Texmate, Inc. Tel. (760) 598-9899 • www.texmate.com

FL-B101Q-DCA _ FL-B01Q-DCV (d0084)

Page 7

Setpoint Adjust

The bargraph has the option to have up to 4 setpoints (two 9A Form C relays and two 4A Form A relays) installed. Each relay may

be set to activate either above or below its setpoint by inserting jumper clips on the Relay Activation header which is located on the

Display Driver Board. See the layout diagram on Page 4 for the exact location. The steps to setup the setpoints are as follows:

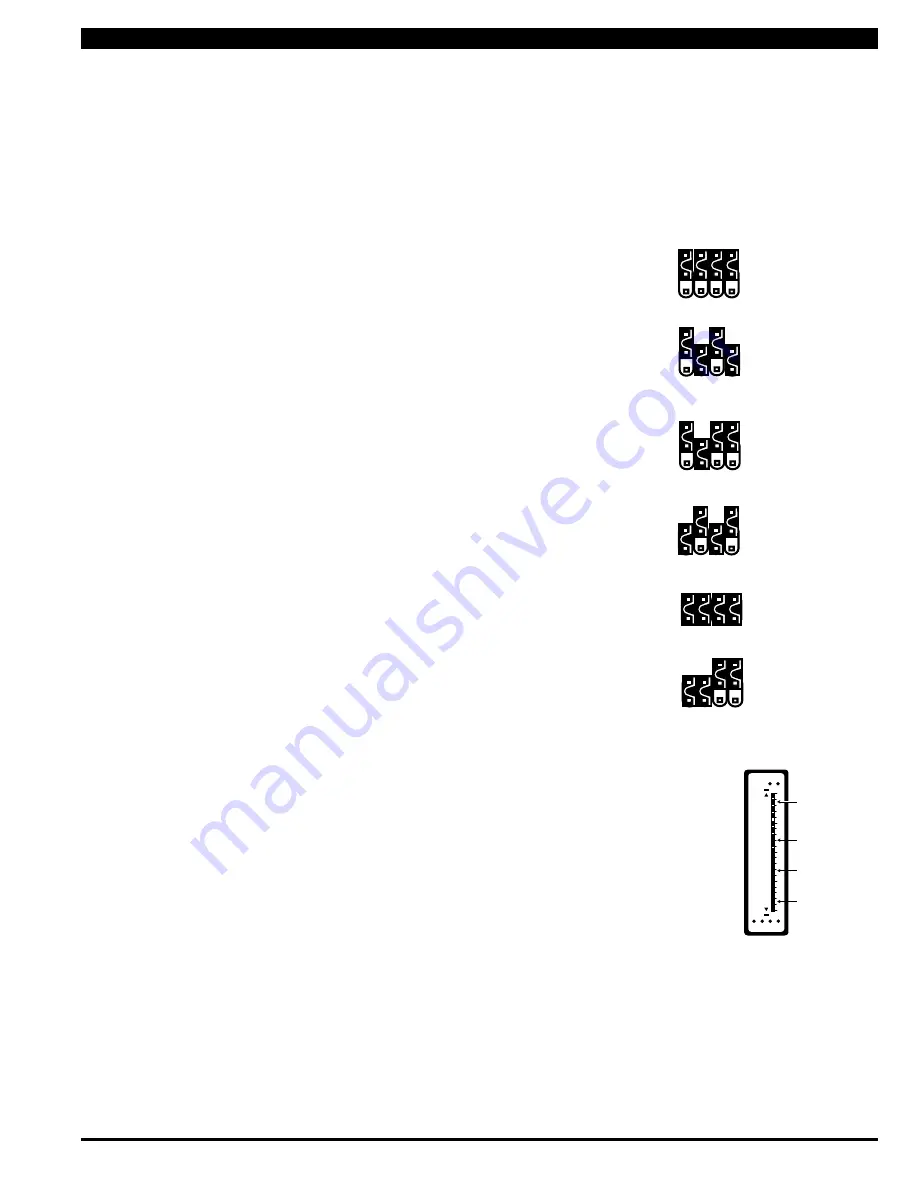

1) SELECT THE RELAY ACTIVATION MODE FOR EACH INSTALLED RELAY

Make sure that the required relays have been installed in the meter. Refer to the component layout on Page 11 for relay posi

-

tions. If a jumper clip is installed in a specific relay position on the Relay Activation Mode Header, that relay will activate when

the display bar is lower that the programmed setpoint. If no jumper clip is installed in a specific relay position on the Relay

Activation Mode Header, that relay will activate when the display bar is equal to or higher that the programmed setpoint. The

Diagrams below show some of the various possibilities for relay activation.

Default

SP1, SP2, SP3, and SP4 all activate when input is equal to or higher than set point.

SP2 and SP4 activate when input is lower than set point. SP1 and SP3 activate when input

is equal to or higher than set point.

SP2 activate when input is lower than set point. SP1, SP3 and SP4 activate when input is

equal to or higher than set point.

1

3 4

2

SP

1

3 4

2

SP

1

3 4

2

SP

SP1 and SP3 activate when input is lower than set point. SP2 and SP4 activate when input

is equal to or higher than set point.

SP1, SP2, SP3, and SP4 all activate when input is lower than set point.

1

3 4

2

SP

SP1 and SP2 activate when input is lower than set point. SP3 and SP4 activate when input

is equal to or higher than set point.

1

3 4

2

SP

1

3 4

2

SP

100

0

25

50

75

SP1 SP2 SP3 SP4

Zero Span

SP2

SP1

SP3

SP4

2) ADJuST THE SETPOINT FOR EACH RELAY

The setpoint for each relay is set by the front panel buttons marked SP1, SP2, SP3 and

SP4. When a front panel button is pressed and held down, the associated setpoint is directly

changed. The direction of change will be either up or down, as indicated by the UP and DOWN

indicator LEDs. After the indicator LED lights up there is a 0.5 second delay before any change

occurs. To reverse the direction of change, release the button and then press down again. As

there are no menus or sub-menus to navigate, the programming and setup is quick and easy.

Setpoints are indicated on the bar display by an ON segment if the bar is below the setpoint

and with an OFF segment if the bar display is above the setpoint.