3.

TINKERINE

STUDIO

STUDIO

[email protected] | 1-604-288-8778

70

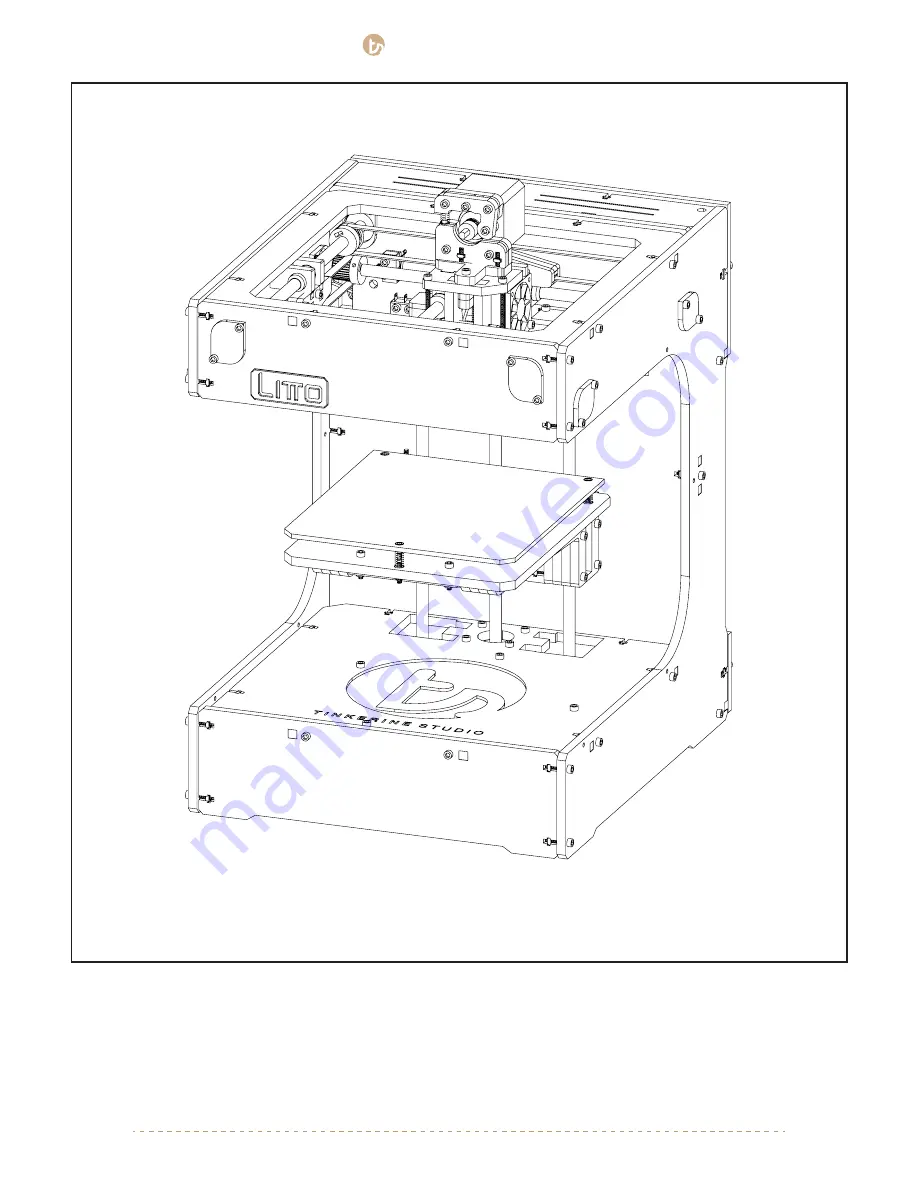

You’ve finished assembly your very own 3D printer (well almost!). With all of the components in the printer, move

on to the next step to begging the wiring portion of the assembly.

3.

TINKERINE

STUDIO

STUDIO

[email protected] | 1-604-288-8778

70

You’ve finished assembly your very own 3D printer (well almost!). With all of the components in the printer, move

on to the next step to begging the wiring portion of the assembly.