Titan Implement, LLC

37

3515 Flex-Wing Rotary Cutter

(423) 334-0012

February 2020

6.6 Machine Break-In

Although there are no operational restrictions on

the rotary cutter when used for the first time, it is

recommended that the following mechanical items be

checked:

1. After 1/2 hour of operation:

a. Tighten all fasteners if necessary.

b.

Lubricate all grease fittings.

2. After 10 hours of operation:

a.

Go to the normal servicing and maintenance

schedule, as defined in the Maintenance

Section.

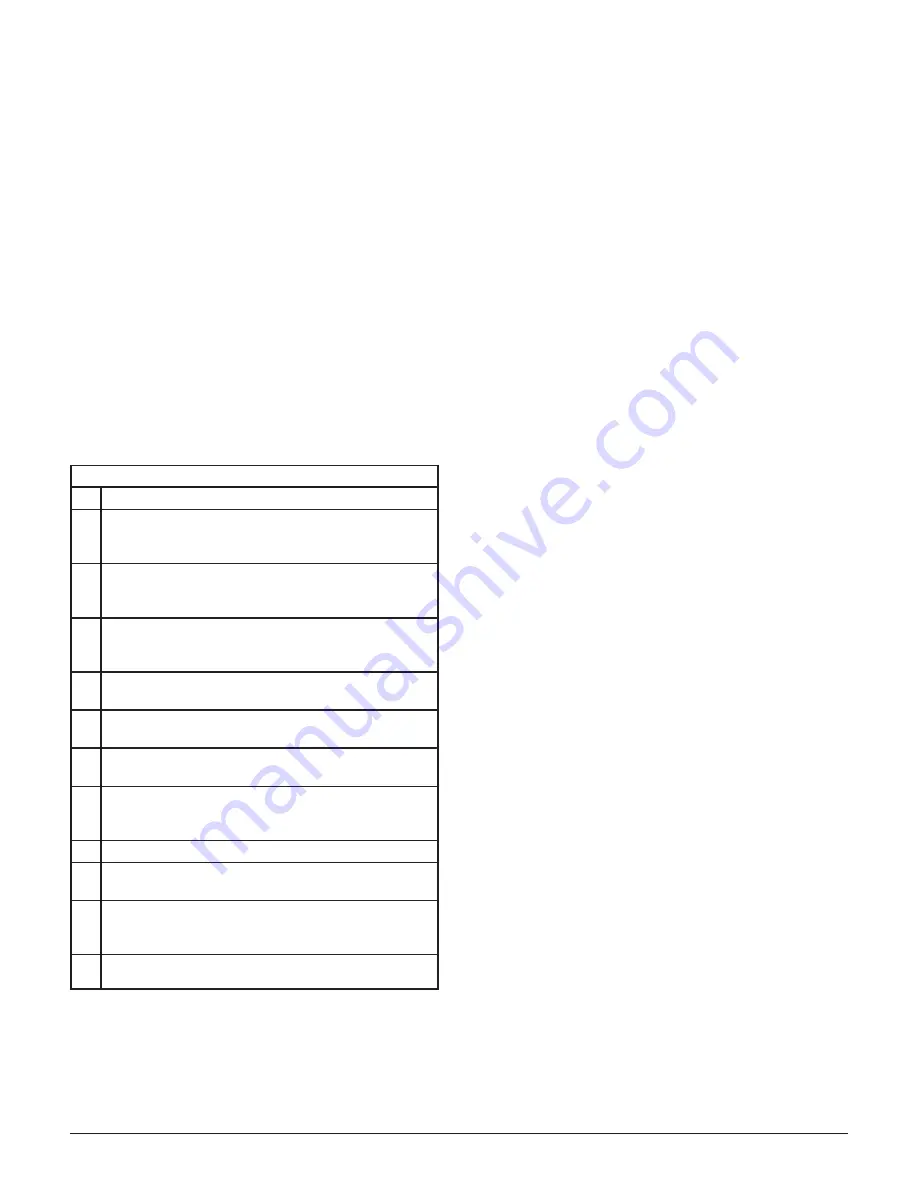

6.7 Pre-Operation Checklist

Before each use of the rotary cutter, the following areas

should be checked.

