Texmate, Inc. Tel. (760) 598-9899 • www.texmate.com

FL-B101Q-HZ_manual (d0059)

Page 9

To calibrate the Analog Output you must be able to input two input signals. Usually the mini-

mum input (LO Input) and the maximum (HI Input) signals are used for maximum

accura-

cy.

For example the five steps to obtain an Analog Output of 4mA to 20mA for an input of 0 to

10V are:

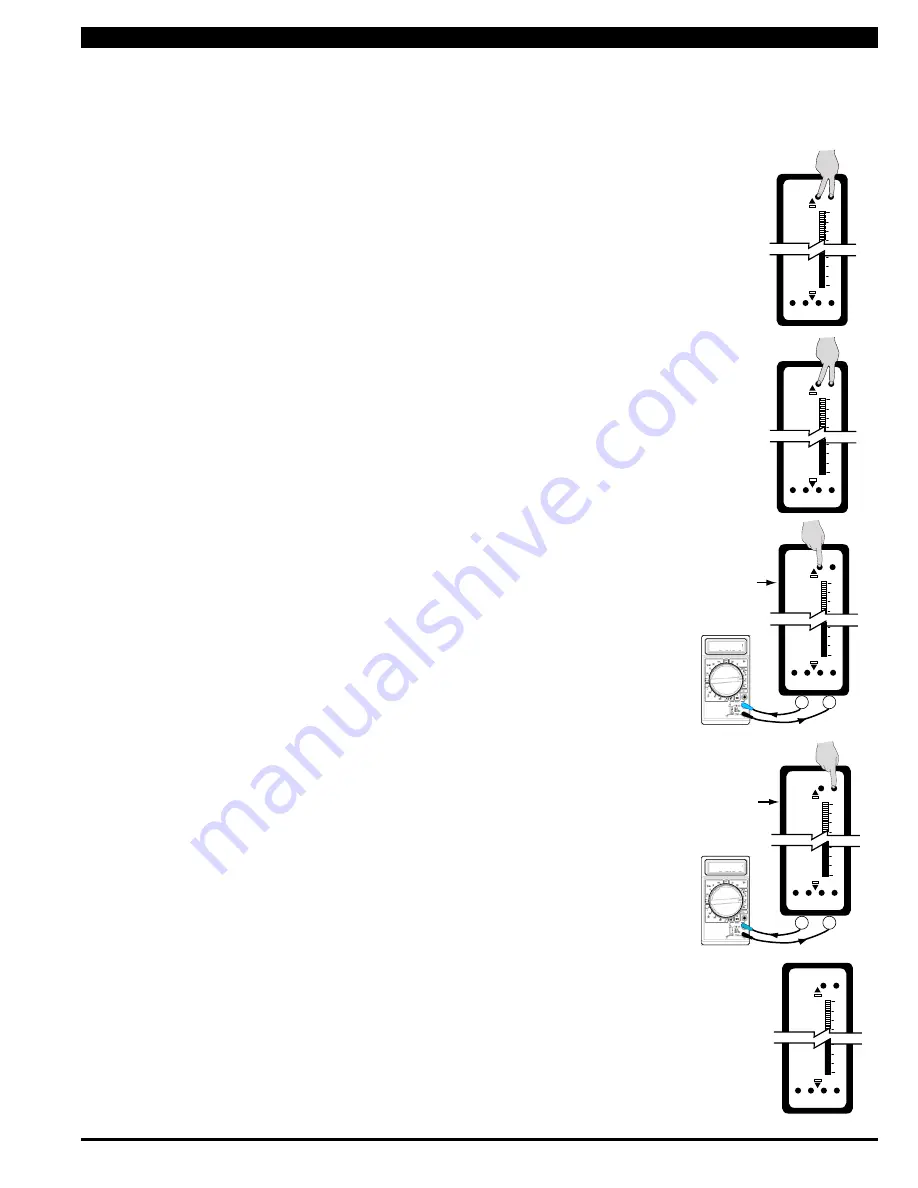

STEP A ACCESS THE ANALOg CALIBRATION MODE

1) Confirm the internal analog output module is installed and that the required

voltage or current output option is selected.

