of the curb, with the unit

drip lip astraddle, and in contact with, both the end and side rail

of the curb. The unit should now rest on top of the curb. Use the

extreme mounting kit, BAYEXMK001A, to add additional hold

down strength to the mounting.

NOTE: The ductwork is installed as part of the curb installa-

tion. Do not attach ductwork to the unit and lower the unit with

ductwork onto the curb.

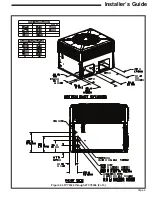

Figure 8. Converting Horizontal to Down Airflow

1. Before preparing the unit for lifting, check the unit dimension

drawings for center of gravity for lifting safety (Figures 1 to 6,

page 4-9

).

Because of placement of internal components, the

unit’s weight may be unevenly distributed. Approximate unit

weights are also provided in the unit drawings.

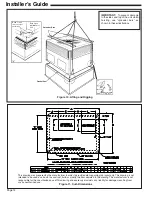

NOTE: Unit rigging and hoisting requires accessory kit BAY-

LIFT002A

.

It includes a kit of four (4) lifting lugs. See Figure 10

inset B, on page 14.

2. Insert the four lifting lugs in the openings provided in the drip lip

on each end of the unit. See Figure 10 inset B on page 14. A

tap or jerk to the lug will overcome the interference that arises

due to the dimple on the lug.

3. When hoisting the unit, be sure that a proper method of rigging

is used. Use straps or slings and spreader bars for protection

during lifting. Always test-lift the unit to determine the exact unit

balance and stability before hoisting it to the installation location.

4. When the curb and air ducts have been properly installed, the

unit is ready to be hoisted to the roof and set in position.

IMPORTANT:

To prevent damage to the sides and top of the

unit when hoisting, use “spreader bars” as shown on page 14.

IMPORTANT:

The unit must be lowered into position. The P.V.C.

rubber tape on the curb flange permits the unit to be repositioned

if required without destroying the P.V.C. rubber seals affixed to

the mounting curb.

Lifting and Rigging

IMPORTANT:

Do not lift the unit without test lifting for balance

and rigging. Do not lift the unit in windy conditions or above

personnel. Do not lift the unit by attaching clevis, hooks, pins,

or bolts to the unit casing, casing hardware, corner lugs, angles,

tabs, or flanges. Failure to observe these warnings may result

in equipment damage.

Summary of Contents for 4TCY4024

Page 5: ...Page 5 Installer s Guide Figure 2 4TCY4024 through 4TCY4036 2 of 3...

Page 6: ...Page 6 Installer s Guide Figure 3 4TCY4024 through 4TCY4036 3 of 3...

Page 8: ...Page 8 Installer s Guide Figure 5 4TCY4042 through 4TCY4060 2 of 3...

Page 9: ...Page 9 Installer s Guide Figure 6 4TCY4042 through 4TCY4060 3 of 3...

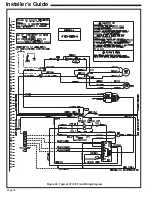

Page 18: ...Page 18 Installer s Guide Figure 20 Typical 4TCY4 Field Wiring Diagram...

Page 22: ...Page 22 Installer s Guide Notes...