Mar. 1998 © TOSHIBA

5 - 3

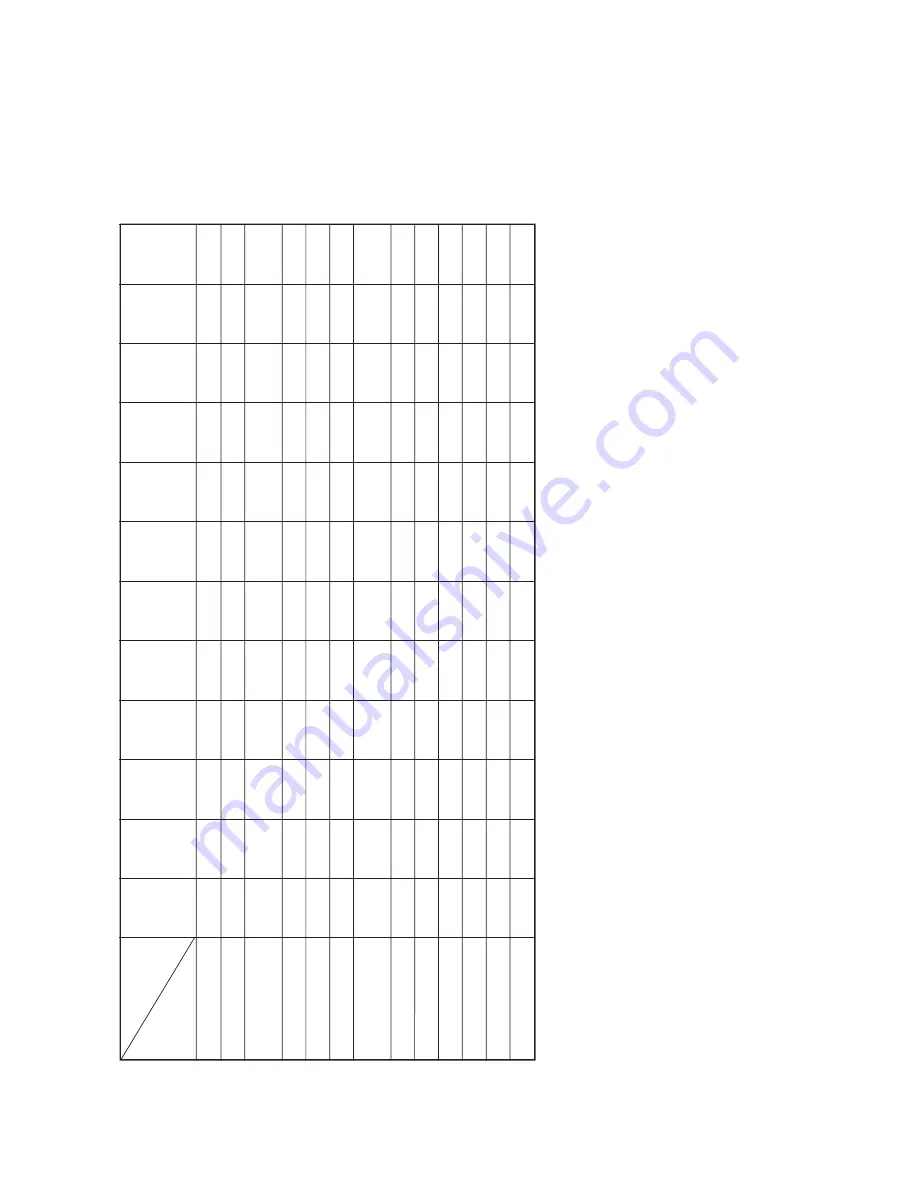

15501560 DISPLAY

5.3

Relationship between Machine Condition and Operator’s Action

W

arming up

_

___

___

____

_

Ready

_

___

___

____

_

Reproduction-ratio

–

___

___

____

_

changing

Copying

–

_

––

__

–

__

––

x

(4)

Add paper

–

___

___

____

_

Add toner

–

___

___

____

_

Key copy counter not

–

___

___

____

_

inserted (optional)

Bypass misfeed

–

___

_

––

____

–

Replace toner bag

–

–

__

___

____

_

Clear paper

–

––––

–––

–––

–

Service call

–

––––

–––

–––

–

Interrupt mode

_

––

_

___

__

––

_

Energy-saving mode

_

––––

–––

–

_

––

REPRO-

DUCTION-

RA

TIO

selection

key

CLEAR/

ST

OP

key

Digital

keys

key

AUT

O

EXPOSURE

key

(PHOT

O key)

Manual

exposure

Photo

exposure

CASSETTE

SELECTION

key

INTER-

RUPT

key

ENERGY

SA

VER

key

Condition

Operation

_

: Machine operates or indicates in accordance with the operator

’s

action.

–: Operation is ignored.

(1)

By pressing the ENERGY

SA

VER key or the PRINT

key

, the energy-saving mode will be cancelled.

(2)

During copying, avoid changing exposure as far as possible.

(3)

The function of the CLEAR/ST

OP

key changes in the following manner according to the machine status.

During copying

.........

Interruption of the copying (Stop function

.....

The copy quantity indicator will not change.)

When not copying

....

When pressed once, the copy quantity indicator returns to “1”.

(4)

During copying, avoid sheet bypass feeding because of possible paper jamming.

(Note)

The interrupt mode will be automatically cancelled when the machine is not used for 45 seconds.

DUAL-

P

AGE

COPY

key

Sheet

bypass

Summary of Contents for 1550

Page 11: ...1550 1560 GENERAL 2 4 Mar 1998 TOSHIBA ...

Page 112: ...1550 1560 DRUM 9 12 Mar 1998 TOSHIBA 1 16 48 CLK SI1 LT OUT1 1 2 64 Timing chart ...

Page 167: ...Mar 1998 TOSHIBA 13 25 1550 1560 OPTIONAL 13 7 4 PC board assembly PWA F PFU ...

Page 188: ...Mar 1998 TOSHIBA 14 21 1550 1560 CIRCUIT DIAGRAMS Control Panel Circuit PWA F PNL 4 4 ...

Page 189: ...1550 1560 CIRCUIT DIAGRAMS 14 22 Mar 1998 TOSHIBA 14 4 Fuser Circuit PWA F FUS ...