2-3-4

N25E1FLMA

5. To shift the CTL waveform, press [PROGRAM

]

or [PROGRAM

] button. Then make sure that

the maximum output position of PB FM envelope

signal becomes within

±

2ms from preset position.

6. Set the Tracking Control Circuit to the preset posi-

tion by pressing [PROGRAM

] button and then

[

B

] (VCR) button on the unit.

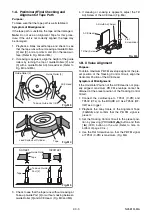

1-C. Checking/Adjustment of Envelope

Waveform

Purpose:

To achieve a satisfactory picture, adjust the Guide

Rollers so that the PB FM envelope becomes as flat

as possible.

Symptom of Misalignment:

If the envelope output is poor, noise will appear in the

picture. The tracking will then lose precision and the

playback picture will be distorted by any slight varia-

tion of the Tracking Control Circuit.

1. Connect the oscilloscope to TP301 (C-PB) on the

BOARD AV. Use TP504 (RF-SW) as a trigger.

2. Playback the Gray Scale on the Alignment Tape

(FL6NS8). Set the Tracking Control Circuit to the

preset position by pressing [PROGRAM

] button

and then [

B

] (VCR) button on the unit. Adjust the

height of Guide Rollers [2] and [3] (Fig. M3, Page

2-3-3) watching the oscilloscope display so that the

envelope becomes as flat as possible. To do this

adjustment, turn the top of the Guide Roller with

the Guide Roller Adj. Screwdriver.

3. If the envelope is as shown in Fig. M8, adjust the

height of Guide Roller [2] (Refer to Fig. M3) so that

the waveform looks like the one shown in Fig. M10.

4. If the envelope is as shown in Fig. M9, adjust the

height of Guide Roller [3] (Refer to Fig. M3) so that

the waveform looks like the one shown in Fig. M10.

5. When Guide Rollers [2] and [3] (Refer to Fig. M3)

are aligned properly, there is no envelope drop

either at the beginning or end of track as shown in

Fig. M10.

Note: Upon completion of the adjustment of Guide

Rollers [2] and [3] (Refer to Fig. M3), check the X

Value by pushing the [PROGRAM

] or [PROGRAM

] buttons on the unit alternately, to check the sym-

metry of the envelope. Check the number of pushes to

ensure preset position. The number of pushes of the

[PROGRAM

] button on the unit to achieve 1/2 level

of envelope should match the number of pushes of the

[PROGRAM

] button on the unit from center. If

required, redo the “X Value Alignment.”

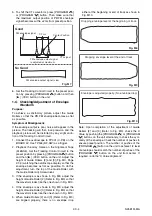

No Good

Good

FM envelope output signal is low.

2ms

FM envelope signal

CTL signal

Center Position

FM envelope output signal

is adjusted at maximum.

Fig. M7

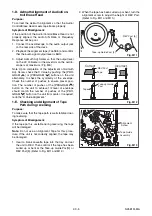

Dropping envelope level at the beginning of track.

Fig. M8

Dropping envelope level at the end of track.

Fig. M9

Envelope is adjusted properly. (No envelope drop)

Fig. M10

Summary of Contents for DVR19DTKB2

Page 4: ...1 1 1 E9TK3SP SPECIFICATIONS ...

Page 58: ...1 14 3 NOTE BOARD MEANS PRINTED CIRCUIT BOARD E9TK3SCAV1 AV 1 9 Schematic Diagram VCR Section ...

Page 60: ...1 14 5 NOTE BOARD MEANS PRINTED CIRCUIT BOARD E9TK3SCAV3 AV 3 9 Schematic Diagram VCR Section ...

Page 61: ...1 14 6 NOTE BOARD MEANS PRINTED CIRCUIT BOARD E9TK3SCAV4 AV 4 9 Schematic Diagram VCR Section ...

Page 62: ...1 14 7 NOTE BOARD MEANS PRINTED CIRCUIT BOARD E9TK3SCAV5 AV 5 9 Schematic Diagram VCR Section ...

Page 63: ...1 14 8 NOTE BOARD MEANS PRINTED CIRCUIT BOARD E9TK3SCAV6 AV 6 9 Schematic Diagram VCR Section ...

Page 64: ...1 14 9 NOTE BOARD MEANS PRINTED CIRCUIT BOARD E9TK3SCAV7 AV 7 9 Schematic Diagram VCR Section ...

Page 89: ...1 17 3 DVDP_TI Push close 0 08 V 0 02 s Push Close detection Threshold level ...

Page 97: ...1 20 4 E9TK3PEX Packing X 2 X 3 X 6 X1 Upper Side Lower Side FRONT ...

Page 123: ......