S C H E D U L E D M A I N T E N A N C E

5-4

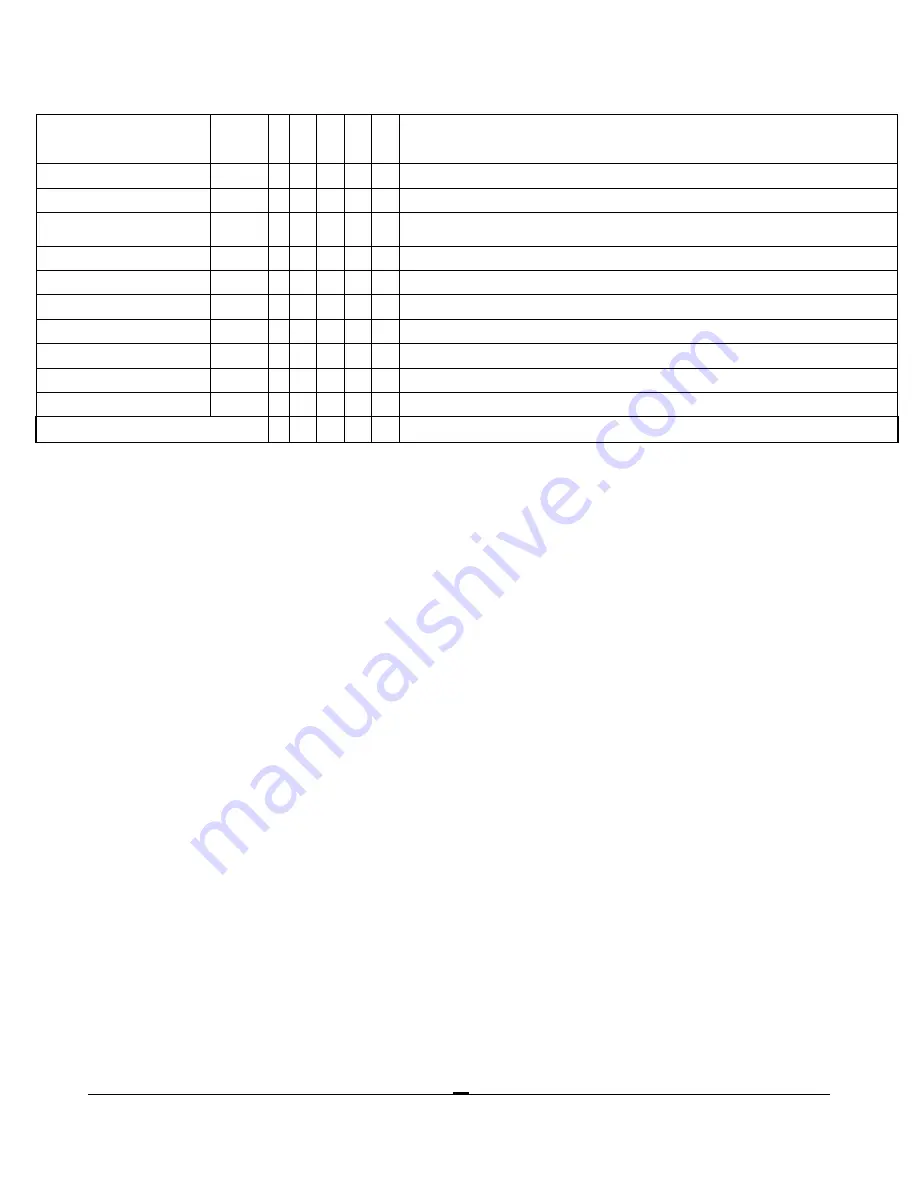

SERVICE INTERVAL

(Miles x 1,000)

Annually 5 10 15 20 50

Required Fluids, Lubricants, and Procedures

Suspension & Axles:

Automatic Slack Adjusters

X

Lubricate W/NGLI #2 grease (1)

Slack Adjuster Cam Shafts

X

Lubricate W/NGLI #2 grease (1)

Slack Adjuster Clevis Pins

X

Inspect for wear in clevis pin and cotter pins. Replace as necessary

Transmission & Driveline:

Drive Shaft

X

Inspect u- for loose bolts & wear, lubricate w/NGLI #2 grease (1)

Transmission Fluid

Replace fluid every 5 years or when indicated by transmission shift pad (5)

Transmission Filters

Replace filters every 5 years or when indicated by transmission shift pad (5)

(1) Replace / inspect at stated mileage interval or every 12 months, whichever occurs first.

