© Titan Tool Inc. All rights reserved.

21

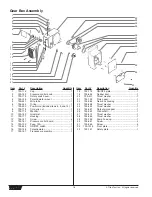

Servicing the Seat

The design of the fluid section allows access to the inlet and

outlet valves and seat without completely disassembling the

fluid section. It is possible that the valves may not seat

properly because of debris stuck in the inlet or outlet seat.

Follow the instructions below for access to those areas.

5. Place a wrench on the foot valve housing (21) and

unthread.

6. Clean out all debris. Examine the foot valve parts and the

inlet valve seat (19). If damaged replace. Continue if

necessary or re-install.

7. Place a 3/4" socket on the outlet valve housing (14) and

remove.

8. Clean out all debris. Examine the outlet valve parts and

the seat (12). If damaged, reverse or replace.

9. Reassemble and test the unit. Should the unit not

perform properly, consult the “Troubleshooting” section in

this manual or continue with the valve repair and packing

replacement instructions below.

Servicing/Replacing the Outlet Valve

10. To clean or replace the outlet valve, remove the outlet

valve housing (14) while piston assembly (22) is still

attached to pump. This will prevent the piston from

rotating.

11. Remove upper cage (10), the seat (9), and the outlet

valve ball (11). Clean and inspect along with the outlet

valve housing (14). Replace if worn or damaged. Use

fine sandpaper to remove dried paint.

12. Reattach items 9–14 to the piston rod (8), and secure

tightly with a wrench.

Replacing the Packings

13. Unscrew the hose (see the “Filter Block Assembly” parts

list) from the fitting.

14. Remove the screws (6) with a 3/8" hex wrench and slide

the fluid section down so that the piston rod (8) is clear to

slide off.

15. Inspect the polyethylene gasket on the fitting after

removing the fluid section. Clean or Replace.

16. Remove the retainer (2) and slide the piston rod down

through the pump housing (5) by lightly tapping on top of

piston assembly (22). Clean and inspect the piston rod

for wear. Replace if necessary.

17. Remove the upper packings (4) and the lower packings

(8) from the pump housing (5) and replace with a new set.

Always insert the packings with the raised side facing into

the pump housing.

18. Reattach the retainer (2) and make sure that the upper

guide (3) is clean and undamaged.

19. Place the pump housing (5) into a vise, leaving enough

room to slide the piston rod through the bottom of the

pump housing.

20. Using the piston guide tool (included in the repacking kit),

which slides over the top of the piston assembly (22),

insert the piston rod through the bottom of the pump

housing (5) and tap lightly with a rubber mallet on the

bottom of the piston rod until inserted.

21. Align the flats on the piston rod so that they are

perpendicular to the pump housing (5) and will line up

when reattaching to the connecting rod (1). This can be

achieved by rotating the piston rod by placing a wrench

on the outlet valve housing assembly (14) and turning.

Never use a wrench on the piston rod itself. This could

cause damage to the piston rod and cause leakage.

22. Slide the assembled pump housing with the piston

assembly onto the connecting rod and secure with the

screws (6). Be certain that the outlet hole is facing

towards the pump motor.

CAUTION

23. Reattach the hose (see the “Filter Block Assembly” parts

list) to the fitting. Be sure that polyethylene gasket is in

place.

24. Reattach the foot valve assembly (23).

26. Reattach the return tube and the siphon assembly.

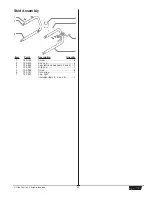

Siphon Assembly (P/N 700-1025)

Item

Part #

Description

Quantity

1

700-847

Return tube ......................................1

2

704-121

O-ring (standard) .............................2

704-109

O-ring, solvent-resistant (optional) ..2

3

704-127

Retaining clip ...................................1

4

700-1023

Siphon hose

(includes items 2, 3, and 6 ..............1

5

755-135

Clip...................................................1

6

700-805

Intake screen ...................................1

1

5

2

3

4

6

NOTE: Repacking Kit P/N 730-401 is available. For

best results use all parts supplied in this kit.

NOTE: Packing does not need to be adjusted.