– 58 –

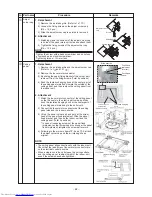

(3) Check procedures

Table 10-6-1

s

e

s

u

a

C

s

t

n

i

o

p

k

c

e

h

C

e

r

u

d

e

c

o

r

P

.

o

N

1

T

u

rn off the power

su

pply

b

re

a

ker

a

nd remove the P.C.

b

o

a

rd

ass

em

b

ly from electronic p

a

rt

s

bas

e. Remove the connecting

c

ab

le

s

from the termin

a

l

b

lock.

Check whether or not the f

us

e (F01)

i

s

b

lown.

Imp

u

l

s

e volt

a

ge w

as

a

pplied or the

indoor f

a

n motor

s

hort-circ

u

ited.

2

Remove the connector of the motor

a

nd t

u

rn on the power

su

pply

b

re

a

ker. If OPERATION indic

a

tor

fl

as

he

s

(once per

s

econd), it i

s

not

nece

ssa

ry to check

s

tep

s

(1 to

3

) in

the right next col

u

mn.

Check power

su

pply volt

a

ge :

1. Between No. 1

a

nd No.

3

of CN67

(AC 220–240V)

2. Between

a

nd

of

CN0

8

(DC

3

10–

3

40V)

3

. Between 12V

a

nd GND

4. Between 5V

a

nd GND

1. The termin

a

l

b

lock or the cro

ss

over

c

ab

le i

s

connected wrongly.

2. The c

a

p

a

citor (C01) V

a

ri

s

tor (R01),

line filter (L01), re

s

i

s

tor (R0

3

,R04), or

the diode (DB01) i

s

defective.

3

. T01 i

s

defective.

4. IC01,IC02

a

nd T01

a

re defective.

3

P

us

h [

]

bu

tton once to

s

t

a

rt the

u

nit. (Do not

s

et the mode to On-

Timer oper

a

tion.)

Check power

su

pply volt

a

ge :

1. Between No.1

a

nd No.

3

of CN67

(DC 15–60V)

IC0

8

a

nd IC0

9

a

re defective.

4

Shorten the re

s

t

a

rt del

a

y timer

a

nd

s

t

a

rt

u

nit.

Check whether or not

a

ll indic

a

tor

s

(OPERATION, TIMER, PRE. DEF, Hi

POWER)

a

re lit for

3

s

econd

s

a

nd

they ret

u

rn to norm

a

l

3

s

econd

s

l

a

ter.

The indic

a

tor

s

a

re defective or the

ho

us

ing

ass

em

b

ly (CN214) i

s

defective.

5

P

us

h [

]

bu

tton once to

s

t

a

rt the

u

nit.

• Shorten the re

s

t

a

rt del

a

y timer.

• Set the oper

a

tion mode to COOL.

• Set the f

a

n

s

peed level to AUTO.

• Set the pre

s

et temper

a

t

u

re m

u

ch

lower th

a

n the room temper

a

t

u

re.

(The

u

nit (compre

ss

or) oper

a

te

s

contin

u

o

us

ly in the

ab

ove

condition.)

1. Check whether or not the

compre

ss

or oper

a

te

s

.

2. Check whether or not the

OPERATION indic

a

tor fl

as

he

s

.

1. The temper

a

t

u

re of the indoor he

a

t

exch

a

nger i

s

extremely low.

2. The connection of the he

a

t exch

a

nger

s

en

s

or i

s

loo

s

e.

(The connector i

s

di

s

connected.)

(CN101,CN102)

3

. The he

a

t exch

a

nger

s

en

s

or

a

nd the

P.C.

b

o

a

rd

a

re defective.

(Refer to T

ab

le 10-4-1.)

4. The m

a

in P.C.

b

o

a

rd i

s

defective.

6

Connect the motor connector to the

motor

a

nd t

u

rn on the power

su

pply.

St

a

rt the

u

nit the following

condition.

• Set the f

a

n

s

peed level to HIGH.

(The

u

nit (compre

ss

or) oper

a

te

s

contin

u

o

us

ly in the

ab

ove

condition in No. 5.)

1. Check it i

s

impo

ss

i

b

le to detect the

volt

a

ge (DC15V)

b

etween No.4

a

nd No.5 of the motor termin

a

l

s

.

2. The motor doe

s

not oper

a

te or the

f

a

n motor doe

s

not rot

a

te with high

s

peed.

(B

u

t it i

s

po

ss

i

b

le to receive the

s

ign

a

l from the remote controller.)

3

. The motor rot

a

te

s

bu

t vi

b

r

a

te

s

s

trongly.

1. The indoor f

a

n motor i

s

defective.

(Protected oper

a

tion of P.C.

b

o

a

rd.)

2. The P.C.

b

o

a

rd i

s

defective.

3

. The connection of the motor

connector i

s

loo

s

e.