55

C.

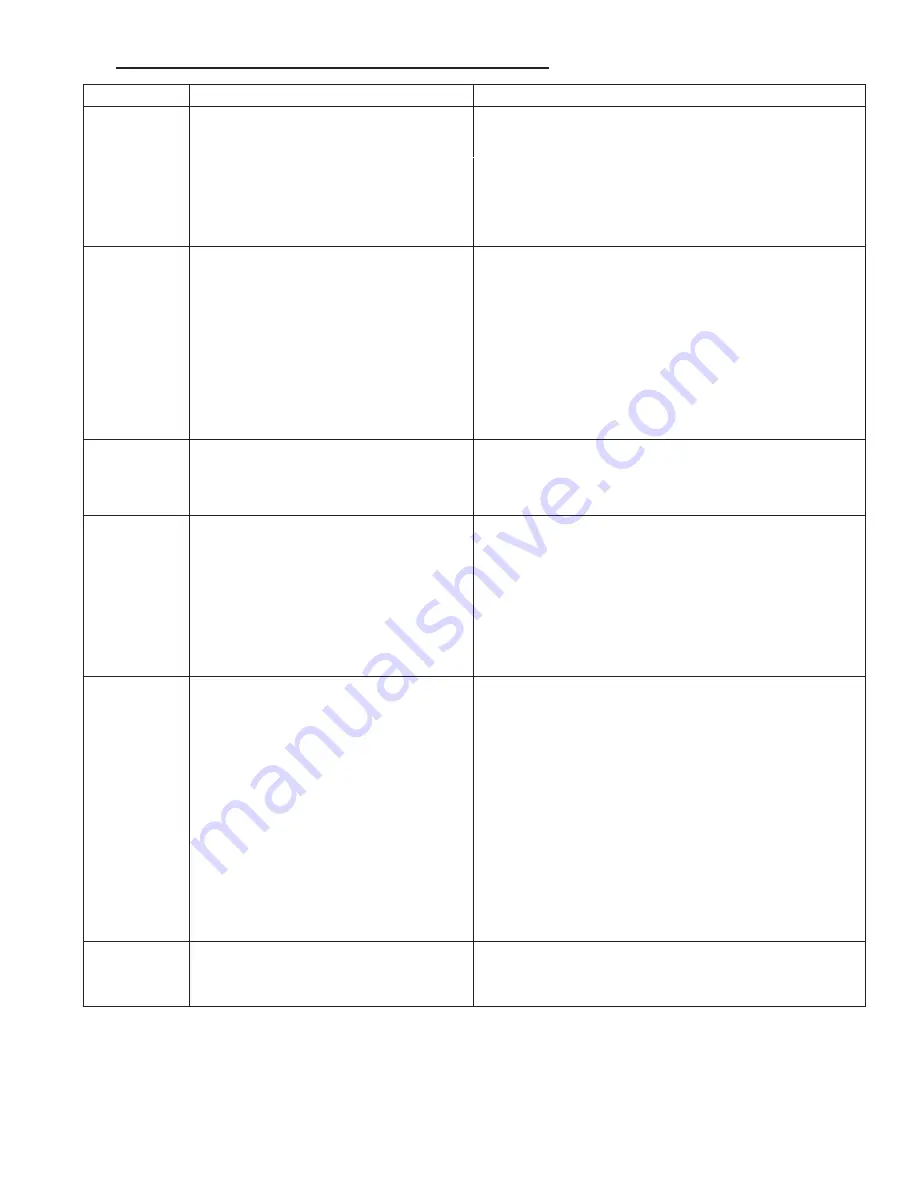

PERIODIC MAINTENANCE RECOMMENDED CHECK LIST

Frequency

Component/Item

Recommended Test

Daily

Maintenance

Boiler surroundings

Inspect the area to assure proper clearance to combustible materials,

gasoline, and other flammable vapors and liquids.

Gauges, monitors, and indicators

Make visual inspection and record readings.

Combustion Properties

Check combustion properties as specified in section VII, part D.

Burner flame

Make visual inspection of burner flame as stated in section VII, part D.

Low Draft, fan air pressure, and damper

position interlocks

Test low draft, fan, air pressure, and damper position interlocks

according to instructions if so equipped.

Weekly

Maintenance

Igniter

Make visual inspection, check flame signal strength; log.

Flame signal strength

Read and log flame signal meter, read for both pilot and main flames.

