– 16 –

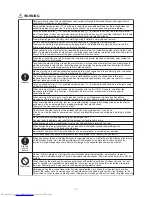

4. Tools

Tools exclusive for R410A (The following tools for R410A are required.)

Note 1

When flaring is carried out for R410A or R32 using the conventional flare tools, adjustment of

projection margin is necessary. For this adjustment, a copper pipe gauge, etc. are necessary.

Note 2

When saturation temperature is described, the gauge manifold differs for R410A and R32.

If saturation temperature reading is required, special tools exclusive for R32 are required.

Note 3

Since R32 has a slight possibility of burning, be sure to use the tools corresponding to R32.

Note 4

Like R410, a Vacuum pump adapter needs installing to prevent a Vacuum pump oil (mineral oil) from

flowing backward into the Charge hose. Mixing of the Vacuum pump oil into R32 refrigerant may cause

a trouble such as generation of sludge, clogging of capillary, etc.

Note 5

Be sure to use those tools after confirming they correspond to each refrigerant.

Note 6

For a refrigerant cylinder exclusive for R32, the paint color (or label color) of the cylinder is set to the

specified color (light blue) together with the indication of the refrigerant name.

Note 7

Although the container specification is the same as R410A, use a recovering container exclusive for

R32 to avoid mixing with other refrigerants.

Note 8

Be careful for miss-charging of the refrigerant during work. Miss-charging of the refrigerant type may

cause not only damage of the equipments but also a fire etc.

: R410A tools available

: Partly unavailable,

: R410A tools unavailable

No.

Installation/service tools

Tools / Equipment

specification

1 Flare tool

Clutch type

Pipe flaring

Use

Applicability to R32 air

conditioner or not

Applicability to R22 air

conditioner or not

5 Charge hose

High-voltage

3 Torque wrench

—

Tightening of

flare nut

6 Vacuum pump

—

Vacuum

drying

Note 3

1/2"-20UNF(5/16" Flare)

Connection diameter

1/4"

7 Vacuum pump adapter

—

Vacuum

drying

Note 4

1/2"-20UNF(5/16" Flare)

Connection diameter

1/4"

8 Electronic balance for

refrigerant charging

For 10 kg or

20 kg cylinder

Refrigerant

charge

9 Leakage detector

—

Gas leakage

check

Note 5

Note 5

10 Refrigerant cylinder

—

Refrigerant

charge

Note 6

11 Refrigerant recovery

cylinder

Exclusive for

R32

Refrigerant

recovery container

Note 7

12 Refrigerant recovery

device

—

Refrigerant

recovery device

Note 8

Connection diameter

1/4"

4 Gauge manifold

Port size

1/2"-20UNF

(5/16" Flare)

Evacuating,

refrigerant

charge, run

check, etc.

Note 2

2

Copper pipe gauge for

adjusting projection

margin

—

—

Flaring by

conventional

flare tool

In addition to the above exclusive tools, the following equipments are necessary as the general tools.

General tool

s

1)

Pipe

cutter

6)

S

panner or Monkey wrench

2)

Reamer

7)

Hole

core

drill

3)

Pipe

bender

8)

Tape

measure

4)

Level

vial

9)

Metal

saw

5)

S

crewdriver (+, –)

Also prepare the following equipments for other installation method and run check.

1) Clamp meter

3) Insulation resistance tester (Megger)

2)

Thermometer

4)

Electroscope