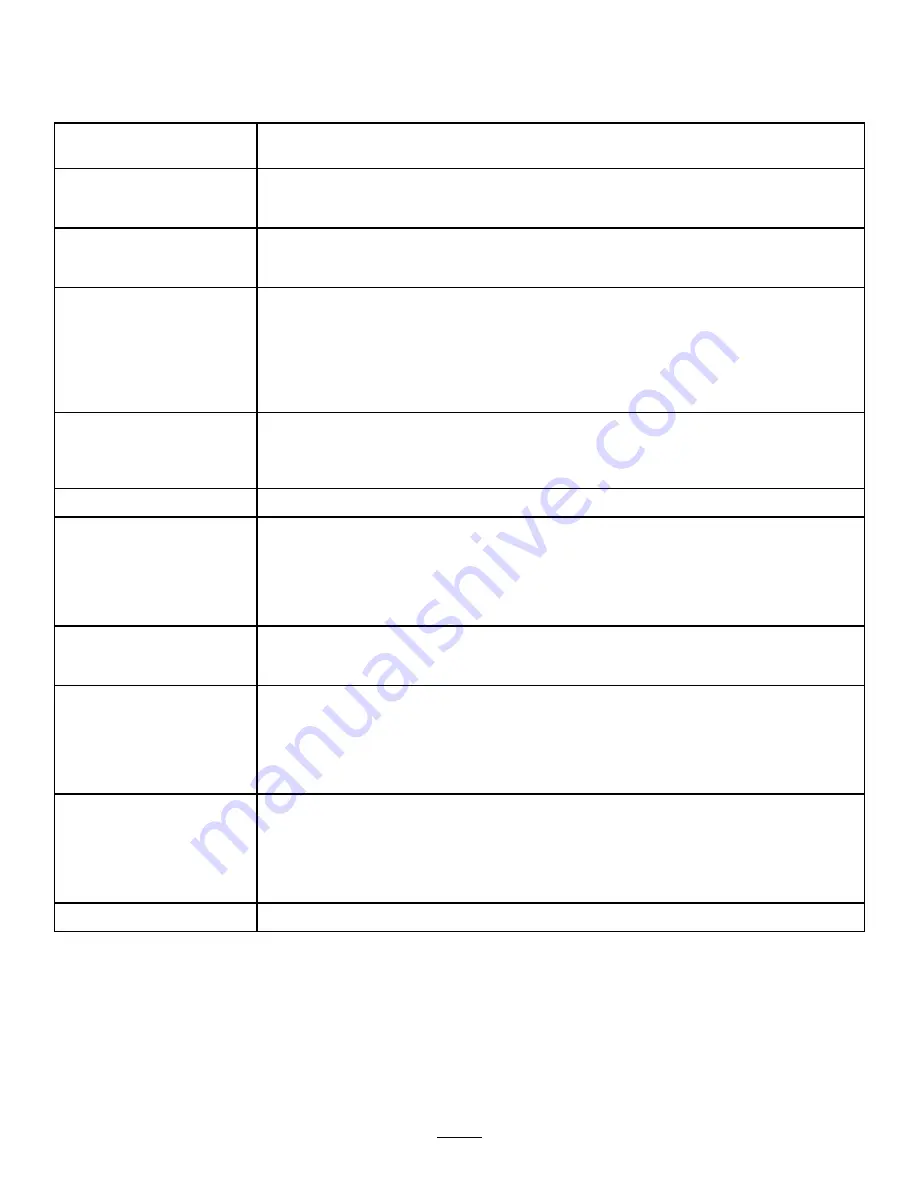

Maintenance

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

Maintenance Procedure

After the first 100 hours

• Check the oil level in the wheel hubs.

• Check the oil level in the front and rear axles.

• Check the oil level in the transmission.

After the first 200 hours

• Change the wheel hub oil.

• Change the oil in the axles.

• Change the oil in the transmission and rear axle.

Before each use or daily

• Check the engine oil level.

• Check the hydraulic fluid level in the reservoir.

• Grease the machine.

• Check the engine oil level.

• Check the restricted air-cleaner light for a restricted air cleaner.

• Check the tires and wheels for damage.

• Check the coolant level in the reservoir.

Every 50 hours

• Check and clean the dust valve.

• Check the fuel-water separator for water and sediment.

• Maintain the proper air pressure in the tires.

• Check the coolant level in the radiator.

Every 200 hours

• Grease the front and rear axles.

Every 250 hours

• Change the engine oil.

• Change the engine oil filter.

• Check the oil level in the wheel hubs.

• Check the oil level in the front and rear axles.

• Check the oil level in the transmission.

• Check the condition of the engine drive belt.

Every 300 hours

• Clean the axle breather for each axle.

• Check the condition of the coolant system components. Clean dirt and debris from

them and repair or replace the components as necessary.

Every 500 hours

• Grease the drive shaft.

• Replace the secondary fuel filter.

• Replace the primary fuel filter.

• Change the hydraulic-pressure filter.

• Change the hydraulic-return filter.

• Check and maintain the ROPS; check it after an accident.

Every 1,000 hours

• Change the wheel hub oil.

• Change the oil in the axles.

• Change the oil in the transmission and rear axle.

• Check the concentration of the coolant.

• Check the tension on the engine drive belt.

• Change the hydraulic fluid and clean the breather.

Every 2,000 hours

• Clean the cooling system.

33

Summary of Contents for RT600

Page 71: ...Notes 71...