2) Turn OFF the power to the bargraph.

3) Hold down the ZERO and SPAN buttons simultaneously and re-power the

bargraph. The ZERO button will now function as the LO button and the SPAN

button will now function as the HI button for calibrating the Analog Output.

STEP B RESET THE ANALOg OuTPuT SCALINg

1) Press the LO and HI buttons simultaneously and hold them down for 2

seconds. This will reset the analog output scaling to the default value. The

default analog output scaling is approximately 0 to 20mA (0 to 10V if voltage

output option is selected) for an input that is 0 to 100% of the range selected

on the input signal conditioner.

STEP C CALIBRATE ANALOg OuTPuT FOR LO SIgNAL

1) Apply the low input signal (0V in this example) to the meter.

2) Connect an external multimeter to the analog output pins (Pins 17 and 18).

3) Using the LO button adjust the analog output as measured on the external

multimeter to be the required value. (4mA in this example). When the LO

button is pressed, the UP or DOWN indicator LED shows the direction of

change. To reverse the direction of change release the LO button and press

down again. Initially the output changes very slowly, but speeds up as the LO

button remains pressed down. The analog output for a low input can be set

in this step to any value in the range of 0 to 20mA or 0 to 10V ( if the voltage

output option is selected).

STEP D CALIBRATE ANALOg OuTPuT FOR HI SIgNAL

1) Next apply the high input signal (10V in this example) to the meter.

2) Using the HI button, adjust the analog output as measured on the external

multimeter to be the required value. (20mA in this example). When the HI

button is pressed the UP or DOWN indicator LED shows the direction of

change. Release the HI button and press again to reverse the direction of

change. Initially the output changes very slowly, but speeds up as the HI button

continues to remain pressed. This output may be higher or lower than the value

set in Step C, and may be any value in the range of 0 to 20mA or 0 to10V. This

allows the easy reversal of analog output that is required in some applications.

STEP E EXIT THE ANALOg OuTPuT CALIBRATION MODE

1) Turn OFF the power to the bargraph

2) Re-power the bargraph. The two buttons will now return to their original

function of ZERO and SPAN.

3) Calibration is now complete and the bar is scaled for a 0 to 10V input to

produce an analog output of 4 to 20mA.

Turn Power ON

while holding

down the Zero

and Span Buttons

simultaneously

100

0

SP1 SP2 SP3 SP4

Zero Span

Apply 0 V to the

Input Signal Pins

100

0

SP1 SP2 SP3 SP4

Zero Span

+

–

Adjust the Analog

output to 4.00mA with

the LO (zero) button

17

18

4.00

Apply 10 V to the

Input Signal Pins

100

0

SP1 SP2 SP3 SP4

Zero Span

Adjust the Analog

output to 20.00mA with

the HI (span) button

17

18

20.00

+

–

Turn Power OFF

and then back

ON to exit

Analog output

Calibration Mode

100

0

SP1 SP2 SP3 SP4

Zero Span

When the optional analog output module is installed, an independently calibrated 16 bit isolated, voltage or current analog output is available.

The analog signal is independently scaled to the input signal and not to the bargraph display. It is important to note that the Analog

Output is completely independently of the bargraph display. This means for example that the bargraph display may be scaled to go from zero

to full scale as the input changes from 0 to 5V, while at the same time, the analog output is scaled to go from 4 to 20mA as the input changes

from 2 to 3V. Rescaling the bargraph or the analog output will not affect the scaling of the other.

Analog Output Scaling and Calibration

Reset the analog

output scaling by

pressing the LO (zero)

and HI (span) buttons

simultaneously

for 2 secs.

100

0

SP1 SP2 SP3 SP4

Zero Span