To increase cable tension, loosen front cable jam

nut and tighten back cable jam nut (Fig. 41) until a force

of 3-5 lbs. is required to engage brake. Force to be

measured at lever knob. Do not over adjust, so brake

band drags.

Close cover and secure retainer.

+)63'

'37+%' 2#3- $3#-' %#$.'

3105 ,#/ 065

!

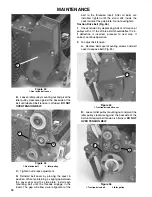

Use the following procedure should the switch need

adjustment or replacement.

Make sure the engine is OFF and traction lever is

DISENGAGED.

Loosen (2) switch mounting nuts (Fig. 43) and

move switch until switch plunger is depressed

.18

±

.06" (switch closed).

Tighten switch mounting nuts.

+)63'

05'3.1%- 48+5%*

1605+0) 0654

Engage traction lever and verify that the switch

plunger is depressed no more than .06" (switch open).

Readjust as required.

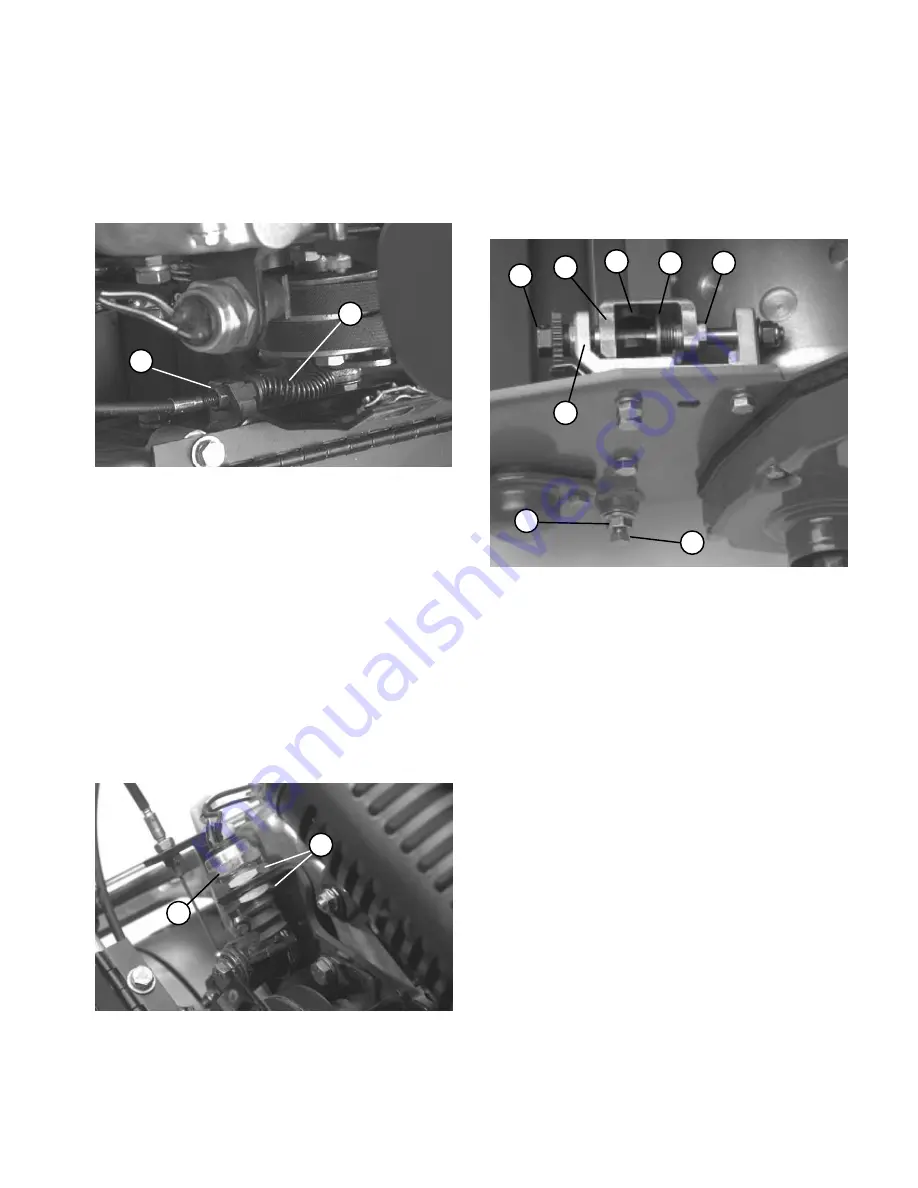

Turn bedbar adjuster screw, counterclockwise,

until channel bottoms out in adjuster frame (Fig. 44).

Using a 7/8" standard wrench, back out the spring

tension screw, until the trust washer is no longer

tensioned against the bedbar (Fig. 44).

'&$#3 #&,645+0) 4%3'8

23+0) 5'04+10 4%3'8

*3645 !#4*'3

'&$#3

+)63'

*#00'.

&,645'3 (3#/'

#/ 065

'&$#3 $1.5

On each side of the machine, loosen the jam nut

securing the bedbar bolt (Fig. 44).

Remove each bedbar bolt allowing bedbar to be

pulled downward and removed from machine.

Account for (2) nylon and (2) stamped steel washers

on each end of bedbar (Fig. 44).

"

Install bedbar, positioning mounting ears between

thrust washer and channel on bedbar adjuster.

Secure bedbar to each side plate with bedbar bolts

(flange nuts on bolts) and (8) washers. A nylon washer

is to be positioned on each side of side plate boss.

Place a steel washer outside each of the nylon

washers. Torque bolts to 240 Ć 320 inĆlb. Tighten flange

nuts until thrust washers just rotate freely.

Adjust bedbar, refer to Adjust Bedknife to Reel.

Remove plug in right reel drive cover (Fig. 45)

Insert a 1/2" socket extension, connected to back

lapping machine, into the square hole in the center of

reel pulley to backlap.

Backlap according to procedure in TORO

Sharpening Reel and Rotary Mowers Manual, Form

No. 80Ć300 PT.