WING

PREASSEMBLY

PRE-ASSEMBLY NOTES

1. If you are not an experienced R/C pilot, plan to have a

fully competent pilot check your completed model and

help you with your first flights. Even though we have tried

to provide you with a very thorough instruction manual,

R/C models are rather complicated and an experienced

modeler can quickly check over your model to make sure

your first flights are successful.

2. Please assemble your model exactly according to these

instructions. Do not attempt to modify or change the

Tiger

Trainer

in any way as doing so may adversely change

its flying characteristics.

3. Before you begin, please check the entire contents of

this kit against the parts drawing make sure that no parts

are missing or damaged. This will also help you to

become familiar with each component of your plane. If

you find that any of the parts are either missing or

damaged, please contact your dealer immediately for

replacement.

Note: Your dealer cannot accept kits for return if

construction has begun.

4. Trial fit each part before gluing it in place. Make sure

you are using the correct part and that it fits well before

assembling. No amount of glue can make up for a poor

fitting part.

WING ASSEMBLY

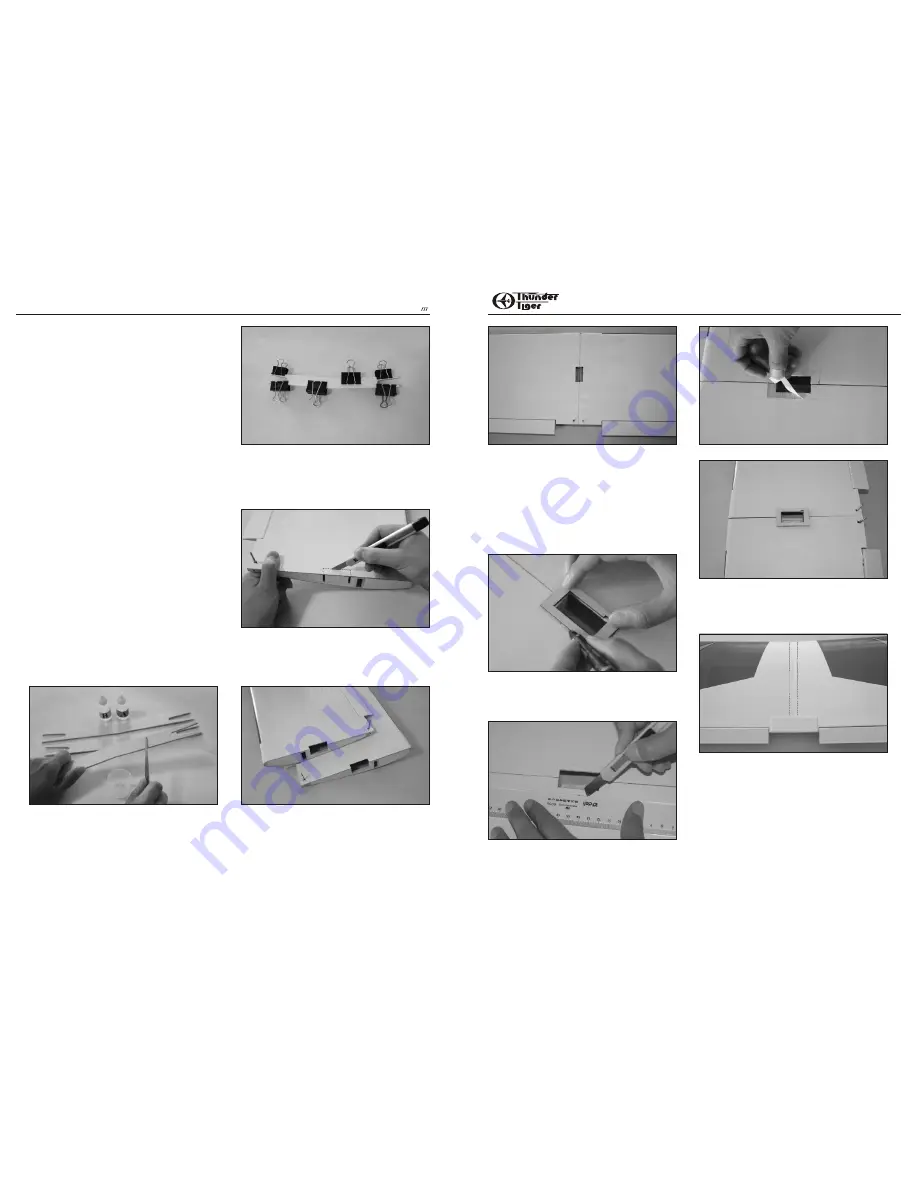

2. Clamp the three joiners together with clothes-pins or

other small clamps and wipe off the excess epoxy before

it cures. Allow the epoxy to cure before removing the

clamps.

3.On the bottom of one wing half, make a mark 3/8''

(10mm) from the inside edge of the wing, between the

pre-cut slot in the center rib and the rear edge of the spar

box. Use a hobby knife to cut away the covering and

balsa sheeting in this area.

7

6

1. Open the small wood parts bag and remove the three

1/8'' plywood wing panel joiners. Gently sand the edges

to remove any rough edges.

Mix up some 5-minute epoxy and apply it to both sides of

one of the joiners. Sandwich this piece between the

other two joiners, sand align the edges of all three

joiners.

4. Also remove the portion of center wing rib in this area

to allow clearance for aileron servo. Repeat the same

process on the other wing half.

Before gluing the two wing halves, trial-fit the wing

joiner into the wing panels. If it is not easy to slide into

the wing, sand it until it will. To fit properly, note that the

wing has an upward “bend ” in it: this is called dihedral.

5. With 30-minute epoxy, liberally coat all sides and

edge of the wing joiner and slip it into one wing half.

Now coat the inside edge of the center wing rib where it

will join to the other wing half. This is called the “root” of

the wing.

Join the two wing halves and firmly press wing panels

together. Wipe off any excess epoxy with a paper towel

and rubbing alcohol. Make sure the two panels are

accurately aligned with each other. You may hold

together with several strips of masking tape.

6. Place the servo tray centered over the cutout in the

bottom of the wing. Mark around the servo tray with a

pencil.

7. Remove the tray, and use a sharp knife to score the

covering material where marked. Remove the covering

material to expose the wood underneath. Use thick CA

or epoxy to glue the servo tray securely in place.

8. Locate the white trim tape and apply to center wing

joint. Start at the servo tray and work around the wing.

Gently pull on the tape while pressing it down onto the

wing to slightly stretch the tape into place and provide a

smooth seam.

Lightly sand the edges and one side of the plastic wing

protector to remove any roughness and help the glue

stick to the plastic. Use thick CA or epoxy to glue the

wing protector to the top surface of the wing so it is

centered over the wing joint and flush with the wing

trailing edge.

Tiger Trainer

MK