18

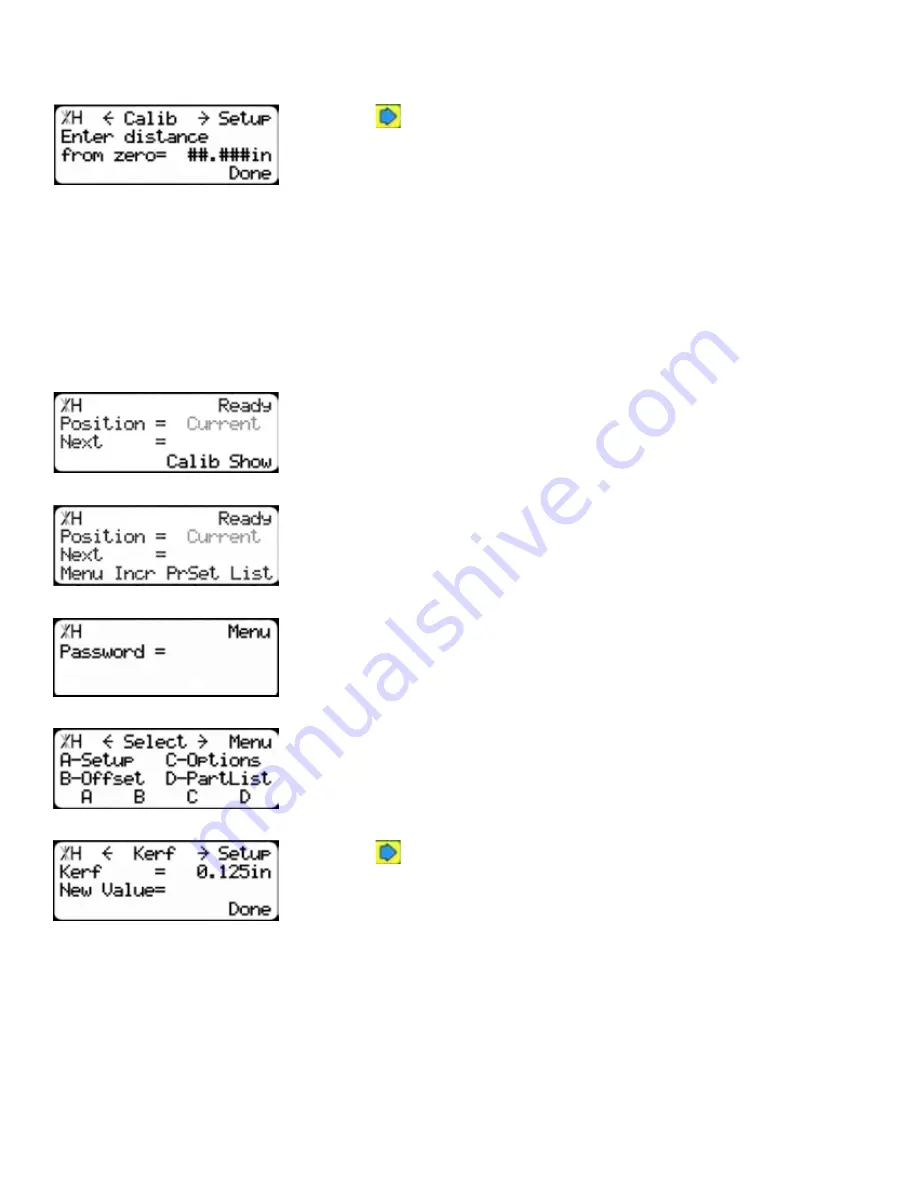

2. Measure how far the TigerRack is from your tool’s zero point.

3. Enter this measurement and press the [Done] soft key.

Note: TigerRack has been calibrated and you will be taken back to the Ready Screen.

Calibrate TigerRack

1. Press

to scroll through the settings until you get to the Calib

setting.

Set Kerf

If you have installed TigerRack on a cutting tool, you will need to set the kerf setting. The kerf is the

measure of how much material is destroyed by the saw blade during a cut.

1. From the Ready Screen, press the [Show] soft key to show the menu

options.

2. Press the [Menu] soft key to display the Menu Select screen.

3. TigerRack requires a password to access all menu options. Enter

your password and press [=].

Note: By default, the TigerRack password is set to the serial number.

4. At the Menu Select screen, press the [Setup] soft key to access the

Setup menu.

5. Press

to scroll through the settings. Stop when you get to the

Kerf setting.

To measure kerf...

1. Cut a sample piece and measure it with a caliper. Record your measurement.

2. Cut this piece in half.

3. Put the two pieces together as if they were one piece and re-measure with a caliper.

4. The difference between the measurement on step 1 and the measurement on step 3 will be your kerf

value.

5. Enter your kerf value and press the [Done] soft key to save the parameter.

Note: It is important to check and reset the kerf every time the saw blade is changed.