Page 10

3.2 Mounting the Enclosure

The

mini

CHEM

-DO

2

can be wall-mounted with 3 screws. Two mounting points

are located underneath the terminal cover, and are positioned so that they do not

affect the waterproofing of the enclosure. The third mounting point is centrally

located near the top of the rear of the enclosure, and has been designed to hook

over a screw-head. The dimensions for the mounting screw centres are provided on

the rear of the enclosure. The last page of this manual may be photocopied or

removed for use as a drilling template.

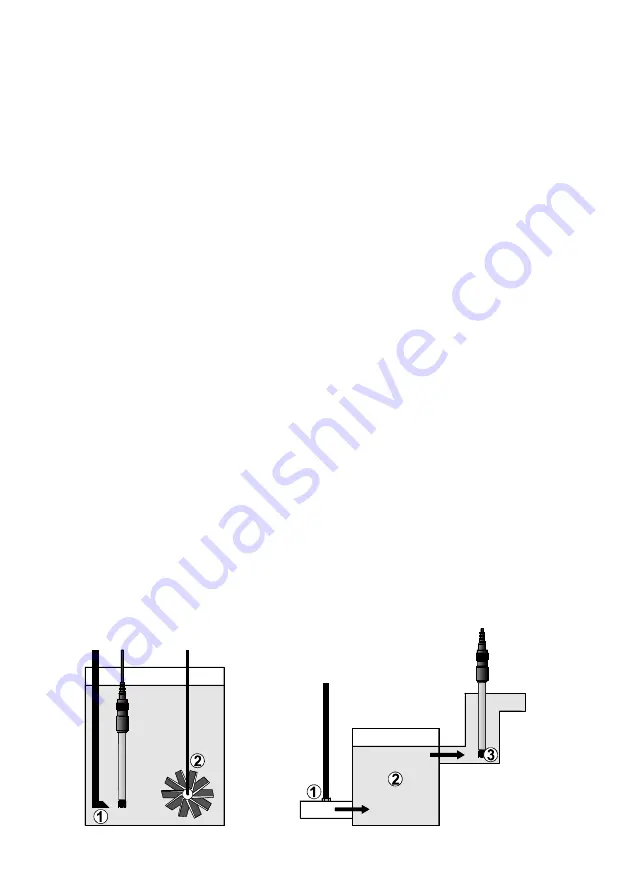

3.3 Mounting the Sensors

Mounting the sensor is a very important aspect of the installation, and is often done

incorrectly. In automatic control situations, the sensor should always be mounted

as close as possible to the injection point. This will cause the sensor to detect the

added oxygen or chemicals immediately, and shut the addition off until mixing has

taken place. For in-line mounting, it is important that oxygen or chemicals are

injected upstream. Additionally, the line must be run through a mixing chamber,

such as a large drum, to ensure that the injected oxygen or chemical has mixed in

properly by the time the solution flows past the sensor. There must always be

adequate flow of fresh sample past the sensor, for accurate monitoring. The

diagrams below show typical mounting arrangements for “dip” mounting and in-

line mounting.

Dip Mounting

1. Injection point close to sensor.

2. Continuous stirring.

In-line Mounting

1. Injection point upstream from and

close to sensor.

2. Mixing container after injection and

before sensor.

3. DO

2

sensor mounted as close to

vertical as practical, through a

suitable gland fitting.