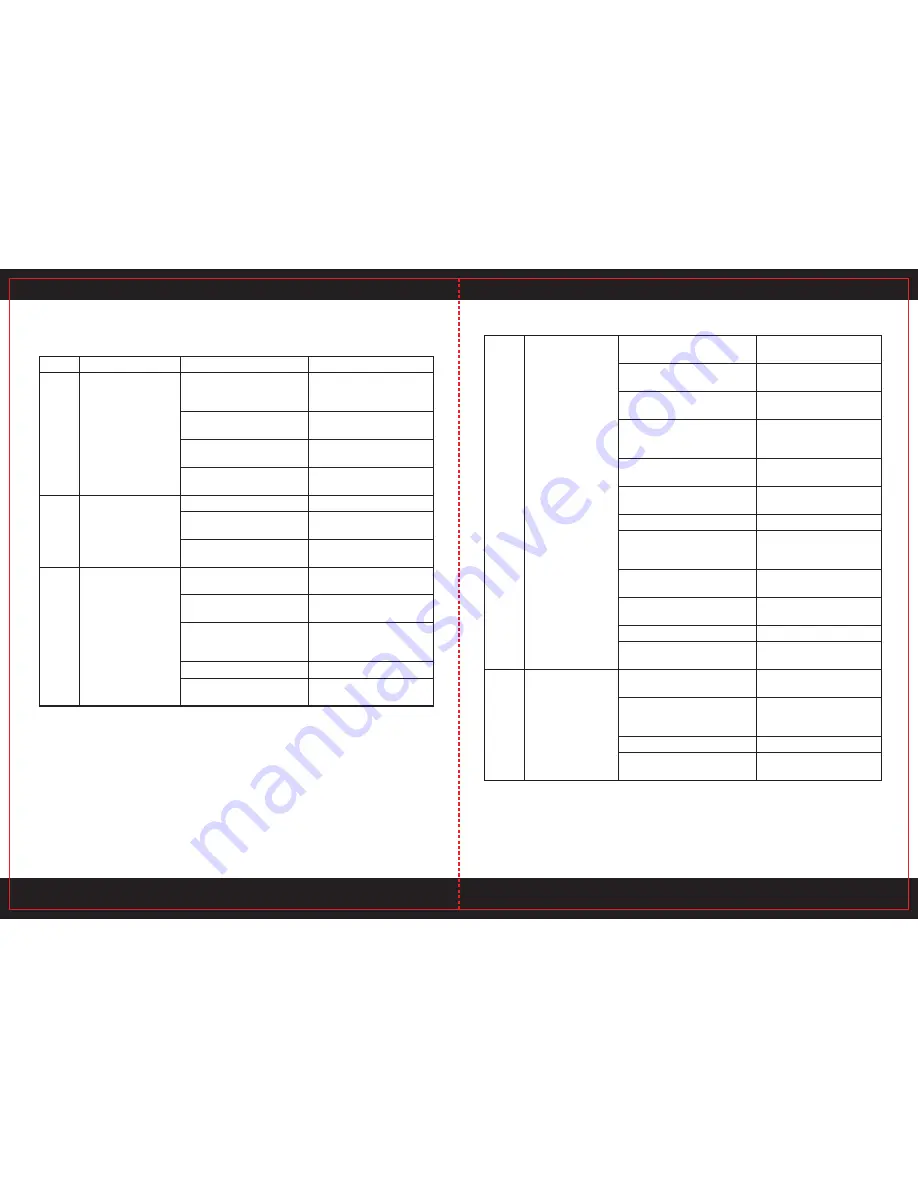

The Techniques Breakdown and Analysis

No.

Breakdown

Analysis

Solutions

1

Work piece is not cut

thoroughly

The cutting current is too

low

Adjust ‘Cutting thickness

Mode Switch’ to ‘Thick

Mode’

The cutting speed is too

rapid

Slow down the cutting

speed

Torch electrode or nozzle is

burn out

Replace electrode or noz-

zle

Cut thickness exceeds the

limit of the cutter

Replace with high-power

cutter

2

Slag drop out from

the Cutting Mouth of

Work Piece

Cutting Speed is too slow

Accelerate cutting speed

Cutting Electrode or Nozzle

is burnt

Replace electrode or noz-

zle

Cutting current is too high

Adjust cutting thickness

mode to ‘thin’ mode

3

Pilot is not stable

during operation

Compressed gas is too low

or too high

Adjust pressure

Electrode of cutting torch

or nozzle is burnt

Replace electrode or

nozzle

Connection between

cutting cable and work

piece is poor

Connect firmly

Cutting speed is too slow

Adjust speed

Input AC voltage is too low

Adjust power supply or

voltage

4

Cutting thickness is

not up to the rated

standard

Slag drop out from

the Cutting Mouth

of Work Piece

Pilot is not stable

during operation

Input compressed air pres-

sure is too low or too high

Adjust air pressure

Input compressed air flow is

too low

Adjust air flow

Cutting speed is too quick

Slow cutting speed

Material of work piece is not

symmetry with the thickness

standard

Adjust

Nozzle or electrode is burnt

Replace nozzle or elec-

trode

Nozzle type is not right

Replace with a suitable

nozzle

Cutting mouth is not vertical

Adjust cutting mouth angle

Gas leak from the gas circuit,

making the true cutting flow is

not enough

Examine and repair the

gas circuit

Input power supply is a bit

low

Adjust the power supply

Input or output lead is too

thin or pressure is too big

Widen down-lead

Cutting speed is too slow

Adjust speed

Input AC voltage is too low

Adjust power supply or

voltage

5

Cut is a bit declin-

ing

Nozzle or electrode is burnt

Replace nozzle or elec-

trode

The installation position of

nozzle and electrode is not at

the same axes

Install again correctively

Cutting speed is too high

Adjust cutting speed

Nozzle axes is not plumb with

the plane

Adjust the torch angle

17

18

Summary of Contents for POWER CUT 25K

Page 1: ......