Installation Instructions

5

1

2

Figure 8

1.

Engine

2.

Engine screw (3)

Note: Figure 8 shows the GTS 150 engine. The GTS 200

engine is not shown.

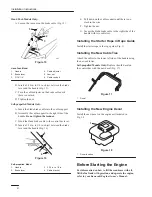

Removing the Discharge Tunnel

Assembly

1. Remove two capscrews, two flat washers, two

locknuts, a 1/2 in. hex head washer screw, and a 3/4 in.

hex head washer screw that secure the discharge tunnel

assembly to the lawn mower housing (Fig. 9).

2

3

4

5

6

1

8

7

9

10

12

11

Figure 9

1.

Discharge tunnel

2.

Capscrew (2)

3.

Flat washer (2)

4.

Locknut (2)

5.

Hex head washer screw

(1/2” long)

6.

Hex head washer screw

(3/4” long)

7.

Spring bracket

8.

Spring extension

9.

Latch plate

10. Self-tapping screw (2)

11. Door retainer

12. Discharge door assembly

Note: Keep all these items for the installation.

2. Lift off the discharge tunnel assembly (Fig. 9).

3. Remove the spring bracket and the spring extension

(Fig. 9).

Note: Keep these items for the installation.

4. Discard the discharge tunnel assembly (Fig. 9).

Conversion Kit Installation

Installing the New Discharge Tunnel

1. Position the new discharge tunnel on the lawn mower

deck. Align the holes in the discharge tunnel with the

holes in the lawn mower deck.

2. Fasten the rear-left and the rear-right corners of the

discharge tunnel to the lawn mower deck using two

capscrews, two flat washers, and two locknuts

previously removed.

3. Fasten the front-right side of the discharge tunnel to

the lawn mower deck using the 1/2 in. hex head

washer screw previously removed.

4. Fasten the front-left corner of the discharge tunnel and

the spring bracket to the lawn mower deck using the

3/4 in. hex head washer screw previously removed.

5. Install the new discharge door assembly and secure it

with the new door retainer.

6. Install the new latch plate to the discharge tunnel using

two new self-tapping screws.

7. Hook one end of the spring extension through the hole

on the spring bracket and the other end onto the

discharge door handle.

8. Open and close the discharge door to ensure that the

discharge tunnel door closes when you release the

handle.

Installing the New Engine

1. Carefully set the new engine onto the lawn mower

housing.

2. Install and tighten the three new engine screws

(Fig. 10). Torque the engine screws to 250 to 400 in-lb

(28 to

45 N

S

m).

For Self–propelled Models

3. Install a new engine drive pulley.

4. Install the belt onto the pulley.