Anti Rolling Gyro

Model:MSM-17500T-A1

-

23

-

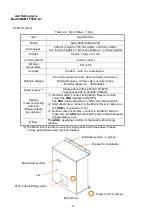

Table 5-2 Check sheet

Prepared by

Date:

Discrepancy Inquiry Sheet (form for users)

Control number:

1.

2.

Information on user

User name

Name of ship

Material and application of vessel

Material: iron, aluminum, GFRP, others ( )

Application:

Size of vessel

Overall length:

overall width:

displacement:

tons

3.

Number of units installed

Number of units showing discrepancy

Condition for operation

Duration in service:

Capacity of power generator

Single-phase

・

3-phase, 200

・

220

・

240V,

(

)KVA, (

)

A

4.

About what time was the last inspection?

About (Year)

(month)

YES

・

NO

・

Unknown

5.

6.

7.

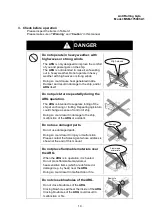

Start check lamp and/or rotation rate check lamp not illuminated

13.

~

17.

Operation not started even if switch is turned on.

13. 14. 16. 17.

Operation interrupted (impossible to restart)

8.

~

11.14.

~

17.

Noise increased (larger than in conventional operations)

8.

~

11.14.

~

17.

Vibration increased (larger than in conventional operration)

8.

~

11.14.

~

17.

Other abnormal conditions

9.10.15.

~

17.

8.

Is mounting to hull free from any loose bolt?

YES

・

NO

(

Conditions:

)

9.

Is damper free from any oil leaks? (Note that oil is transparent.)

YES

・

NO

(

Conditions:

)

10. What degree of temperature is indicated by thermo label attached to damper?

White: normal Other colors: 70

℃

80

℃

90

℃

11.

Abnormal noise

・

vibration

Occurred at: starting

・

a steady rate operation

・

all times

・

others

(

Conditions:

)

12.

ARG proper

・

motor driver

・

lamp

・

switch

・

others

(

Conditions:

)

13.

YES

・

NO

(

Conditions:

)

YES

・

NO

(

Conditions:

)

Is remote switch wiring free from any open-circuit?

YES

・

NO

(

Conditons:

)

Is system free from any blown lamp bulb?

YES

・

NO

(

Conditiions:

)

YES

・

NO

(

Conditions:

)

14.

15.

16.

17. Is ARG free from any accumulation of powder or dust?

YES

・

NO

(

Conditions:

)

8.

~

11.14.

~

17.

Mounting method and

operation of ARG

Date of last inspection

and inspection results Were there found any results related to the event of this time?

Time at or duration in

which you feel there is

some discrepancy,

and symptom making

you feel so

Describe differences in conditions of ARG before and after

discrepancy was revealed.

is Primary power available?

Is Power cable free from open-circuit?

is the Breaker on?

<E

xcept ARG175T

>

Is ARG connector free from loose contact?

(Is it latched properly when plug ring is turned?

)

Is motor driver fan in operation?

(Fan rotation sound heard?

)

Is grounding to hull in good condition?

Kind of

discrepanc

ies (Select

appropriat

e items

and

explain

conditions.

)

At a time of what have noises or vibrations occurred, at starting, at a steady rate

operation or at all times? How long did they last, for a certain period or continuously?

How is the noise heard? (What kinds of sound are generated?)

Kind of abnormal

odor

Examples: smell of burnt oil, smell offensive to eyes, smell of burnt

bakelite

What is source of oder?

Conditions

TYP

:

P/N

:

S/N

:

Mounting position of ARG showing discrepancy, and

peripheral devices

Anti-vibration rubber: provided

・

not provided

Mounting method

(directly or through anti-vibration rubber)

Please fill in the blanks after TYP, P/N and S/N with the appropriate

indications on the information plate of ARG.

Time at which you recognized discrepancy and duration in

which operation has been sustained after that

YES

・

NO

(

Conditions:

)

Operation has been sustained

・

stopped from

(year/month /day).

Abnormal noise generated

(not experienced in conventional operations)

Abnormal odor generated

(not experienced in conventional operations)

Approximate cumulative operation time or approximate period of operation

time

Hr

Describe operating conditions of ship before and after

discrepancy was revealed.

Large rolling caused by sharp turning, unexpected big wave,

sudden gust, etc. or changes in power supply conditions

resulted from installation of new auxiliary equipment, and so

on

Kind of discrepancies

Tick off

Answ er to questions in

follow ing items if

appropriate.

Approx.

℃

YES

・

NO

(

Conditions:

)

9.10.12. 15.

Findings from

electrical

system checks

Are starting and stopping performed in the same procedure as specified in Operation

Manual?

Has ARG been protected against splashes of sea water? (Is it free from any trace of

exposure?

)

What degree is the ambient temperature?

What is the atmospheric temperature in ARG installation place when ARG is in

operation?

YES

・

NO

(

Conditions:

)

YES

・

NO

(

Conditions:

)

Summary of Contents for ANTI ROLLING GYRO ARG175T

Page 33: ...Anti Rolling Gyro MSM 17500T A1 32 Anti Rolling Gyro ARG ARG...

Page 35: ...Anti Rolling Gyro MSM 17500T A1 34 ARG ARG ARG a b c ARG ARG ARG ARG ARG ARG ARG ARG...

Page 36: ...Anti Rolling Gyro MSM 17500T A1 35 1 1 1 ARG ARG...

Page 37: ...Anti Rolling Gyro MSM 17500T A1 36 1 2 ARG...

Page 38: ...Anti Rolling Gyro MSM 17500T A1 37 1 3 ARG ARG ARG ARG ARG ARG ARG 2 ARG ARG ARG ARG ARG...

Page 41: ...Anti Rolling Gyro MSM 17500T A1 40 3 3 1 ARG ARG ARG ARG ARG ARG ARG ARG ARG ARG ARG...

Page 43: ...Anti Rolling Gyro MSM 17500T A1 42 ARG 80 90 ARG ARG ARG ARG ARG ARG ARG 3 ARG 1 3...

Page 44: ...Anti Rolling Gyro MSM 17500T A1 43 ARG ARG ARG ARG ARG ARG ARG ARG ARG 3 ARG ARG 1 ARG 3...

Page 46: ...Anti Rolling Gyro MSM 17500T A1 45 3 1 ARG 2 3 No 8 9 10 11 12 4 13 14 15 ARG 16N m...

Page 51: ...Anti Rolling Gyro MSM 17500T A1 50 4 4 ARG ARG ARG ARG ON 4 3 5 5 1 No 5 4 3 No ARG 1 ON ON...

Page 55: ...Anti Rolling Gyro MSM 17500T A1 54 6 2 6 1 ARG 2 ARG ARG ARG ARG ARG ARG ARG...

Page 56: ...Anti Rolling Gyro MSM 17500T A1 55 ARG ARG ARG 2 ARG 2 3 ARG ARG 1 ARG 3...

Page 57: ...Anti Rolling Gyro MSM 17500T A1 56 6 1 ARG 1 4 No 1 ARG ARG 2 3 ARG 130N m 4 5 ARG 6 ARG 7...

Page 59: ...Anti Rolling Gyro MSM 17500T A1 58 6 1 ARG 3 4 No 15 ARG 16 N m 16 17 18 4 19 20...

Page 60: ...Anti Rolling Gyro MSM 17500T A1 59 6 1 ARG 4 4 No 21 22 ARG 23 ARG...