Flame failure detection system

Close manual fuel supply for (1) pilot, (2) main fuel cock, and/or

valve(s); check safety shutdown timing. Refer to section VII, Part D.

Firing rate control

Check firing rate control, place TSBC™ in manual mode and check

high and low firing settings for proper operation.

Pilot and/or main fuel valves

Open limit switch and make aural and visual check; check valve

position indicators and check fuel meters if so fitted.

Low-water fuel cutoff

Test low-water fuel cutoff device and alarm according to

manufacturer’s instructions.

Monthly

Maintenance

Flue, vent, stack, condensate drains,

and outlet dampers

Confirm that components are gas tight and free from obstructions to

flow.

Gas pressure interlocks

Test high and low gas pressure interlocks.

Water condition

Test condition of water, correct condition as needed.

Semi-Annual

Maintenance

Gauges, monitors, and indicators

Recalibrate all indicating and recording gauges.

Flame failure detection system

Check components.

Condensate drain tubes

Check drain tubes have liquid in trap and condensate is properly

directed.

Air filter

Check air filter as specified in section VII, Part D.

Interlocks and valves

Check piping and wiring of all interlocks and shut off valves if so

equipped.

Circulators and system pumps

Maintain according to manufacturers' instructions.

Annual

Maintenance

Flue, vent, stack, or outlet dampers

Confirm that components are gas tight and free from obstructions to

flow.

Combustion Properties

Check combustion properties as specified in section IV, Part I, Step 5.

Flame failure detection system

Conduct pilot turndown test according to manufacturer’s instructions.

This test is required annually and after any adjustments to flame

scanner mount or pilot burner.

Pilot and/or main fuel valves

Check all coils and diaphragms; test other operating parts of all safety

shutoff and control valves.

Pilot and/or main fuel valves

Perform leakage test on pilot and main gas and/or oil fuel valves, in

accordance with instructions.

Flame safeguard

Test purge timing according to manufacturer’s instructions.

Air Filter

Replace.

Boiler trim

Remove lower front jacket panel and check for any signs of corrosion

and leaks.

High limit and operating temp. controls

Test proper operation.

As-Required

Low-water fuel cutoff

Recondition or replace.

Safety relief valves

Test safety relief valves in accordance with ASME Boiler and Pressure

Vessel Code, Sections VI and VII.

Summary of Contents for EVS SERIES

Page 14: ...14 Figure 4 Vertical Pressurized Venting ...

Page 16: ...16 Figure 5 Typical Negative Pressure Conventional Venting ...

Page 18: ...18 Figure 7 Vertical Air Intake Piping ...

Page 27: ...27 Figure 9a 208 230 460V 1 3 ph 60 Hz Supply Power Wiring Schematic ...

Page 28: ...28 Figure 9b 120V 1ph 60Hz Supply Power Wiring Schematic ...

Page 29: ...29 Figure 9c Standard UL FM CSD 1 Wiring Diagram EVS 500 2000 ...

Page 31: ...31 Figure 9e Standard UL FM CSD 1 EVS 2000S 3000 ...

Page 35: ...35 Figure 11 Modular System Horizontal Air Intake Piping ...

Page 36: ...36 Figure 12 Modular System Vertical Air Intake Piping ...

Page 37: ...37 Figure 13 Modular System Typical One Pipe Water Piping ...

Page 38: ...38 Figure 14 Modular System Typical Primary Secondary Water Piping ...

Page 39: ...39 Figure 15 Modular System Typical Primary Secondary without System Pump ...

Page 40: ...40 Figure 16 Modular System Typical Reverse Return Water Piping ...

Page 41: ...41 Figure 17 Modular System Reverse Return with System Pump Only ...

Page 42: ...42 Figure 18 Modular System Typical Primary Secondary with Reverse Return ...

Page 58: ...58 Figure 19 Combustion Chamber Assembly ...

Page 60: ...60 Figure 20 Burner Assembly FRONT VIEW TOP VIEW ...

Page 62: ...62 Figure 21 UL FM CSD 1 Main Gas Train Assembly ...

Page 65: ...65 Figure 22b DB B Gas Train 500 750 Figure 22c DB B Gas Train 1000 2000 ...

Page 70: ...70 Figure 23 Jacket Panels ...

Page 74: ...74 Figure 25 Pilot Assembly Bishop Design ...

Page 88: ...88 NOTES ...

Page 89: ...89 NOTES ...

Page 90: ...90 NOTES ...

Page 91: ...91 NOTES ...