2-31

2

DRIVE MOTOR 2.12

Removal

1

Remove any attachment, raise the boom arms and

engage the boom support pins.

2

Raise the loader securely off the ground.

3

Remove the wheels on the side to be repaired.

4

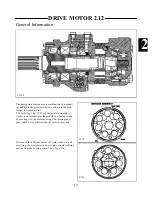

Drain the oil from the final drive housing. Be pre-

pared to contain approximately 1.9 gal (7 l) of fluid. (fig.

C1888)

5

Remove the seat and hydrostatic shield.

6

Remove the final drive inspection cover located

between the axles of the final drive housing.(fig. C2073)

7

Disconnect the chain as outlined in Section 3.

C1888

Oil drain plug

Upper fill check

C2073

Inspection cover

C2082

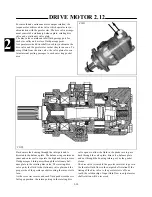

Brake hose

C2074

Hi - pressure hoses

9

Disconnect the brake line hose and the case drain

hose from the drive motor. Cap the hoses and adapter fit-

tings in the drive motor. (fig. C2082)

10 Remove the adapter fittings from the drive motor.

Plug the open ports in the drive motor to prevent contam -

ination.

8

Remove the 2 high pressure hoses from the drive

motor. ( fig. C2074 ) Cap the open hose ends and fittings

to prevent contamination.

WARNING

To prevent personal injury do not work under the

boom arms without the boom supports engaged.

When making repairs to the hydraulic system, keep

the work area and parts clean. Use caps and plugs

on all open line and ports.

IMPORTANT

Case drain hose