Texmate, Inc. Tel. (760) 598-9899 • www.texmate.com

Page 6

FL-B101Q-HZ_manual (d0059)

Note: To calibrate the bargraph you must be able to input two input signals. Usually the minimum

input (LO Input) and the maximum input (HI Input) signals are used for optimum accuracy. However

a scaling can be accomplished with any two signals that are higher or lower than each other by more

than 5% of fullscale and are not greater than +2.1VDC or less than -1.05VDC.

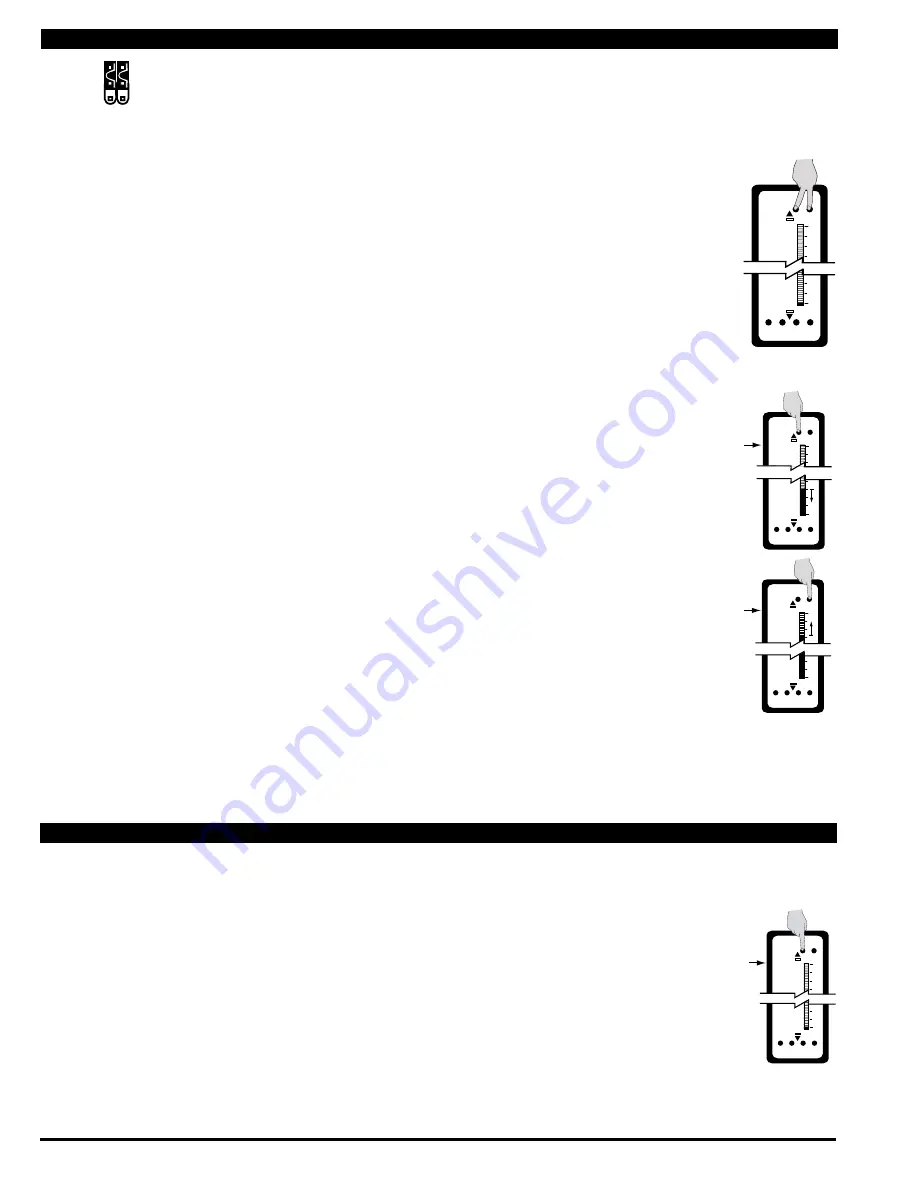

STEP C SET THE LOW INPuT SIgNAL READINg ON THE BAR

1) Apply the LO input signal (4ma in this example) to the input pins.

2) Using the ZERO button adjust the bar down to the required position.

STEP D SET THE HIgH INPuT SIgNAL READINg ON THE BAR

1) Apply the high input signal (20mA in this example) to the input pins.

Using the SPAN button adjust the bar to the required position.

This position could be higher or lower than the position adjusted in

Step 2. The scaling for an input of 4 to 20mA is now complete.

Apply 4 mA

to the

Input Pins

and adjust

bar display

to the required

position

100

0

SP1 SP2 SP3 SP4

Zero Span

Apply 20 mA

to the

Input Pins

and adjust

bar display

to the required

position

100

0

SP1 SP2 SP3 SP4

Zero Span

Standard Display Mode Calibration Procedure

One Point Quickset Rescaling and Calibration Procedure

ONE POINT RECALIBRATION

As explained earlier, the FL-B101Q bargraph is calibrated using two point calibration. Once a bargraph is calibrated, the

low end of the range may be then recalibrated without affecting the calibration of the high end, and vice versa.

For example, take an FL-B101Q that has been calibrated to read zero to full scale for an input of 4 to

20mA. If now the scaling has to be changed to read zero to full scale for an input of 0 to 20mA, only

the low (4 mA) end needs to be recalibrated. The high (20 mA) end of the scaling is left untouched,

and so does not change. The following one point recalibration procedure is used for this purpose.

STEP A RECALIBRATE THE LOW INPuT SIgNAL READINg ON THE BAR

1) Apply the LO input signal (0ma in this example) to the input pins.

The first segment will flash, indicating an under range condition.

2) Using the ZERO button adjust the bar up to the required position.

3) The FL-B101Q has now been recalibrated to read zero to fullscale

for a 0 to 20 mA input.

Apply 0 mA

to the Input Pins

and adjust

bar display

to the required

position

100

0

SP1 SP2 SP3 SP4

Zero Span

STEP A REVIEW THE INPuT MODuLE STATuS

1) Confirm that the correct range and input is selected on the input signal con-

ditioning module.

Note: When undertaking an initial set up and primary scaling and calibration of the meter

it is best to start with a reset of the scaling.

STEP B RESET THE SCALINg

1)Apply power to the meter and press the ZERO and SPAN buttons simultaneously for

2 seconds. This erases any previously memorized scalings, and resets the scaling to

the factory default, of approximately zero to full scale, for an input, that is 0 to 100% of

the range selected on the input signal conditioner.

Standard or Center Zero Display Mode may be selected, depending on the Operating Mode selected. If

the standard display mode is not already selected open the meter case as showing on page 4 and move the

jumper clips on the display mode select header to the OFF position.

Standard Display with

Jumper Clips in OFF

position

CH1

CH2

100

0

SP1 SP2 SP3 SP4

Zero Span

Reset the scaling

to the default value

on by pressing

the Zero and

Span buttons

simultaneously

for 2 secs.