13

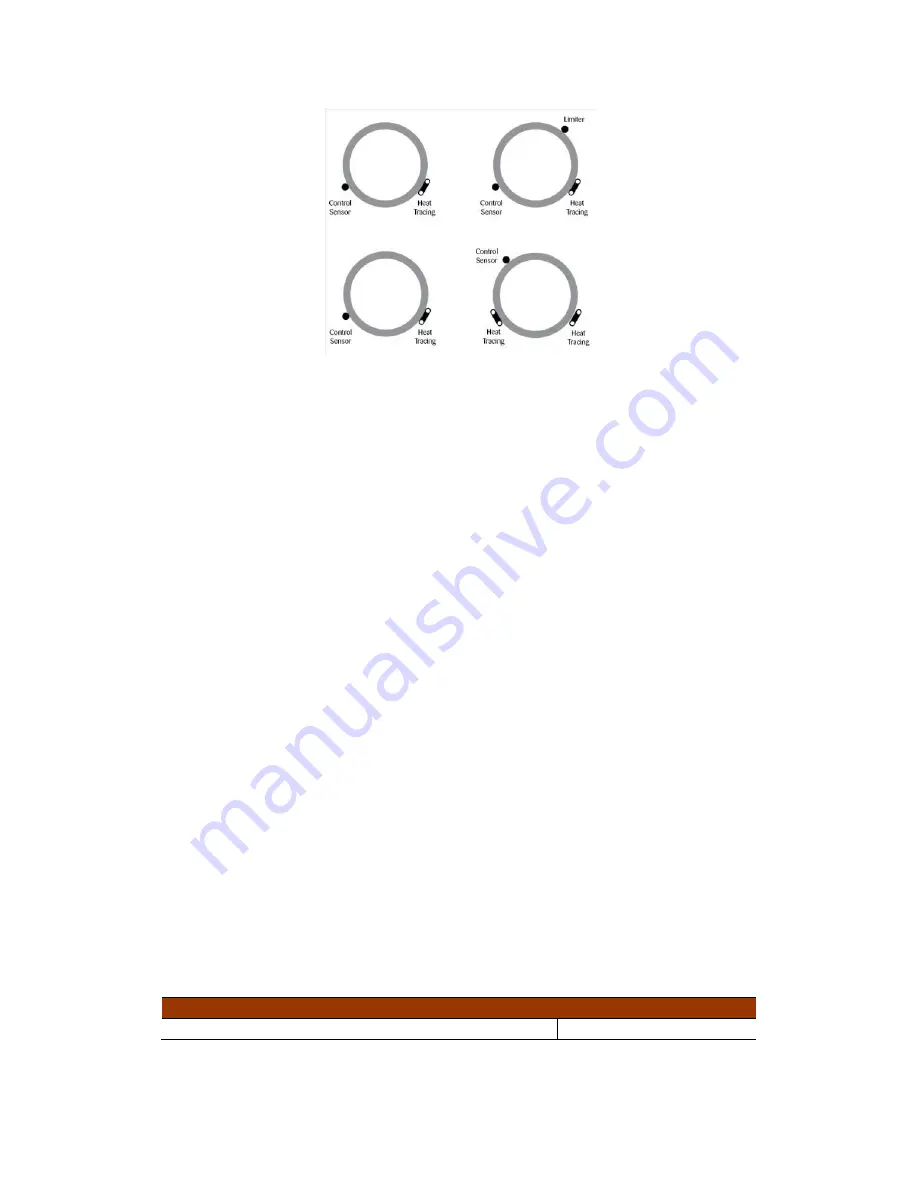

Figure 4.1:

RTD Sensor Location

Where RTD sensors are installed on the process piping, follow the guidelines

above. In special cases where the limiting temperature sensor is to be installed

on the heater itself, it is important to recognize that an offset should be

anticipated in the trip set-point to allow for sensor reading error and overshoot.

As a general rule, field RTD wiring and power wiring should not be routed in the

same conduit or proximity in a tray as the temperature signals can become

distorted and result in improper readings.

4.3 Power Distribution Wiring and Breakers

All field power wiring materials used shall be suitable for the intended service and

shall be rated for insulation service temperatures up to and exceeding 221°F

(105°C) unless higher values are otherwise noted in project specifications.

Power supply wiring from the power transformers to the power distribution panel

and distribution wiring to the heat trace circuits shall be rated for the heat trace

use voltage or higher and shall be of a sufficiently large wire size to minimize

voltage drop. Heat trace circuit breakers should be selected based on the type of

heat trace used, the service voltage, and the circuit current draw characteristics.

It is especially important when using self-regulating trace heaters to make sure

that the circuit breaker response curve type is coordinated with the startup

characteristic of the trace heater in a cold start condition. TCM2 controller circuit

breakers should have current ratings no higher than 15 A. In addition to the

controller circuit breaker, every heat trace circuit shall be provided with a circuit

breaker as a means for disconnection. All circuit breakers shall be easily

identifiable and accessible. All distribution wiring connections should be

tightened using a torque indicating screw driver to the levels indicated in

Table

4.1

.

Table 4.1:

Recommended Torque Values

Location of Terminals

Torque Values (Typical)*

Distribution Equipment

13.2 to 15.9 in. lbs. 1.49 to 1.80 N-m