– 77 –

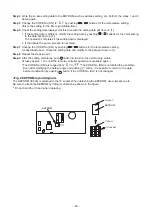

Check code

Location

of

detection

De

s

cription

S

y

s

tem

s

tatu

s

Problem detection

condition(

s

)

Check item

s

(location

s

)

• Check flo

a

t

s

witch connector.

• Check oper

a

tion of dr

a

in

p

u

mp.

• Check dr

a

in p

u

mp circ

u

it.

• Check dr

a

in pipe for clogging.

• Check for defect in indoor

P.C.

b

o

a

rd.

Indoor

u

nit

Detected indoor

a

ddre

ss

Indoor overflow

pro

b

lem

All

s

top

• Flo

a

t

s

witch oper

a

te

s

.

• Flo

a

t

s

witch circ

u

it i

s

open-

circ

u

ited or di

s

connected

a

t connector.

P10

P10

• Check connection of f

a

n

connector

a

nd wiring.

• Check for defect in f

a

n motor.

• Check for defect in indoor

P.C.

b

o

a

rd.

• Check imp

a

ct of o

u

t

s

ide

a

ir

tre

a

tment (OA).

Indoor

u

nit

Indoor f

a

n

motor pro

b

lem

S

top of

corre

s

ponding

u

nit

• Motor

s

peed

me

asu

rement

s

contin

u

o

us

ly

devi

a

te from t

a

rget v

a

l

u

e.

• Overc

u

rrent protection i

s

a

ctiv

a

ted.

P12

—

—

• Check f

u

ll-clo

s

e oper

a

tion

of o

u

tdoor PMV (1, 3, 4).

• Check for defect in Pd or

P

s

s

en

s

or.

• Check g

as

ba

l

a

ncing

circ

u

it (

S

V2) for clogging.

• Check

ba

l

a

nce pipe.

• Check

S

V3B circ

u

it for

clogging.

• Check defect in o

u

tdoor

P.C.

b

o

a

rd (I/F).

• Check c

a

pill

a

ry of oil

s

ep

a

r

a

tor oil ret

u

rn circ

u

it

for clogging.

• Check for le

a

k

a

ge of check

v

a

lve in di

s

ch

a

rge pipe

convergent

s

ection.

I/F

O

u

tdoor liq

u

id

ba

ckflow

detection

pro

b

lem

All

s

top

<D

u

ring cooling oper

a

tion>

When

s

y

s

tem i

s

in cooling

oper

a

tion, high pre

ssu

re i

s

detected in follower

u

nit th

a

t

h

as

b

een t

u

rned off.

<D

u

ring he

a

ting oper

a

tion>

When

s

y

s

tem i

s

in he

a

ting

oper

a

tion, o

u

tdoor PMV 1 or

3 contin

u

o

us

ly regi

s

ter

s

opening of 300p or le

ss

while

u

nder

su

perhe

a

t

control.

P13

P13

—

• Check for in

su

fficiency in

refriger

a

nt q

ua

ntity.

• Check o

u

tdoor

s

ervice

v

a

lve

s

(g

as

s

ide, liq

u

id

s

ide) to confirm f

u

ll

opening.

• Check PMV

s

(PMV1, 3) for

clogging.

• Check re

s

i

s

t

a

nce

ch

a

r

a

cteri

s

tic

s

of T

S

1

s

en

s

or.

• Check for defect in 4-w

a

y

v

a

lve.

• Check

S

V4 circ

u

it for

le

a

k

a

ge

I/F

01:

T

S

condition

G

as

le

a

kdetection

(T

S

1 condition)

All

s

top

Protective

s

h

u

tdown d

u

e to

sus

t

a

ined

su

ction

temper

a

t

u

re

a

t or

ab

ove

j

u

dgment criterion

for

a

t le

as

t 10 min

u

te

s

i

s

repe

a

ted fo

u

r time

s

or more.

<T

S

tro

ub

le j

u

dgment criterion>

In cooling oper

a

tion: 60 ˚C

In he

a

ting oper

a

tion: 40 ˚C

P15

P15

• Check for in

su

fficiency in

refriger

a

nt q

ua

ntity.

• Check PMV

s

(PMV 1, 3)

for clogging.

• Check re

s

i

s

t

a

nce

ch

a

r

a

cteri

s

tic

s

of TD1

a

nd

TD2

s

en

s

or

s

.

• Check indoor filter for

clogging.

• Check piping for clogging.

• Check

S

V4 circ

u

it (for

le

a

k

a

ge or coil in

s

t

a

ll

a

tion

tro

ub

le).

• Check o

u

tdoor

s

ervice

v

a

lve

s

(g

as

s

ide, liq

u

id

s

ide) to confirm f

u

ll

opening.

• Check o

u

tdoor PMV

s

(PMV1, 3, 4) for clogging.

• Check re

s

i

s

t

a

nce

ch

a

r

a

cteri

s

tic

s

of TD2

s

en

s

or.

• Check for defect in 4-w

a

y

v

a

lve.

• Check

S

V4 circ

u

it for

le

a

k

a

ge.

• Check

S

V4 circ

u

it (for

wiring or in

s

t

a

ll

a

tion tro

ub

le

involving

S

V41

a

nd

S

V42).

I/F

Di

s

ch

a

rge

temper

a

t

u

re

TD2 pro

b

lem

All

s

top

Di

s

ch

a

rge temper

a

t

u

re

(TD2) exceed

s

115 ˚C.

P17

P17

—

I/F

02:

TD condition

G

as

le

a

k

detection

(TD condition)

All

s

top

Protective

s

h

u

tdown d

u

e to

sus

t

a

ined di

s

ch

a

rge

temper

a

t

u

re (TD1 or TD2)

a

t or

ab

ove 10

8

˚C for

a

t

le

as

t 10 min

u

te

s

i

s

repe

a

ted

fo

u

r time

s

or more.

Main

remote

controller

Outdoor 7-

s

e

g

ment di

s

play

Check

code

S

ub-code