Thermo Fisher Scientific

4-7 AutoXP Users Guide

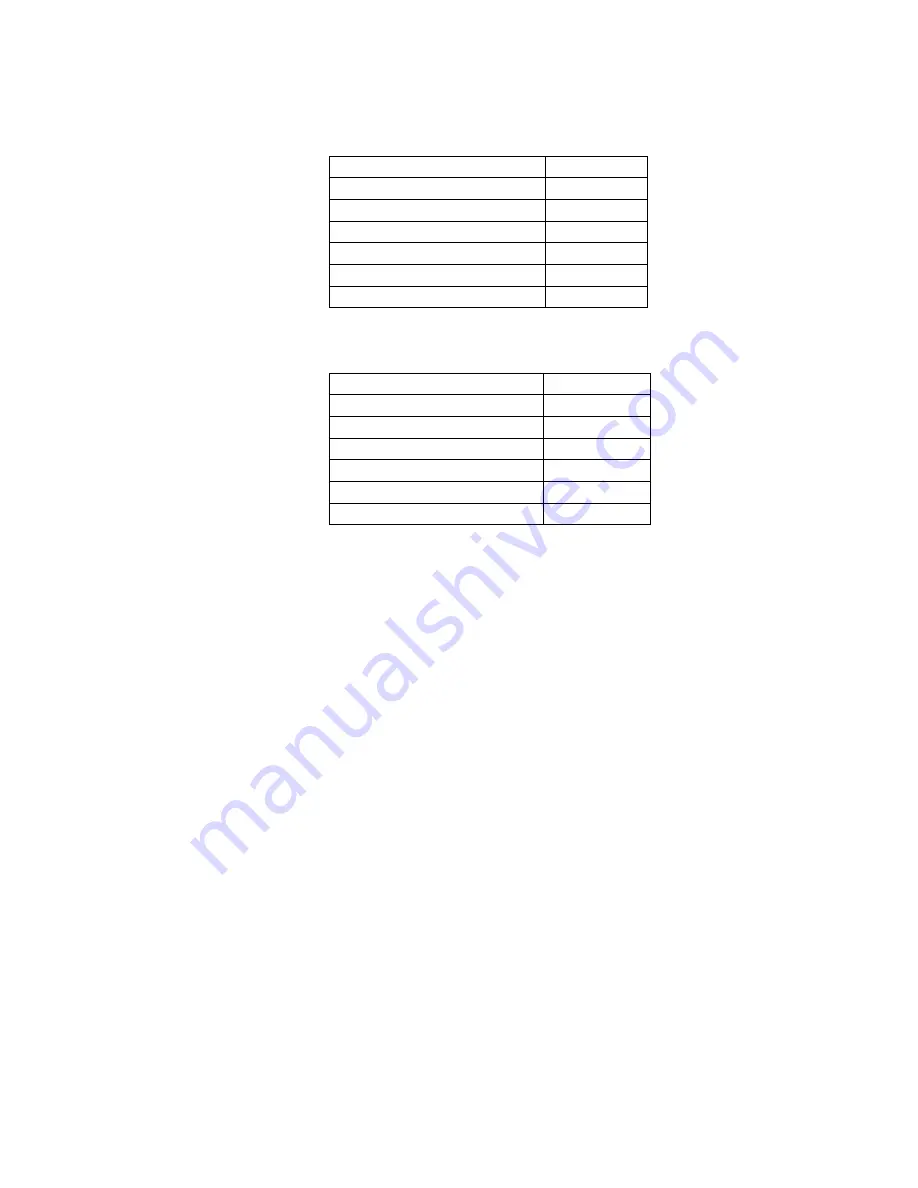

HART

Pressure Status [475 key sequence 1, 2, 1, 3]

PRESS: LO ALARM

OFF|ON

PRESS: LOLO Alarm

OFF|ON

PRESS: HI Alarm

OFF|ON

PRESS: HIHI Alarm

OFF|ON

PRESS: Out Of Range

OFF|ON

PRESS: ManOvrd

OFF|ON

PRESS: In Calibration

OFF|ON

RTD Temp Status [475 key sequence 1, 2, 1, 4]

RTD: LO ALARM

OFF|ON

RTD: LOLO Alarm

OFF|ON

RTD: HI Alarm

OFF|ON

RTD: HIHI Alarm

OFF|ON

RTD: Out Of Range

OFF|ON

RTD: ManOvrd

OFF|ON

RTD: In Calibration

OFF|ON

Summary of Contents for AutoXP

Page 1: ...AutoXP Users Guide 1 0511 006 July 2019 ...

Page 2: ......

Page 4: ......

Page 6: ......

Page 8: ......

Page 10: ...x AutoXP Users Guide Thermo Fisher Scientific Contents ...

Page 14: ......

Page 36: ......