4

SAFETY PRECAUTIONS

IMPACT 540

1

SAFETY REGULATIONS FOR AIRLESS

SPRAYING

1.1

EXPLANATION OF SYMBOLS USED

This manual contains information that must be read and understood

before using the equipment. When you come to an area that has one

of the following symbols, pay particular attention and make certain to

heed the safeguard.

This symbol indicates a potential hazard that

may cause serious injury or loss of life. Important

safety information will follow.

Attention

This symbol indicates a potential hazard to you

or to the equipment. Important information that

tells how to prevent damage to the equipment

or how to avoid causes of minor injuries will

follow.

Danger of skin injection

Danger of fire from solvent and paint fumes

Danger of explosion from solvent, paint fumes

and incompatible materials

Danger of injury from inhalation of harmful

vapors

Danger of electric shock

i

Notes give important information which should

be given special attention.

1.2

GROUNDING INSTRUCTIONS

This product must be grounded. In the event of an electrical short

circuit, grounding reduces the risk of electric shock by providing an

escape wire for the electric current. This product is equipped with a

cord having a grounding wire with an appropriate grounding plug.

The plug must be plugged into an outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding

plug can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do not connect

the green grounding wire to either flat blade terminal. The wire with

insulation having a green outer surface with or without yellow stripes

is the grounding wire and must be connected to the grounding pin.

Check with a qualified electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt

as to whether the product is properly grounded. Do not modify the

plug provided. If the plug will not fit the outlet, have the proper outlet

installed by a qualified electrician.

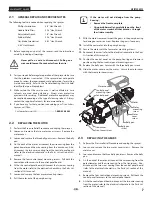

This product is for use on a nominal 120 volt circuit and has a grounding

plug that looks like the plug illustrated below. Make sure that the

product is connected to an outlet having the same configuration as

the plug. No adapter should be used with this product.

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

1.3

SAFETY HAZARDS

WARNING: INJECTION INJURY

A high pressure stream produced by this equipment

can pierce the skin and underlying tissues, leading to

serious injury and possible amputation.

Do not treat a spraying injury as a harmless cut. In

case of injury to the skin through coating materials or

solvents, consult a doctor immediately for quick and

expert treatment. Inform the doctor about the coating

material or solvent used.

PREVENTION:

•

Do not aim the gun at, or spray any person or animal.

•

Keep hands and other body parts away from the discharge. For

example, do not try to stop leaks with any part of the body.

•

NEVER put your hand in front of the gun. Gloves will not provide

protection against an injection injury.

•

ALWAYS keep the tip guard in place while spraying. The tip guard

provides some protection but is mainly a warning device.

•

Only use a nozzle tip specified by the manufacturer.

•

Use caution when cleaning and changing nozzle tips. In the case

where the nozzle tip clogs while spraying, ALWAYS lock gun

trigger, shut pump off, and release all pressure before servicing,

cleaning tip or guard, or changing tip. Pressure will not be released

by turning off the motor. The PRIME/SPRAY valve or pressure bleed

valve must be turned to their appropriate positions to relieve

system pressure. Refer to PRESSURE RELIEF PROCEDURE described

in the pump manual.

•

Do not leave the unit energized or under pressure while

unattended. When the unit is not in use, turn off the unit and relieve

the pressure in accordance with the manufacturer’s instructions.

•

High-pressure spray is able to inject toxins into the body and

cause serious bodily injury. In the event that injection occurs, seek

medical attention immediately.

•

Check hoses and parts for signs of damage, a leak can inject

material into the skin. Inspect hose before each use. Replace any

damaged hoses or parts. Only use TITAN original-high-pressure

hoses in order to ensure functionality, safety and durability.

•

This system is capable of producing 3300 PSI / 228 Bar. Only

use replacement parts or accessories that are specified by the