NOTE:

The Sheave Pac assembly installation tooling shall be

manufactured as a disk/plate to allow a complete 360 degree

contact between the tool and the assembly for a uniform load

distribution during installation into the sheave bore. It is suggested

that the installation plate be hardened material to minimize

handling/storage damage.

NOTE:

Prior to use, ensure that the installation plate is in acceptable

dimensional condition and free of sharp corners, raised

material, dents, nicks, burrs, gouges, and corrosion. Any surface

imperfections should be carefully filed and/or stoned down

completely prior to use. These imperfections may cause damage to

the seal during assembly installation.

Step 9

With the bearing and seal installation initiated manually to engage the

metal-to-metal contact between the cup and the sheave, carefully

ensure that the sheave/bearing is centered under the press ram.

Step 10

Gradually inch the press ram down until it gently comes into contact with

the installation tooling without creating an impact load on the system.

Step 11

With the press ram resting on the installation tooling, gradually

increase the applied load to continue the installation of the Sheave

Pac assembly into the sheave bore until clearance is available to

install the top snap ring behind the assembly.

Step 12

With the bearing assembly installed, remove the load from the press

and remove the installation tooling.

Step 13

Install the snap rings into the sheave.

NOTE:

Limited space is available around the seal for snap ring installation.

Care must be taken to ensure seal damage is

not incurred during this snap ring installation procedure.

Step 14

Repeat Steps 1-13 as necessary for additional sheaves for a complete

block build.

B. Mounting of the Bearing/Sheave onto Pin

General Installation Information

A. Required Equipment:

• Crane/hoist and lifting/handling fixture designed to safely

handle sheaves containing a Sheave Pac assembly.

NOTE:

The Sheave Pac assembly must remain carefully aligned with the

sheave bore throughout this step in order to decrease the

potential for seal O.D. damage.

NOTE:

Before moving to the next step, ensure that the cup is completely

engaged with the sheave, as shown in Figure 2.

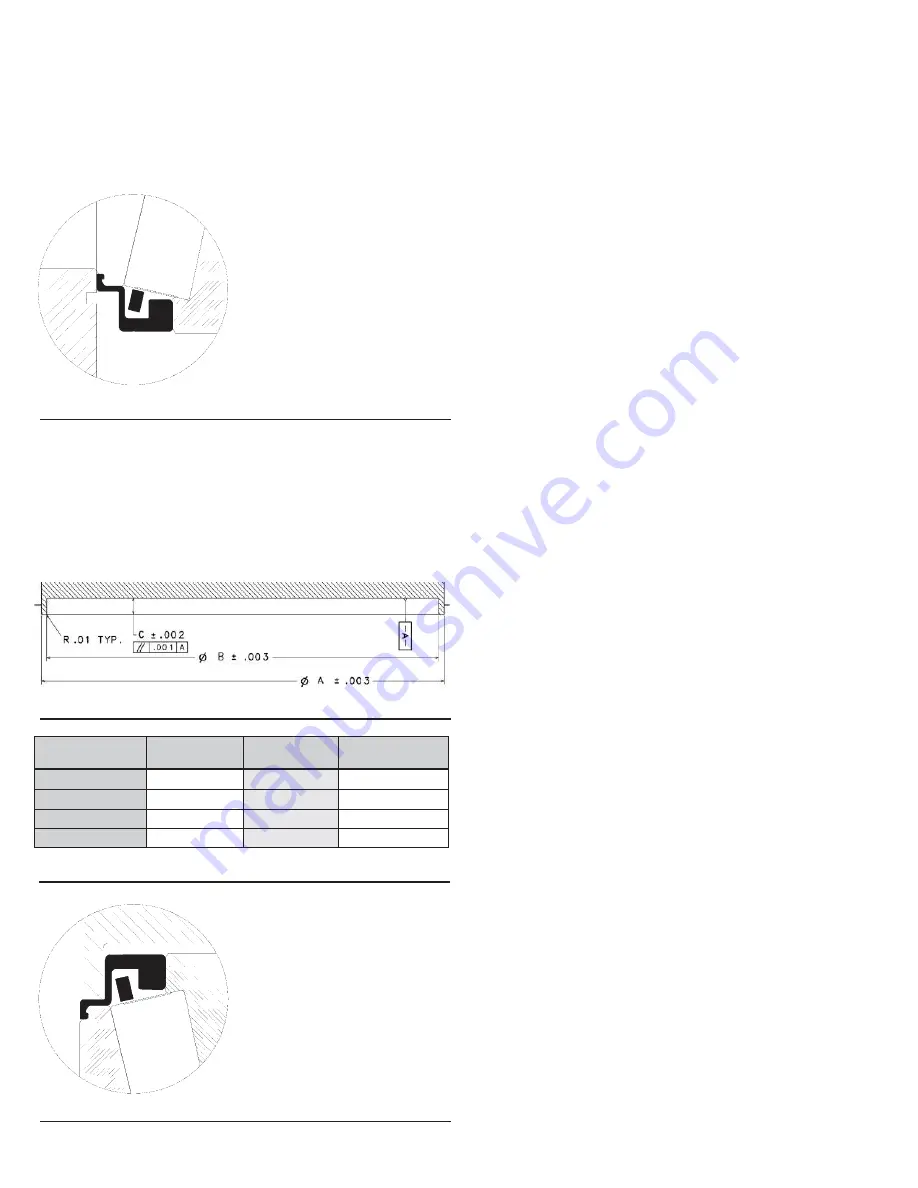

Step 8

With the bearing assembly carefully centered and started into the

sheave bore entrance, carefully place size-specific installation tooling

(manufactured to meet the surrounding seal dimensional requirements

shown in Fig. 3, Fig. 4, and Fig. 5) on the top side of cup/seal interface

so as not to damage/displace seal components.

Fig. 2

Fig. 5

Assembly Bore

A (+/-0.003 in.)

B (+/- 0.003)

C (+/- 0.00 2 in.)

8 in.

10.775

10.550

0.500

10 in.

13.588

13.200

0.750

12 in.

15.400

15.000

0.610

14 in.

17.400

17.000

0.625

5

Fig. 3

Fig. 4