Tighten nut to lock adjustment.

Reinstall belt cover by placing the cover in

position. While maintaining a slight gap between

the cover seal and the side plate, install each

mounting bolt until the threads engage in the

insert. The gap will allow visual alignment of the

bolt to the threaded insert. After all bolts are

installed, tighten until the stand offs inside the

cover contact the side plate. Do not overtighten.

'%%$-$*/' ( !$(/ '&

Check tension by depressing belt at mid span of

pulleys with 5

±

1 lbs. of force. Belt should deflect 1/4 in.

If deflection is incorrect, proceed to next step. If

correct, continue operation.

To adjust belt tension:

Remove capscrews securing front and rear

sections of differential cover to differential housing

and slide cover sections away to expose belt.

'&0-$

'%%$-$*/' ( !$(/

#($- ,0(($2

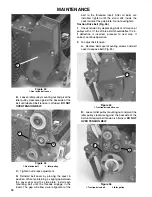

Loosen idler pulley mounting nut and pivot the

idler pulley clockwise against the backside of the

belt until desired belt tension is attained.

Tighten nut to lock adjustment.

Reinstall belt cover by placing the cover in

position. While maintaining a slight gap between

the cover seal and the side plate, install each

mounting bolt until the threads engage in the

insert. The gap will allow visual alignment of the

bolt to the threaded insert. After all bolts are

installed, tighten until the stand offs inside the

cover contact the side plate. Do not overtighten.

-') -2 !$(/. '&

To adjust belt tension on primary V - belts, first

check adjustment of traction control. Refer to Adjusting

Traction Control. If unable to attain the 3-5 lbs. force

required in adjusting traction control, proceed to next

step.

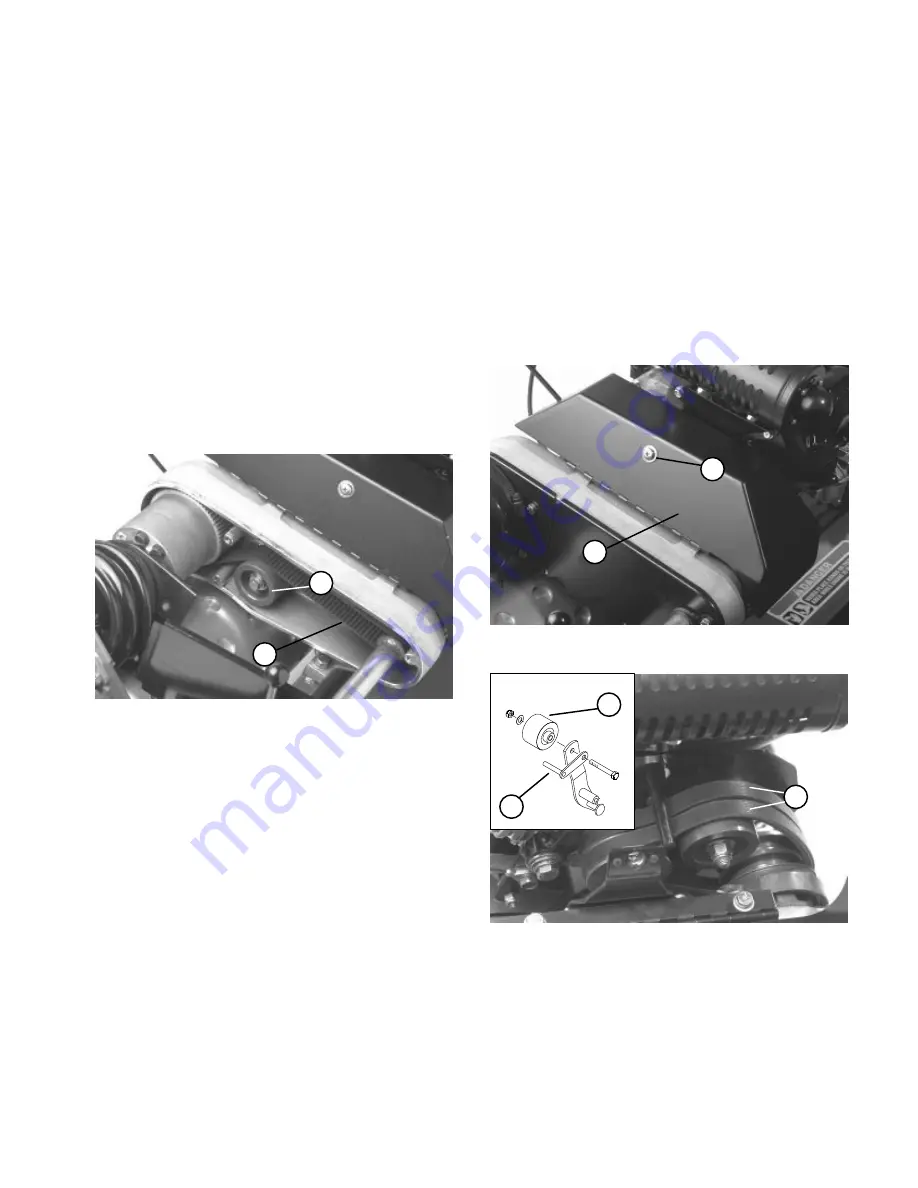

Loosen retainer securing V-belt cover and pivot

cover open.

To increase belt tension, loosen engine mounting

bolts and move engine backwards in slots.

Tighten mounting bolts.

+/$

The distance between the centers of the driver

and driven pulleys should be approximately 5.18" after

new V-belts are installed.

After tensioning primary V-belts, check alignment

of engine output shaft pulley and countershaft pulley

with a straight edge. If pulleys re misaligned, loosen

screws securing engine mounting base to mower

frame and slide engine from side to side until pulleys

are aligned within .030".

'&0-$

!$(/ "+1$-

$/ '*$-

'&0-$

-') -2 !$(/.

$(/ &0'#$

#($- ,0(($2

Tighten mounting screws and recheck alignment.

To push or pull machine easier without starting the

engine, adjust the belt guide (Fig. 39, inset) as follows:

Engage clutch.

Loosen capscrew securing idler pulley and

belt guide to idler arm.