Drive System

Maintenance

Servicing the Tires

WARNING

Exploding tires and/or rim parts can cause injury

or death.

Keep yourself and others out of the area of danger.

Stand on the tread side of the tire. Always fill

the tires to the correct air pressure, and follow

the instructions in this manual for adding air or

servicing the tires.

WARNING

Do not weld the wheel or rim with the tire installed.

Welding with an explosive air/gas mixture can

ignite, causing serious injury or death, regardless of

whether the tire is inflated or deflated.

Removing the air or breaking the bead is not

adequate; you must completely remove the tire from

the rim before welding.

WARNING

An explosive separation of the tire and/or rim parts

can cause injury or death.

Have a qualified tire mechanic service the tire.

Checking the Tires and Wheels

Service Interval:

Before each use or daily

1.

Check each tire for embedded objects, separated plies,

missing tread, bulges, or a damaged bead, and replace

it, if necessary.

2.

Check each wheel for signs of unusual bending or

damage, and replace it, if necessary.

Maintaining the Air Pressure in the

Tires

Service Interval:

Every 50 hours

Important:

Maintain the air pressure in the tires at 310

kPa (45 psi).

1.

Measure the air pressure in the tires; if the tire pressure

is not at the recommended pressure, complete the rest

of this procedure.

Important:

Use an air hose with a remote shutoff

valve and a self-locking chuck.

Note:

Before you add air, ensure that the tire is

properly installed on the machine, or put the wheel in a

restraining device, such as a tire inflation cage.

2.

Remove the cap from the valve stem.

3.

Attach the self-locking chuck of the air hose to the

valve stem.

4.

When inflating the tire while it is mounted to the

machine, stand behind the tread of the tire.

Note:

Ensure that all persons are away from the side

of the tire before you start to add air.

5.

Open the remote shutoff valve to inflate the tire to the

specified pressure, then close the valve.

Important:

Do not inflate the tire more than the

recommended pressure.

6.

Remove the air chuck from the valve stem.

7.

Install the cap on the valve stem.

Maintaining the Tires and Wheels

Always have a qualified tire technician service the tires and

wheels of this machine. To prevent accidents, use a restraining

device (such as a tire inflation cage), the correct equipment,

and the correct procedure.

Important:

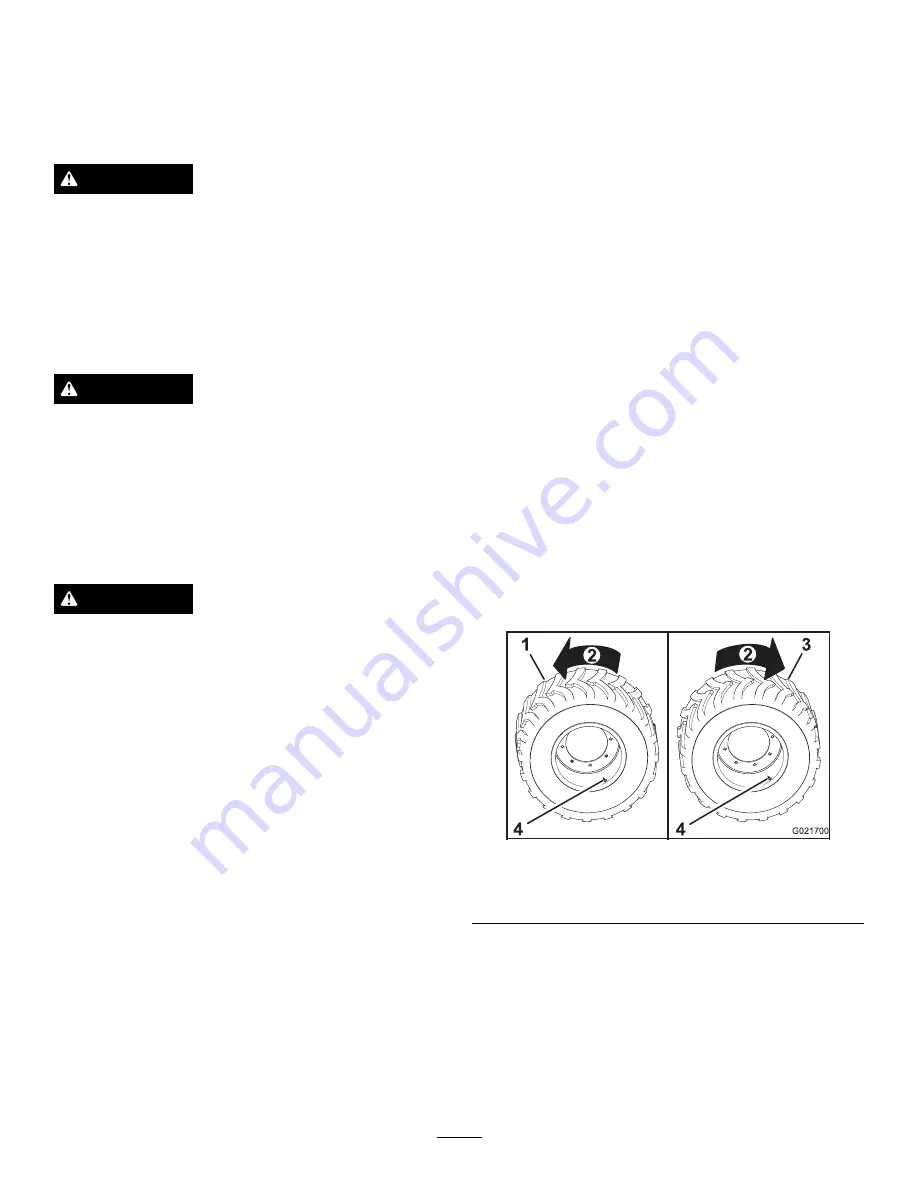

There are 2 different tire-tread pattern and

wheel combinations; the left-side tires and the right-side

tires are different. Ensure that the tread direction of the

tire and the valve stem in the wheel are correctly aligned

before installing the tire to the rim.

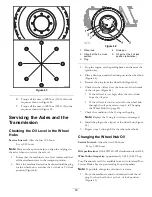

Figure 62

1.

Left-side tire

3.

Right-side tire

2.

Forward

4.

Valve stem

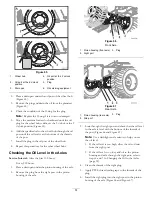

Torquing the Wheel Nuts

1.

Ensure that the mounting flange of the wheel is flush

against the mounting flange of the axle.

2.

Incrementally torque the wheel nuts for each wheel

as follows:

A.

Torque the all wheel nuts to 100 N-m (75 ft-lb) in

the sequence shown in Figure 63.

49

Summary of Contents for RT600

Page 71: ...Notes 71...