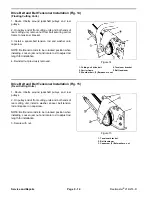

Height of Cut Adjustment and Leveling Rear Roller (Fig. 5)

(Fixed Cutting Units)

1. Position cutting unit on flat level surface or board.

2. Slightly loosen (crack) nuts securing roller brackets

to angle brackets.

3. Adjust support capscrews to achieve 5/8

±

1/16 in.

dimension between Height-of-Cut support and roller

bracket (2 places).

4. Remove hairpin cotters securing Height-of-Cut pins

and reinstall in hole at desired setting as indicated on

Height-of-Cut plate.

5. Use a gage block with a height equal to the desired

height-of-cut and position it against the front edge of the

bedknife at one end. Turn the support capscrew to

adjust the height of the bedknife equal to the gage block.

6. Repeat the procedure at the other end, then recheck

the original end.

7. Tighten nuts securing roller brackets.

8. After initial set-up, height-of-cut may be changed by

repositioning Height-of-Cut pins to desired setting.

Figure 5

1. Roller bracket

2. Angle bracket

3. Height of cut pin

4. Support capscrew

Reelmaster

®

216/216-D

Page 9 - 9

Set Up and Adjustments

Summary of Contents for reelmaster 216

Page 2: ...This page is blank ...

Page 4: ...This page is blank ...

Page 8: ...Safety Instructions Page 1 4 Reelmaster 216 216 D ...

Page 12: ...Torque Specifications Page 2 4 Rev B Reelmaster 216 216 D ...

Page 26: ...Adjustments Page 4 4 Reelmaster 216 216 D ...

Page 40: ...Troubleshooting Page 5 14 Reelmaster 216 216 D ...

Page 42: ...Troubleshooting Page 5 16 Reelmaster 216 216 D ...

Page 72: ...Repairs Page 5 46 Reelmaster 216 216 D ...

Page 75: ...Reelmaster 216 S N 10001 19999 Reelmaster 216 216 D Page 6 3 Wiring Schematics ...

Page 76: ...Reelmaster 216 S N 20001 Up Wiring Schematics Page 6 4 Reelmaster 216 216 D ...

Page 77: ...Reelmaster 216 D Reelmaster 216 216 D Page 6 5 Wiring Schematics ...

Page 114: ...Repairs Page 7 8 Reelmaster 216 216 D ...

Page 124: ...Repairs Page 8 10 Reelmaster 216 216 D ...

Page 143: ...This page is blank ...