3. APPEARANCE

ENGLISH VERSION

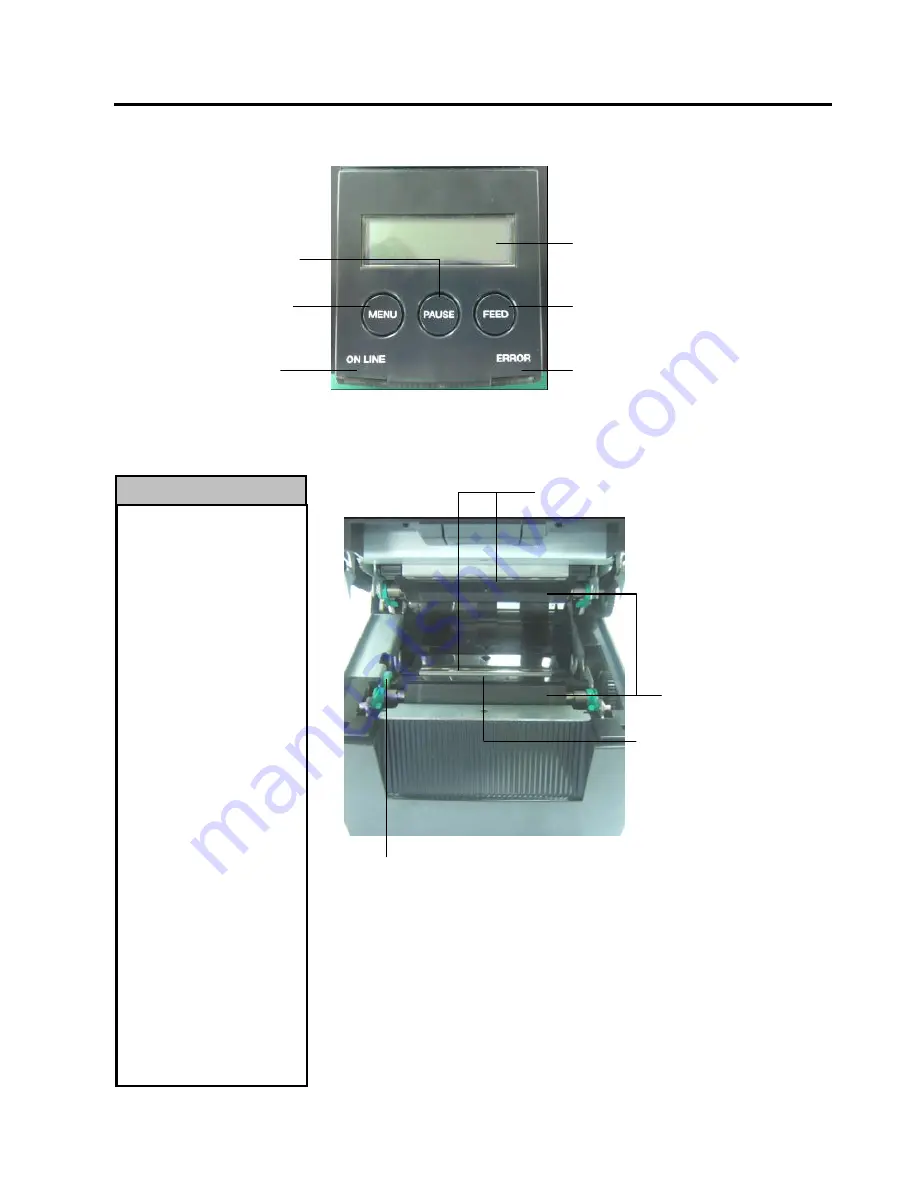

3.4 Operation Panel

E3-2

3.4 OPERATION PANEL

(Refer to Section 4 for further information about the Operation Panel.)

3.5 INTERIOR

1.

Do not touch the Print Head

or around it just after

printing. You may get

burned as the Print Head

becomes very hot during

printing.

2.

Do not touch any moving

parts. To reduce the risk of

fingers, jewellery, clothing,

etc., being drawn into the

printer.

3.

To avoid injury, be careful

not to trap your fingers

while opening or closing the

cover.

AVERTISSEMENT

1.

Ne touchez pas à la tête

d'impression ou autour juste

après l'impression. Vous

pouvez être brûlé puisque la

tête d'impression devient très

chaude pendant

l'impression..

2.

Ne touchez à aucune pièce

en mouvement. Assurezvous

d’avoir bien arrêté

l’imprimante avant de

charger le média, afin de

réduire le risque d’avoir vos

doigts.

3.

Pour éviter la blessure,

soyez prudent de ne pas

coincer vos doigts pendant

que vous ouvrez ou fermez le

boîtier.

WARNING!

ONLINE LED

(Blue)

ERROR LED

(Orange)

LCD Message Display

[

FEED

] Key

[

MENU

] Key

[

PAUSE

] Key

Platen

Label Gap

Sensor & Black

Mark Sensor

Print Head Element

Sensor Knob