11

BEFORE OPERATION

1.

Remove the cap of the exhaust port

△

!

WARNING;

In the case of a brand new winch, the cap is attached on the exhaust port when

shipped from the factory.(except TAW-300B)

Please remove this cap, otherwise, the winch will not operate.

Depending on conditions, this cap might blow off and lead to an accident.

2.

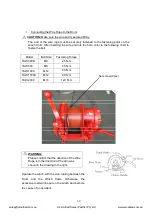

Turn clutch handle on

This air winch is equipped with a “Clutch” to link

the air motor and drum(ON) and to release the air motor

and drum(OFF).

This clutch is controlled by Clutch handle.

Please turn this handle ON as shown in the drawing to the

Right, this will connect the air motor and drum. In the

OFF position the air motor runs idle and drum will not

operate.

3.

Check Operation Air Pressure

△

!

CAUTION

; The operating air pressure is 0.4-0.6 MPa

If the air pressure is below 0.4MPa or exceeds 0.6MPa, this will effect the

performance, shorten the life of parts or will become a safety hazard. It is

necessary to keep good consideration concerning the pressure, volume and piping

for the compressor being used.

4.

Lubrication

△

!

CAUTION;

・

Lubrication to the motor is performed through the line oiler installed into the piping.

Oil flow to the motor should be 10-15 drops/min.

・

The reduction gears should be greased once every month using a grease gun.

When the gear box is dis-assemblied, the grease should be changed.

・

Apply lubrication to the wire rope. This should be performed periodically.

Clutch Handle

Lubrication Oil

Oil

Grade

Application

Lubricating method

Additive

Turbine oil

ISOVG32-46

Air motor part

Line oiler

Lithium grease

NLGINo.2

Rope, Gear

Apply to rope and gear case

Air & Allied Sales (Pacific) Pty Ltd

www.air-allied.com.au