Checklist Before Each Use

4

Task

Make sure the rotary cutter is positively attached to

the tractor drawbar. Refer to “6.3 Attaching to Tractor”

on page 33.

Make sure the hydraulic hoses are undamaged, are

secured on the hose rack, and cannot contact the

tractor when turning or drag on the ground.

Use only an appropriately-sized tractor to pull the

rotary cutter. Refer to “6.2 Tractor Requirements” on

page 32.

Make sure the driveline is attached to the tractor PTO.

Refer to “6.3 Attaching to Tractor” on page 33.

Make sure all safety shields and guards are properly

installed.

Check the blade bolts and blade pan nuts. Refer to

“9.6 Blade Servicing” on page 47.

Inspect wing blade carriers and blades for locked

blades prior to lowering the wings. Use a pry bar or

other tool to separate locked blades.

Check the condition of the blades.

Check the cutting height. Adjust if needed. Refer to

“6.4.2 Setting the Cutting Height” on page 35.

Inspect the overall rotary cutter for potential problems

or damage. Do not use the rotary cutter if it needs

repairs of any type.

Make sure the driveline CV joint, U-joints, and slip joints are

greased. Refer to “9.5 Driveline Lubrication” on page 47.

6.8 General Operating Procedure

Although the rotary cutter is easy to use, each operator

should review this section to familiarize themselves

with the detailed safety and operating procedures.

1. Operate the rotary cutter only in conditions where

you have clear visibility in daylight or with adequate

artificial lighting. Never operate the rotary cutter

in darkness or foggy conditions where you cannot

clearly see at least 300 feet in front and to the sides

of the tractor and rotary cutter. Make sure that

you can clearly see and identify passersby, steep

slopes, ditches, drop-offs, overhead obstructions,

debris, and foreign objects. If you are unable

to clearly see these type of items, discontinue

operating the cutter.

2. Clear the area of bystanders, especially small

children.

3. Clear the area to be cut of stones, branches,

debris, and any hard objects that may be thrown.

Never operate the rotary cutter in an area that you

have not inspected and removed debris or foreign

material. Mark the location of objects that cannot be

removed.

4. Do not operate the rotary cutter, or drive the tractor

into material that is burning, or areas that recently

burnt and may contain hot spots. Burning material,

sparks, and coals could be thrown from the rotary

cutter to areas of vegetation that might ignite. Tire

damage can occur when driving over hot material.

Oil and grease on the tractor and rotary cutter

could ignite, resulting in equipment destruction.

Carry a fire extinguisher on the tractor at all times

to extinguish possible fires encountered. Do

not operate the rotary cutter on a tractor with an

underframe exhaust.

5. Raise the rotary cutter fully and remove the

transport lock. Fasten the transport lock around

a leveling rod to prevent its loss. Lower the rotary

cutter to operating height.

6. Remove the wing uplock pins and replace them in

the storage location. Lower the wings.

7. Engage the PTO at low engine RPM, then raise

PTO speed to 540 or 1000 RPM, as appropriate.

8. Begin cutting at a slow speed, then increase to a

speed that gives a clean cut without lugging the

engine. Do not operate above 5 MPH.

9. Never allow blades to contact solid objects like

rocks, posts, wire, curbs, guardrails, or the ground

while mowing.

Summary of Contents for 3515

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 55: ...Titan Implement LLC 55 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 59: ...Titan Implement LLC 59 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 61: ...Titan Implement LLC 61 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 63: ...Titan Implement LLC 63 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 65: ...Titan Implement LLC 65 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 76: ...3515 Flex Wing Rotary Cutter 76 Titan Implement LLC February 2020 423 334 0012 ...

Page 77: ...Titan Implement LLC 77 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...