Texmate, Inc. Tel. (760) 598-9899 • www.texmate.com

Page 2

FL-B101Q-DCA _ FL-B01Q-DCV (d0084)

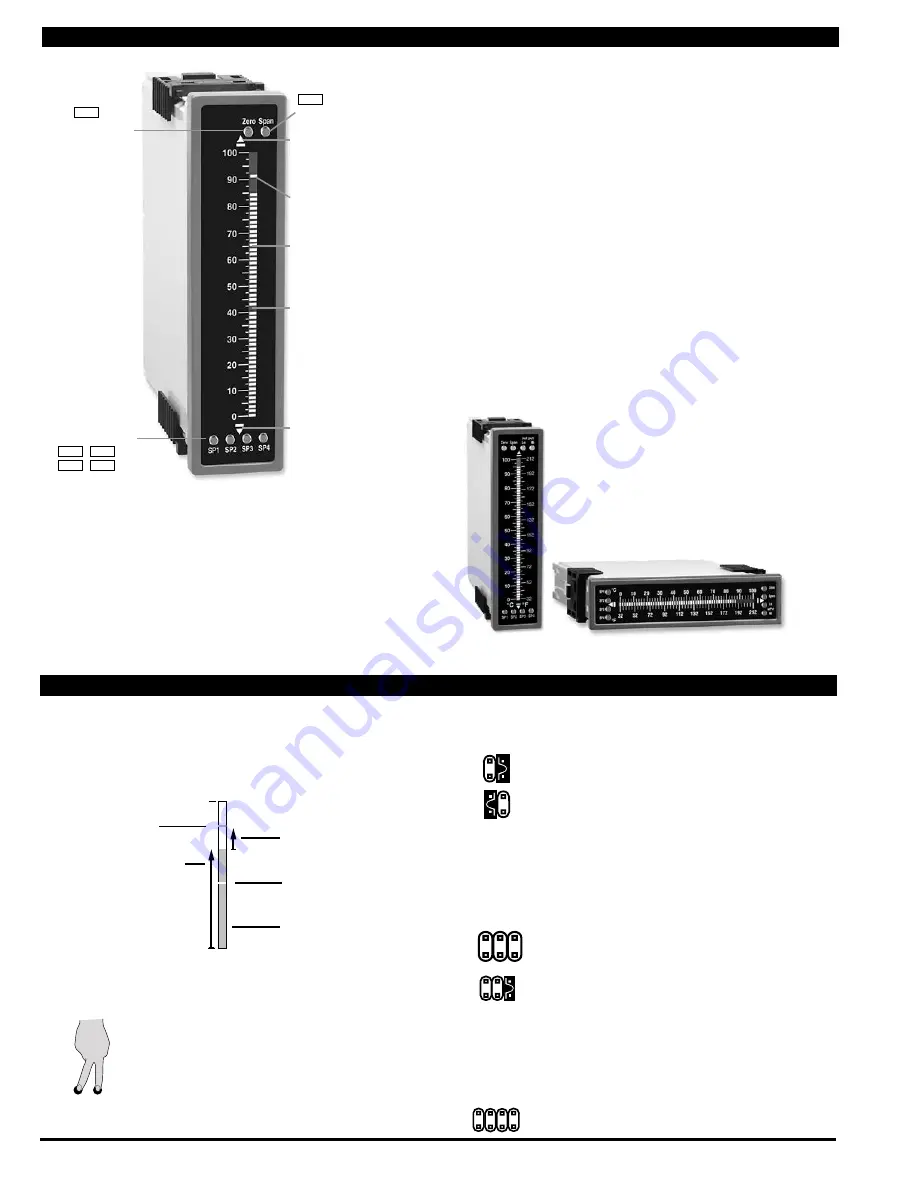

Standard or Center Zero Display Mode Select Header

• Jumper clips enables standard

display on CH1 and CH2.

• Jumper clip to enable Center

Zero display.

Operating Mode Select Header

This header selects one of the two basic operating

modes presently available for this meter.

Mode 0 Bargraph with four set points displayed on

bargraph display.

Mode 3 Enables the Hysteresis mode for tank

filling or tank emptying applications.

Relay Activation Mode Select Header

When no jumper clips are installed the relays will

activate when the display exceeds the set point.

Any relay that has a jumper clip installed will

activate when the display is less than the set point.

CH1

CH2

CH1

CH2

MODE

1

3

2

Controls and Indicators

Controls and Indicators

101 Segment Bar

Setpoint indicated

by an OFF Segment

UP Button Indicator

DOWN Button

Indicator

Setpoint indicated

by an ON Segment

Quickset Programming

This bargraph features Texmate's unique QUICKSET PROGRAMMING.

When a front panel button is pressed the associated function is directly

changed. The direction of change will be either up or down, as indicat

-

ed by the UP and DOWN indicator LEDs. After the indicator LED lights

up there is a 0.5 second delay before any change occurs. When a but

-

ton is released and pressed again the direction of change is reversed.

As there are no menu or sub-menus to navigate, the programming and

setup is quick and

Span Buttons

Span

Zero Buttons

Zero

Set Point Button

SP1

SP2

SP3

SP4

Front Panel Buttons

Zero Button

The Zero Button sets the Channel 1 low input signal scaling.

Span Button

The Span Button sets the Channel 1 high input signal scaling.

SP1, SP2, SP3 and SP4 Buttons

These buttons setup the corresponding setpoints.

Setpoint Indication

The position of setpoints on the bargraph display are indicated by

an ON segment if the bargraph display is below the setpoint, and

by an OFF segment if the bargraph display is above the setpoint.

(See the drawing above)

To explain software programming procedures, logic diagrams

are used to visually assist in following programming steps. The

following symbols are used to represent the functions and dis

-

plays of the meter:

When two fingers are shown side by

side, the two corresponding buttons must

be pressed at the same time to initiate an

indicated function.

Controls and Indicators

Glossary of Programming Symbols and Modes of Operation

Input Hi

Input Low

This arrow represents

the direction and level

of an input signal

Small arrow shows

direction the bar

-

graph display has

moved or will move.

Shading indicates

bargraph is ON in

this area.

Setpoint indicated by

an OFF segment.

Setpoint indicated by

an ON segment.

Zero Span

Center Bar Display Option

This display option can be selected

when a dual scale is required. A

custom face plate is required for dual

scales. Tri-Color option is available

only for the Center Bar display.

MODE

1

3

2

RELAYS

1

3 4

2