(2) Re-torque all wheel nuts after the first 100 miles, then every 10K miles thereafter.

(3) Factory filled with synthetic oil. Do not mix with mineral oils. Change fluid every 3 years or 50K miles.

(4) For best tire life and handling, alignment of front axle is recommended every 15K miles.

(5) Factory filled with Allison approved TES-295 fluid. To maintain these service intervals, fluid must not be mixed with

Dexron or other fluids.

(6) Total fluid capacity is 24oz. Use only synthetic 75W90 oil. Change every 3 years or 50K miles.

(7) Replace filter when indicator shows 25 inches or every 12 months, whichever occurs first.

(8) Replace desiccant cartridge every 36 months.

(9) Change fluid every 5 years or 50K miles.

(10) Factory filled with 80W90 mineral oil. Do not mix with synthetic. Change fluid every 3 years or 50K miles.

(11) Drain, flush, and refill with new antifreeze/coolant every 5 years. Only use coolants that meet or exceed Cummins

requirements. Refer to appropriate Cummins literature for specifications. 2009 - 2016 model year coaches were factory filled

with Shell Rotella ELC. 2017 models were factory filled with Old World Final Charge Global.

(12) Vehicles with RL80 front suspensions require no hub maintenance for 600,000 miles. Vehicles with RL67, and RL77

front axles require no hub maintenance for 300,000 miles.

Summary of Contents for PowerGlide 2019

Page 6: ...T I R E C A R E 1 1 TIRE CARE Chapter 1 ...

Page 14: ...B R A K E S Y S T E M 3 1 Brake System Chapter 3 ...

Page 17: ...B R A K E S Y S T E M 3 4 Compressed Air System 36 and 40 Bus Non Tag Tank Drains ...

Page 18: ...B R A K E S Y S T E M 3 5 43 Bus Tag Tank Drains ...

Page 21: ...B R A K E S Y S T E M 3 8 ...

Page 37: ...C U M M I N S E N G I N E S 4 17 ...

Page 38: ...S C H E D U L E D M A I N T E N A N C E 5 1 Scheduled Maintenance Chapter 5 ...

Page 45: ...S C H E D U L E D M A I N T E N A N C E 5 8 Lubrication Points ...

Page 46: ...S C H E D U L E D M A I N T E N A N C E 5 9 Lubrication Points ...

Page 47: ...S C H E D U L E D M A I N T E N A N C E 5 10 Lubrication Points ...

Page 48: ...S C H E D U L E D M A I N T E N A N C E 5 11 Lubrication Points ...

Page 53: ...S C H E D U L E D M A I N T E N A N C E 5 16 ...

Page 54: ...P R E T R I P I N S P E C T I O N 6 1 Pre Trip Inspection Chapter 6 ...

Page 57: ...I N S T R U M E N T S C O N T R O L S 7 1 Instruments Controls Chapter 7 ...

Page 84: ...I N S T R U M E N T S C O N T R O L S 7 28 MENU MAP SETTINGS MENUS Settings Menus ...

Page 92: ...I N S T R U M E N T S C O N T R O L S 7 36 ...

Page 93: ...A I R S U P P L Y 8 1 Air Supply Chapter 8 ...

Page 95: ...A I R S U P P L Y 8 3 ...

Page 96: ...T A G A X L E 9 1 Tag Axle Chapter 9 ...

Page 98: ...W A R R A N T Y 10 1 Warranty Chapter 10 ...

Page 100: ...W A R R A N T Y 10 3 ...