Rev B Sept 2020

Page 33

Chapter 5 PC Operation - Tutorial

7) In the slave NanoTrak GUI, select ‘Settings’.

8) Select the ‘Tracking’ tab, then set the Circle User Frequency, e.g. 30 Hz.

9) Select the ‘Input/Output’ tab, then set the Input Signal Source to ‘2 V SMA’.

10)Set both NanoTraks to ‘Track’.

11)Once alignment is achieved, tracking can be verified. Move the axes of the stage(s) by a small amount. The circle of the

NanoTrak associated with the stage should move accordingly to follow the signal.

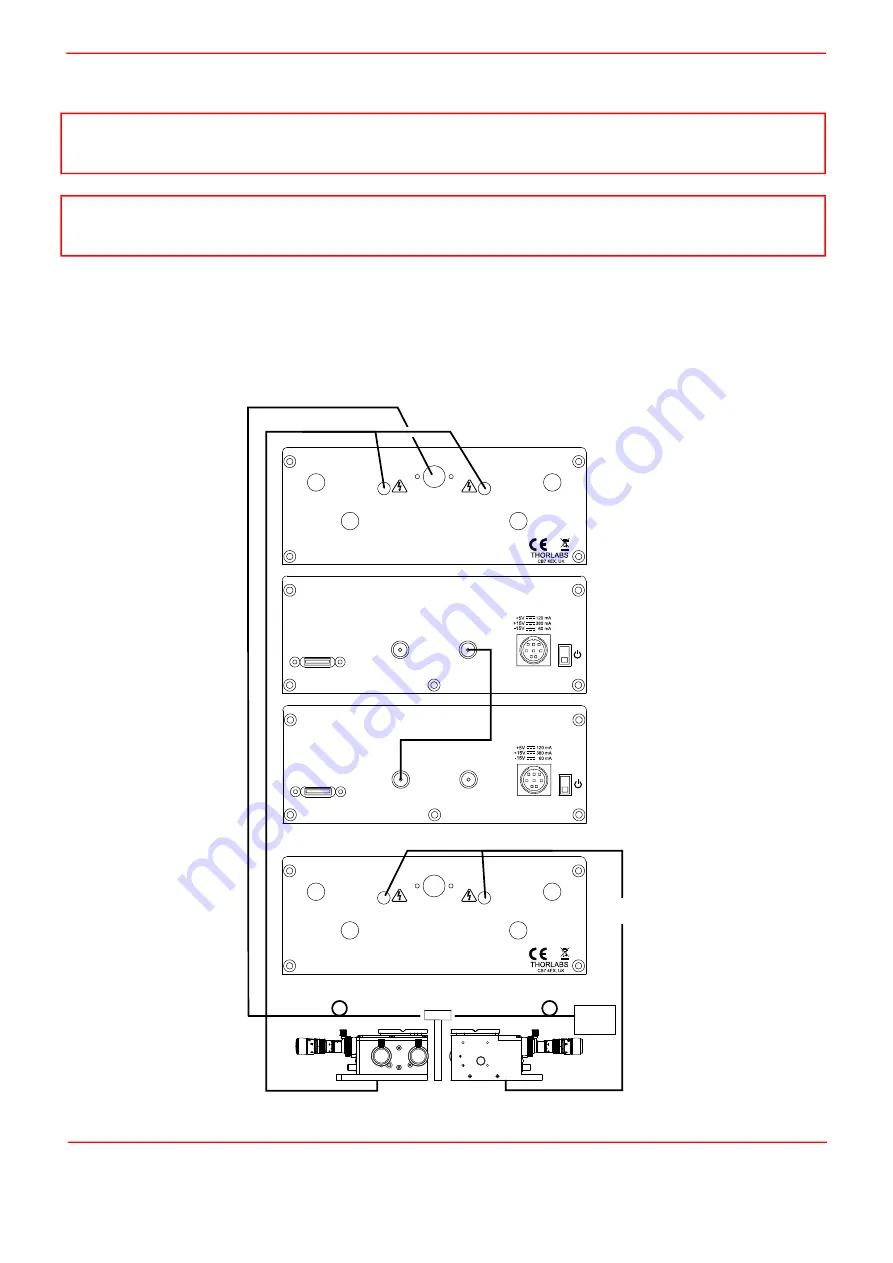

If using the internal power meter, the detector output is connected to the OPTICAL INPUT connector on the master unit and

the signal to the slave NanoTrak must be routed from the master I/O 2 to the slave I/O 1. If using an external power meter, this

is connected to I/O 1 on the master unit.

Fig. 5.7 Dual NanoTrak connections

Note

A difference of at least 10 Hz is recommended between this frequency and that set at item (5). This is to ensure adequate

frequency separation between the bandpass filters of the two NanoTraks.

Note

With SMA input source selected, the internal TIA circuit is bypassed and therefore autoranging is not required. Also, the

Tracking Indicator on the GUI panel is inoperative.

laser

source

input fiber

output fiber

waveguide

O/P piezo drive connections

Optical Input

I/P piezo drive connections

MONITOR 1

OPTICAL INPUT

MONITOR 2

HV

OUT 1

0 - 150V

HV

OUT 2

0 - 150V

EXT

IN 1

0 - 10V

EXT

IN 2

0 - 10V

900 - 1700 nm 1.5 mW

MONITOR 1

OPTICAL INPUT

MONITOR 2

HV

OUT 1

0 - 150V

HV

OUT 2

0 - 150V

EXT

IN 1

0 - 10V

EXT

IN 2

0 - 10V

900 - 1700 nm 1.5 mW

KNA-IR

USB

I/O 1

I/O 2

+5V TTL

+5V TTL

ON

KNA-IR

USB

I/O 1

I/O 2

+5V TTL

+5V TTL

ON

Output NanoTrak

Rear Panel

Output NanoTrak

Front Panel

Intput NanoTrak

Front Panel

Intput NanoTrak

Rear Panel

Summary of Contents for NanoTrak KNA-IR

Page 47: ...www thorlabs com ...