30-EN

29-EN

– 15 –

Vacuum pump

As shown in the

fi

gure, connect the charge hose after

the manifold valve is closed completely.

↓

Attach the connecting port of the charge hose with a

projection to push the valve core (setting pin) to the

charge port of the set.

↓

Open Handle Low fully.

↓

Turn ON the vacuum pump. (*1)

↓

Loosen the

fl

are nut of the packed valve (Gas side)

a little to check that the air passes through. (*2)

↓

Retighten the

fl

are nut.

↓

Execute vacuuming until the compound pressure gauge

indicates –101 kPa (–76 cmHg). (*1)

↓

Close Handle Low completely.

↓

Turn OFF the vacuum pump.

↓

Leave the vacuum pump as it is for 1 or 2 minutes, and

check that the indicator of the compound pressure gauge

does not return.

↓

Open the valve stem or valve handle fully.

(First, at liquid side, then gas side)

↓

Disconnect the charge hose from the charge port.

↓

Tighten the valve and caps of the charge port securely.

*1: Use the vacuum pump, vacuum pump adapter, and gauge

manifold correctly referring to the manuals supplied with

each tool before using them.

Check that the vacuum pump oil is

fi

lled up to the speci

fi

ed

line of the oil gauge.

*2: When air is not charged, check again whether the

connecting port of the discharge hose, which has a

projection to push the valve core, is

fi

rmly connected to the

charge port.

6

Air purging

Airtight test

After completing the refrigerant piping work, perform an airtight test. Connect a nitrogen gas cylinder and

pressurize the pipes with nitrogen gas as follows to conduct the airtight test.

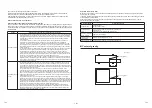

V

L

V

H

Charge port

Low pressure gauge

High pressure gauge

Gauge manifold

Pressure reducing valve

Nitrogen gas

CAUTION

Never use oxygen,

fl

ammable gas,

or noxious gas for the airtight test.

Gas leak check

Step 1....Pressurize to

0.5 MPa

(5 kg/cm²G) for 5 minutes or longer.

Major leaks can be discovered.

Step 2....Pressurize to

1.5 MPa

(15 kg/cm²G) for 5 minutes or longer.

Step 3....Pressurize to

4.15 MPa

(42 kg/cm²G) for 24 hours. ................ Micro leaks can be discovered.

(However, note that when the ambient temperature differs during pressurization and after 24 hours, the pressure

will change by approximately 0.01 MPa (0.1 kg/cm²G) per 1°C, so this should be compensated.)

If the pressure drops in steps 1 through 3, check the connections for leakage.

Check for leaks with foaming liquid, etc., take steps to

fi

x the leaks such as brazing the pipes again and

tightening the

fl

are nuts, and then perform the airtight test again.

* After the airtight test is completed, evacuate the nitrogen gas.

Air purge

With respect to the preservation of the terrestrial

environment, adopt “Vacuum pump” to purge air

(Evacuate air in the connecting pipes) when installing

the unit.

y

Do not discharge the refrigerant gas to the

atmosphere to preserve the terrestrial environment.

y

Use a vacuum pump to discharge the air (nitrogen,

etc.) that remains in the set. If air remains, the

capacity may decrease.

For the vacuum pump, be sure to use one with a

back

fl

ow preventer so that the oil in the pump does not

back

fl

ow into the pipe of the air conditioner when the

pump stops.

(If oil in the vacuum pump is put in an air conditioner

including R32, it may cause trouble with the

refrigeration cycle.)

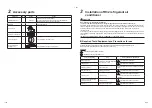

Compound pressure gauge

Pressure gauge

Gauge manifold valve

Handle High

(Keep fully closed)

Charge hose

(For R32/R410A)

Vacuum pump adapter

for counter

fl

ow

prevention

(For R32/R410A)

Vacuum

pump

Charge port

(Valve core

(Setting pin))

Charge hose

(For R32/R410A)

Handle Low

–101 kPa

(–76 cmHg)

Packed valve at gas side

Pump down process

1. Turn off the Air Conditioner system.

2. Connect the charge hose from the manifold valve

to the service port of the packed valve at gas side.

3. Turn on the Air Conditioner system in cooling

operation more than 10 minutes.

4. Check the operating pressure of the system should

be normal value.

(Ref. with product speci

fi

cation)

5. Release the valve rod cap of both service valves.

6. Use the Hexagon wrench to turning the valve rod

of Liquid side fully close.

(*Make sure no entering air into the system)

7. Continue operate Air Conditioner system until and

the gauge of manifold dropped into the range of

0.5 - 0 kgf/cm²

8. Use the Hexagon wrench to turning the valve rod

of Gas side fully close.

And turn off the Air Conditioner system immediately

thereafter.

9. Remove the gauge manifold from the service port

of the packed valve.

10. Securely tighten the valve rod cap to the both

service valves.

CAUTION

Should be check the compressor operating condition

while pumping down process. It must not any

abnormal sound, more vibration. It is abnormal

condition appears and must turn off the

Air Conditioner immediately.