26-EN

25-EN

– 13 –

Flaring

1. Cut the pipe with a pipe cutter.

Be sure to remove burrs that may cause a gas leak.

2. Insert a

fl

are nut into the pipe, and then

fl

are the

pipe.

Use

the

fl

are nuts supplied with the air conditioner

or those for R32.

Insert

a

fl

are nut into the pipe, and

fl

are the pipe.

Use

the

fl

are nuts supplied with the air conditioner

or

fl

are nuts for R32 or R410A.

However, the conventional tools can be used by

adjusting the projection margin of the copper pipe.

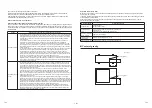

Projection margin in

fl

aring: B (Unit: mm)

B

RIGID (Clutch type)

Outer dia. of

copper pipe

Tool used

Conventional

tool used

9.5

0 to 0.5

1.0 to 1.5

15.9

Flaring dia. size: A (Unit: mm)

A

Outer dia. of copper pipe

A +0

–0.4

9.5

13.2

15.9

19.7

CAUTION

y

Do not scratch the inner surface of the

fl

ared part

when removing burrs.

y

Flare processing under the condition of scratches

on the inner surface of

fl

are processing part will

cause refrigerant gas leak.

y

Check that the

fl

ared part is not scratched,

deformed, stepped, or

fl

attened, and that there

are no chips adhered or other problems, after

fl

are

processing.

y

Do not apply refrigerating machine oil to the

fl

are

surface.

5

Refrigerant piping

Supplied protective bush

Supplied passage hole

guard material

* Attach the guard material

securely so that it does

not come loose.

Optional installation parts

(Locally procured)

Parts name

Q’ty

A

Refrigerant piping

Liquid side: Ø9.5 mm

Gas side: Ø15.9 mm

One each

B

Pipe insulating material

(polyethylene foam, 10 mm thick)

1

C

Putty, PVC tape

One each

Refrigerant piping connection

CAUTION

IMPORTANT 4 POINTS FOR PIPING WORK

1. Reusable mechanical connectors and

fl

ared

joints are not allowed indoors. When mechanical

connectors are reused indoors, sealing parts shall

be renewed.

When

fl

ared joints are reused indoors, the

fl

are

part shall be refabricated.

2. Tight connection (between pipes and unit)

3. Evacuate the air in the connecting pipes by using

VACUUM PUMP.

4. Check the gas leakage. (Connected points)

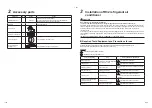

Piping connection

Liquid side

Outer diameter

Thickness

Ø9.5 mm

0.8 mm

Gas side

Outer diameter

Thickness

Ø15.9 mm

1.0 mm

Knockout of pipe cover

Knockout procedure

Rear direction

Side direction

Down direction

Front direction

Pipe cover

y

The indoor / outdoor connecting pipes can be

connected in 4 directions.

Take off the knockout part of the pipe cover through

which pipes or wires will pass through the base

plate.

y

Detach the pipe cover and tap on the knockout

section a few times with the shank of a screwdriver.

A knockout hole can easily be punched.

y

After punching out the knockout hole, remove burrs

from the hole and then install the supplied protective

bush and guard material around the passage hole to

protect wires and pipes.

Be sure to attach the pipe covers after pipes have

been connected. Cut the slits under the pipe covers

to facilitate the installation.

After connecting the pipes, be sure to mount the pipe

cover. The pipe cover is easily mounted by cutting off

the slit at the lower part of the pipe cover.

* Be sure to wear heavy work gloves while working.

Refrigerant Piping

1. Use the following items for the refrigerant

piping.

Material : Seamless phosphorous deoxidized

copper pipe.

Ø9.52 Wall thickness 0.8 mm or more

Ø15.88 Wall thickness 1.0 mm or more

Do not use any copper pipes with a wall

thickness less than these thicknesses.

Removing service panel

y

Remove the screws at 2 locations and slide the

service panel down. Next, detach the right-side

claws followed by left-side claws to remove the

service panel.

When doing this, pulling the service panel towards

the front could damage the claws.

When attaching the service panel, attach the left

claws followed by the right claws and lift the service

panel upwards and secure it with screws in the 2

locations.

Service panel

Right-side plate

Right-side

claws

Left-side

claws

(1)

(2)

(3)