18 PLANNED MAINTENANCE

en‐83

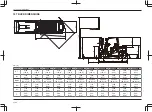

Inspection Period

(Based on operating hours or months, whichever is

soonest.)

Every

6

weeks

Every

3

months

Every

6

months

Every

12

months

Item

Every

250

hours

Every

500

hours

Every

1000

hours

Every

2000

hours

Hydraulic piping

Oil leak

I

*

*

Deformation and damage

I

*

*

Loose joint

T

*

*

ELECTRICAL SYSTEM

Ignition system

State of spark plug (carbon, soot)

I

*

*

*

Starter motor

Pinion gear meshing status

I

*

*

Battery

Battery fluid level

I

*

*

Battery fluid specific gravity

M

*

Electrical wiring

Damage of wiring harness

I

*

*

Fuses

I

*

*

Preheater

Opencircuit in glow plug

I

*

LPG DEVICE

LPG Device (Op

tion)

Gas leak from fuel lines and fittings

I

*

*

*

Damage of fuel lines and fittings

I

*

*

*

Tar removal from regulator

C

*

*

*

Regulator adjustment status

I

*

*

*

Regulator function

I

*

*

Mixer

I

*

*

Filter clogging

C

*

*

Service valve function

I

*

*

Leaks, damage, and cracks of the

tank

I

*

*

*

Loose or damaged tank bracket

I

*

*

*

Damage to electrical wiring, loose

terminals

I

*

*

*

Rotation of liquid drain valve

I

*

*

*

Gas leak from the regulator body

I

*

*

*

SAFETY DEVICES AND OTHERS

Overhead guard

Cracks at welded portion

I

*

*

Deformation and damage

I

*

*

Backrest

Loosening of mounting

T

*

*

Deformation, crack and damage

I

*

*

Inspection Period

(Based on operating hours or months, whichever is

soonest.)

Every

6

weeks

Every

3

months

Every

6

months

Every

12

months

Item

Every

250

hours

Every

500

hours

Every

1000

hours

Every

2000

hours

Lighting system

Function and mounting condition

I

*

*

Horn

Function and mounting condition

I

*

*

Grease horn contact ring and horn

contact spring

L

Instruments

Functions

I

*

*

Backup

buzzer

(Option)

Function and mounting condition

I

*

*

Rearview mirror

(Option)

Dirt, damage

I

*

*

Rear reflection status

I

*

*

Seat

Loosening and damage of mounting

I

*

*

Seat damage and function

I

*

*

Seat belt

Mounting looseness

I

*

*

Webbing

damage

(cut,

frayed

straps, loose stitching)

I

*

*

Plate damage

I

*

*

Buckle and retractor damage

I

*

*

Function (retract and locks)

I

*

*

Body

Damage and cracks of frame, cross

members, etc.

I

Bolt looseness

T

Frame bolt

I

SAS

Functions

I

*

*

Loosening and damage at sensor

mounting

I

*

*

Damage, deformation, oil leakage

and loosening of the mounting of

functional parts

I

*

*

Loosening and damage of wire har

nesses

I

*

*

Lock cylinder accumulator perform

ance

I

Rusting and corrosion of load sensor

I

OPS

Functions

I*

1

I

*

*

18

Summary of Contents for 40--8FD35N

Page 92: ...19 TRUCK DIMENSIONS en 93 19...