Set Up and Adjustments

Adjustment Summary and Check List

DETAILED ADJUSTMENT INSTRUCTIONS FOLLOW

THIS SUMMARY AND CHECK LIST

. Study this informa

tion and refer to it often to get maximum life and per

formance from the cutting units.

Daily Performance Checks

NOTE: It is not necessary to remove the cutting units

from the traction unit to perform these daily checks. It is

recommended that mowers be washed after each use.

Always remove key from ignition switch when working

on the machine.

1. Purge all water and debris from all of the bearings by

greasing them. Use No. 2 multi-purpose lithium base

grease.

2. Visually check for sharp reel and bedknife.

•

Remove burrs, nicks, and rounded edges.

3. Lower cutting units to ground (setting on rollers) and

remove belt tension. Rotate the reel by hand. TURN

ADJUSTING KNOB ONE (1) CLICK AT A TIME UNTIL

FIRST CONTACT BETWEEN REEL AND BEDKNIFE IS

FELT AND HEARD THEN TIGHTEN ONE (1) MORE

CLICK TO GET LIGHT CONTACT

*.

•

No contact will dull the cutting edges.

•

Excessive contact accelerates wear; quality of cut

may be adversely affected.

* It is best to make the reel to bedknife adjustment

in the morning, immediately before each day of

mowing.

Weekly Checks

1. Check reel bearing condition — rotate reel by hand

with no bedknife to reel contact.

2. Make sure bedknife adjustment knob/pivot assembly

is held FIRMLY in place between bedbar yoke.

3. Using a gauge bar, verify correct height of cut setting.

Monthly Adjustments

NOTE: Remove cutting unit from traction unit.

1. Visually check for sharp reel and bedknife. Backlap

or grind reel and bedknife if necessary.

2. Set height of cut adjustment and level rear roller.

3. Adjust bedknife parallel to reel.

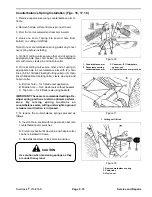

5. Floating cutting units only – use gauge bar to verify

height of cut adjustment and adjust front roller.

6. Adjust roller scraper (if equipped) to 1/32 in. from

roller.

* Check to make sure both front and rear rollers con

tact the ground for their entire length and that the

bedknife cutting edge is parallel with the ground. Do

adjustments again if necessary.

7. Set comb (if equipped) for desired action on turf.

8. After installing cutting units on machine, lower cutting

units to ground and adjust reel to bedknife contact (see

Step 3 under Daily Performance Checks).

Special Notes

1. Replace the bedbar bushings and nylon flange bush

ings every two years.

2. A “rifled” reel and/or bedknife must be corrected by

grinding.

3. After extended running, a ridge will eventually de

velop at both ends of the bedknife. These ridges must

be ground off or filed flush with cutting edge of bedknife

to assure smooth operation.

4. Adjust large jam nut on reel shaft to get 0.060 in.

clearance from reel blades to end of bedbar when

capscrew on end of reel shaft is tightened. Tighten

capscrew on end of reel shaft to 35 ft-lb.

5. To get proper bearing alignment, leave nuts on bear

ing flanges loose and adjust reel parallel to bedknife.

Rotate reel by hand and tap end of reel shaft with a soft

face hammer so self-aligning reel bearings can find the

proper alignment position. Tighten nuts to clamp and

retain bearings.

Set Up and Adjustments

Page 9 - 6

Reelmaster

®

216/216-D

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...