Titan Implement, LLC

33

3515 Flex-Wing Rotary Cutter

(423) 334-0012

February 2020

6.2.4 Power Take-Off (PTO)

This rotary cutter is available in versions to operate at

a PTO speed of 540 RPM or 1000 RPM. Most tractors

operate at either 540 or a combination of 540 and 1000

RPM PTO speeds. The operating speed of the rotary

cutter and tractor can be determined by the number

of splines on the driveline yoke and PTO output shaft.

Those operating at 540 RPM will have a 6-spline shaft,

and those operating at 1000 RPM will have a 20 or

21-spline shaft.

Refer to the tractor Operator’s Manual for instructions

to change PTO speeds on models that operate at more

than one speed.

If operating an older model tractor where the tractor’s

transmission and PTO utilize one master clutch, an

over-running clutch must be used between the PTO

output shaft and the driveline of the rotary cutter. An

authorized tractor dealer can provide the over-running

clutch and its installation, if needed.

DO NOT use a PTO adapter to attach a non-

matching implement driveline to a tractor PTO. Use

of an adapter can double the operating speed of the

implement, resulting in excessive vibration, thrown

objects, and blade and implement failure. Adapter

use will also change the working length of the driveline

exposing unshielded driveline areas. Serious bodily

injury and/or equipment failure can result from using

a PTO adapter. Consult an authorized dealer for

assistance if the implement driveline does not match

the tractor PTO.

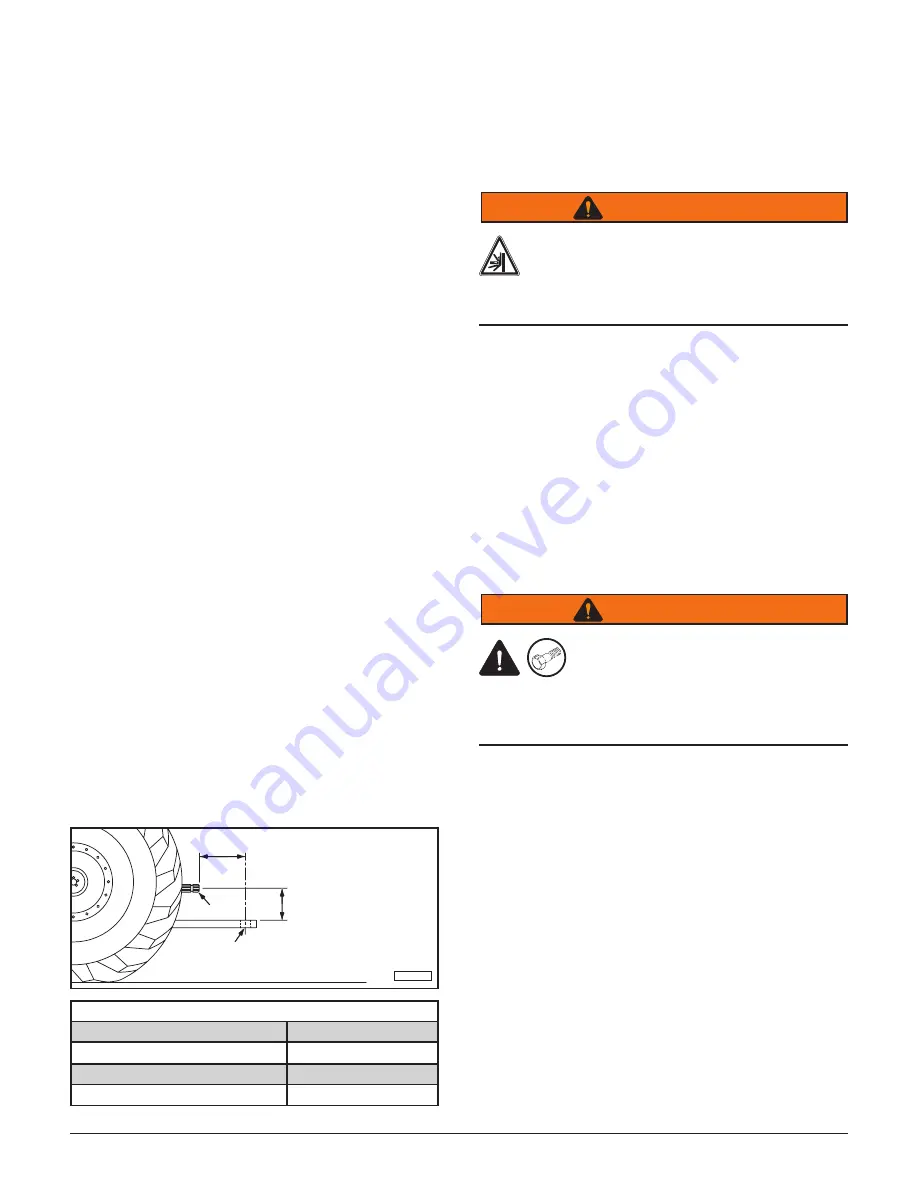

6.2.5 Drawbar

The distance between the drawbar hitch pin hole and

the end of tractor PTO shaft must be set according to

the PTO operating speed. The distance from the top of

the drawbar to the PTO shaft must be 8”. PTO damage

may occur if these dimensions vary more than 1”.

TI-00177

A

8”

Tractor PTO

Drawbar

Ground Level

DRAWBAR LENGTH CHART

PTO

Dimension A

540 RPM

14”

1000 RPM, 21 spline, 1-3/8” shaft

16”

1000 RPM, 20 spline, 1-3/4” shaft

20”

6.3 Attaching to Tractor

Use caution when connecting the rotary cutter to the

tractor. The rotary cutter should be securely resting at

ground level or setting on blocks. Keep hands and feet

from under the deck and clear of pinch points between

the tractor drawbar and rotary cutter hitch.

WARNING

Crush Hazard

Crush hazard between hitch and implement.

Do not allow anyone to stand between the

hitch and implement during hook-up

operations.

1. Use the jack to adjust the hitch to the height of the

tractor drawbar.

2. Board the tractor and start the engine. Back the

tractor up to the cutter hitch until the holes in the

drawbar and clevis are aligned.

3.

Turn off the tractor engine and dismount.

4. Insert a 3/4” or larger high strength drawbar pin

through the clevis and drawbar holes and install

retaining pin. Do not use a homemade or shop

made pin.

WARNING

OEM

Crush Hazard

Unexpected separation of the cutter

from the tractor can cause death or

serious injury. Use only an OEM high strength

drawbar pin. Do not use a homemade or shop made

pin.

5. Connect the hitch safety chain to the tractor drawbar

cage.

6. Retract the jack, remove the locking pin, move the

jack to its storage location on the cutter deck, and

secure it with the locking pin.

7. Pull back on collar (1) on the tractor end of the

driveline.

Summary of Contents for 3515

Page 1: ......

Page 2: ......

Page 4: ......

Page 6: ......

Page 55: ...Titan Implement LLC 55 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 59: ...Titan Implement LLC 59 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 61: ...Titan Implement LLC 61 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 63: ...Titan Implement LLC 63 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 65: ...Titan Implement LLC 65 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...

Page 76: ...3515 Flex Wing Rotary Cutter 76 Titan Implement LLC February 2020 423 334 0012 ...

Page 77: ...Titan Implement LLC 77 3515 Flex Wing Rotary Cutter 423 334 0012 February 2020 ...