Programming the

Channels,

continued

• When entering single-digit

channels, press 0 first. For

example, to select channel 8,

press 0 then 8.

• When entering three-digit

channels, press the +100

button on the remote control

first. For example, to select

channel 104, press +100, then

press 0, then 4.

´

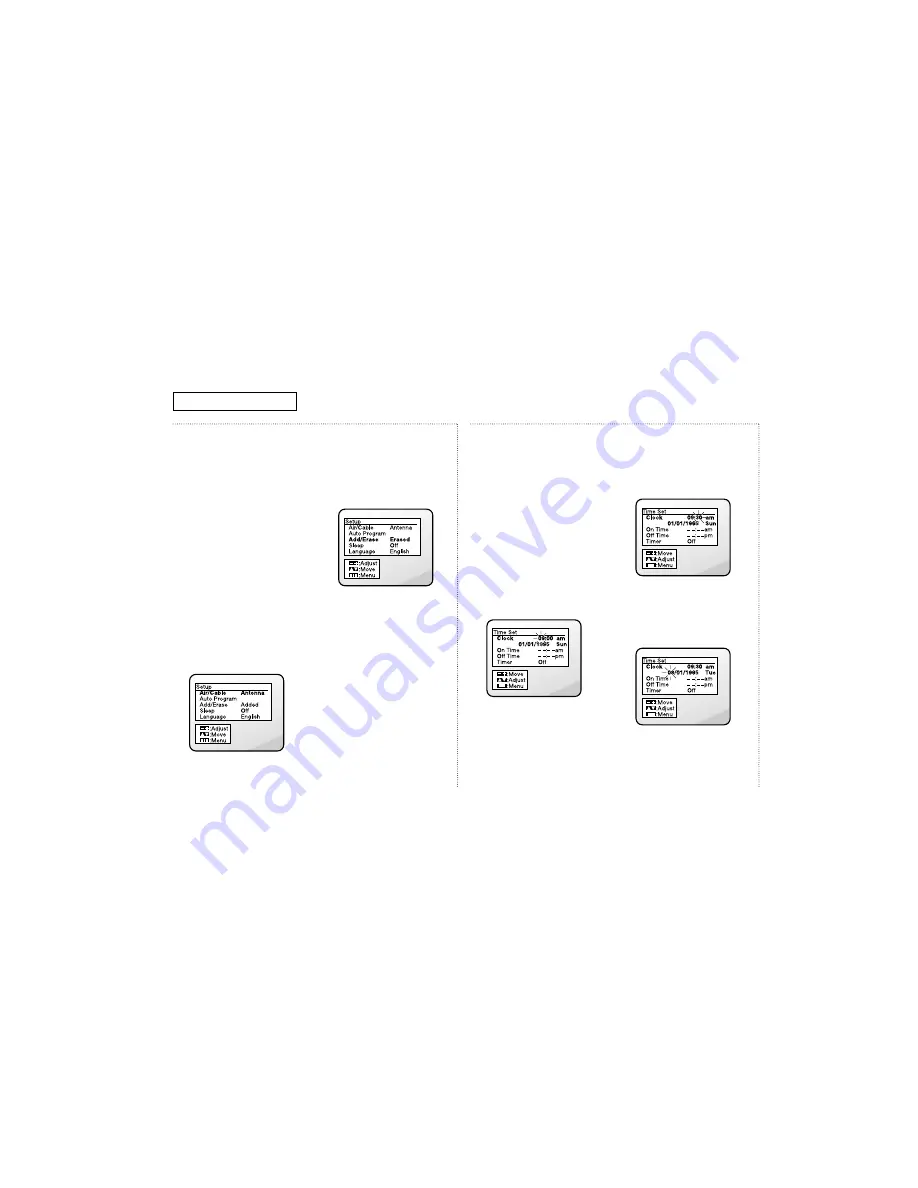

Press MENU to display the

menu.

ˇ

Press CH

▼

until “Setup” is

highlighted.

¨

Press VOL+ to display the

Setup menu.

ˆ

Press CH

▼

until “Add/Erase”

is highlighted.

Ø

If you want to:

• Add a channel:

Press VOL+ or VOL– to

display “Added.”

• Erase a channel:

Press VOL+ or VOL– to

display “Erased.”

You can still view a channel that

is not stored in memory by using

the number buttons to select the

channel directly.

Setting the Clock

and Calendar

To record programs while you

are away, or to use the sleep

timer, you must first set the

clock and calendar.

Œ

With the main menu

displayed, press CH

▼

until

“Time Set” is highlighted.

´

Press VOL+.

The Time Set menu appears.

Setting the time

Œ

Press VOL+.

The hours will blink.

´

Press CH

▲

or CH

▼

to set the

current hour.

✔

Be sure to set the correct time

of day (am or pm), which

appears to the right of the

minutes.

ˇ

Press VOL+.

The minutes will blink.

¨

Press CH

▲

or CH

▼

to set the

current minute.

Setting the date

Œ

Press VOL+.

The month will blink.

´

Press CH

▲

or CH

▼

to set the

current month.

3-11

C

HAPTER

T

HREE

: TV O

PERATION

TV O

PERATION

Summary of Contents for M-V19H01

Page 9: ...Color TV VCR Combination OWNER S MANUAL M V19H01 ...

Page 46: ...TOSHIBA AMERICA CONSUMER PRODUCTS INC ...

Page 131: ...Troubleshooting 7 7 7 8 No Playback ...

Page 134: ...Troubleshooting 7 10 7 13 Reverse Direction Search Screen Doesn t Operate ...

Page 135: ...Troubleshooting 7 11 7 14 Tape Doesn t Load ...

Page 136: ...Troubleshooting 7 12 7 15 Capstan Doesn t Rotate ...

Page 137: ...Troubleshooting 7 13 7 16 Cylinder Doesn t Rotate ...

Page 138: ...Troubleshooting 7 14 7 17 No Picture During Playback ...

Page 139: ...Troubleshooting 7 15 7 18 No Picture During Record ...

Page 140: ...Troubleshooting 7 16 7 19 No Color During Playback ...

Page 141: ...Troubleshooting 7 17 7 20 No Color During Record ...

Page 142: ...MEMO 7 18 ...

Page 163: ...Schematic Diagrams 13 1 13 Schematic Diagrams 13 1 VCR SECAM BLOCK ...

Page 164: ...Schematic Diagrams 13 2 13 2 A V BLOCK ...

Page 165: ...Schematic Diagrams 13 3 13 3 POWER BLOCK ...

Page 166: ...13 4 13 4 MAIN BLOCK ...