________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

________________________________________________________________________________________________________________________________________________________

Cutting Unit Operation Problems

Condition

Possible Cause

Correction

Engine continues to run (but

should not) when cutting unit

clutch switch is ON with no opera

tor on the seat.

Seat switch plunger depressed

with no operator on seat.

Check for seat support spring

that is broken, missing or stuck in

down position.

Check for binding seat pivot

hinge.

Check for waterlogged seat.

Seat switch faulty or out of adjust

ment.

Test seat switch. Adjust or re

place if faulty.

Cutting units run (but should not)

Cutting unit interlock switch faulty.

Test switch and replace if faulty.

when raised, but shut off with cut-

Make sure wires are connected

ting unit clutch switch.

to “COMMON” and “NORMALLY

OPEN” (N.O.) terminals.

Cutting units shut off when

Cutting unit clutch switch faulty.

Test switch. Replace if faulty.

raised, but do not shut off with

cutting unit clutch switch.

Cutting units do not engage.

“ACC” fuse open. (NOTE: Hourme

ter and temp. gauge will also fail to

operate.)

Check fuse and replace if fuse is

open. If fuse burns out often, find

and correct cause.

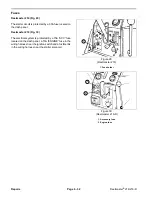

Cutting unit clutch switch faulty.

Test switch. Replace if faulty..

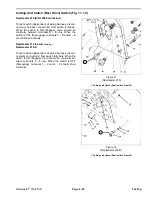

Cutting unit clutch switch wiring

loose, corroded or damaged.

Repair wiring.

Cutting unit interlock switch faulty.

Test switch and replace if faulty.

Make sure wires are connected

to “COMMON” and “NORMALLY

OPEN” (N.O.) terminals.

Cutting unit interlock switch wiring

loose, corroded or damaged.

Repair wiring.

Clutch faulty or out of adjustment.

Test clutch. Make sure clutch air

gap is properly adjusted..

Clutch wiring loose, corroded or

damaged.

Repair wiring.

Troubleshooting

(Reelmaster 216-D)

Page 6 - 18

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

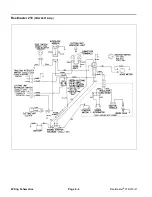

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...