Adjusting the Shift Cables

Service Interval:

After the first 10 hours

Every 200 hours

1. Move shift lever to the Neutral position.

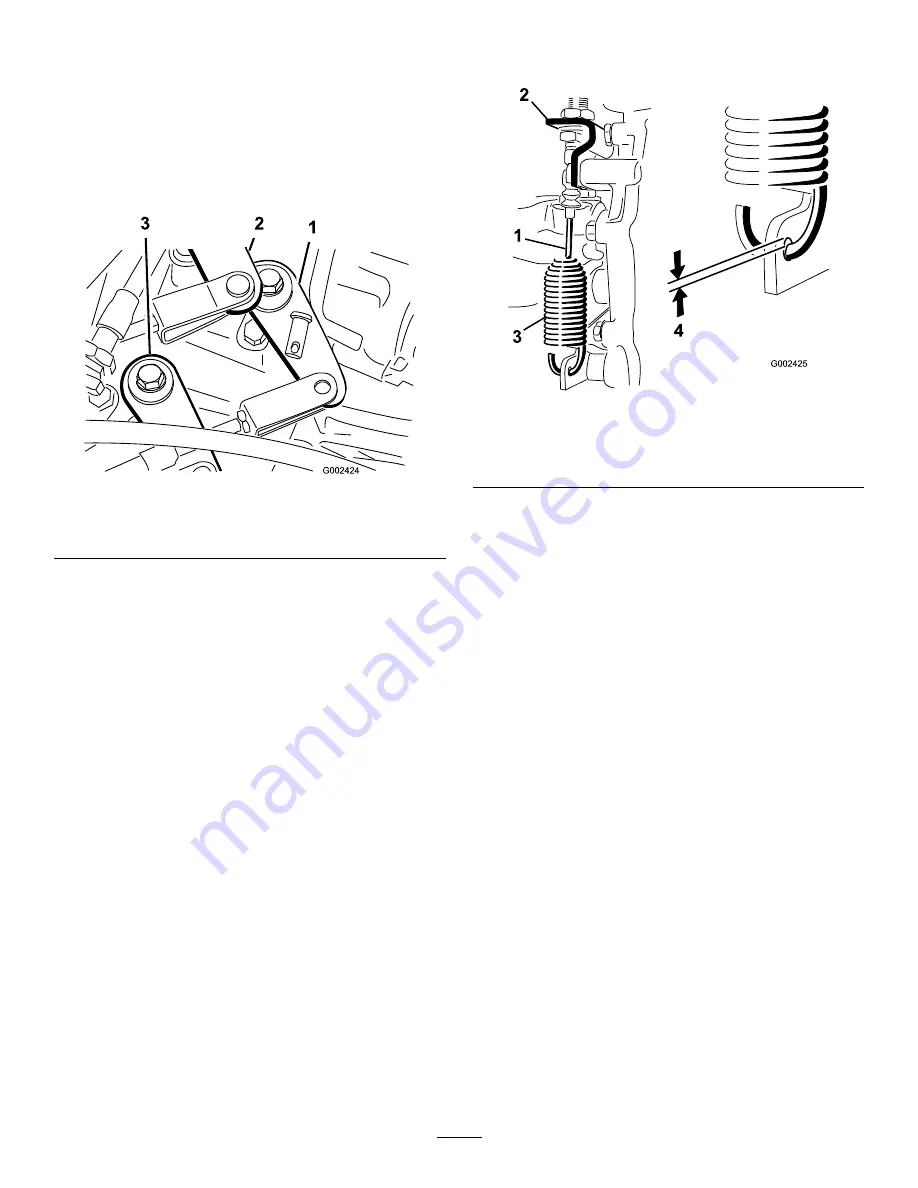

2. Remove the clevis pins securing the shift cables to

the transaxle shift arms (Figure 55).

Figure 55

1.

Shift arm (1st—Rev.)

3.

Shift arm (High—low)

2.

Shift arm (2nd—3rd)

3. Loosen the clevis jam nuts and adjust each clevis

so cable free play is equal forward and backward

relative to the hole in the transaxle shift arm (with

the transaxle lever free play taken up in the same

direction).

4. Install the clevis pins and tighten the jam nuts when

finished.

Adjusting the High–Low Cable

Service Interval:

Every 200 hours

1. Remove the clevis pin securing the High–Low cable

to the transaxle (Figure 55).

2. Loosen the clevis jam nut and adjust the clevis

so that the clevis hole aligns with the hole in the

transaxle bracket.

3. Install the clevis pin and tighten the jam nut when

finished.

Adjusting Differential Lock

Cable

Service Interval:

Every 200 hours

1. Move the differential lock lever to the Off position.

2. Loosen the jam nuts securing the differential lock

cable to the bracket on the transaxle (Figure 56).

Figure 56

1.

Differential lock cable

3.

Spring

2.

Transaxle bracket

4.

0.01 to 0.06 inch (0.25 to

1.5 mm) gap

3. Adjust the jam nuts to obtain a 0.01 to 0.06 inch

(0.25 to 1.5 mm) gap between the spring hook and

the O.D. of the hole in the transaxle lever.

4. Tighten the jam nuts when finished.

Inspecting the Tires

Service Interval:

Every 100 hours

Operating accidents, such as hitting curbs, can damage a

tire or rim and also disrupt wheel alignment, so inspect

tire condition after an accident.

Check the tire pressure frequently to ensure proper

inflation. If the tires are not inflated to the correct

pressure, the tires will wear pre maturely.

Figure 57 is an example of tire wear caused by under

inflation.

47