FF-MM-370-REV - 01

Page 11

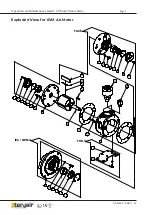

Operation and Maintenance Guide 6 VM Air Motor Series

Note - Adaptor Included On BSPT Models Only

“*”

Bill of Materials for 6VM Series (SS)

Sr.

No

Description

Part

Number

FACE

FOOT

IEC

NEMA

6VMLAS 6VMLOS 6VMSAS 6VMSOS 6VMDAS 6VMDOS 6VMNAS 6VMNOS

1

MOTOR HOUSING

805 07 01

1

-

1

-

1

-

1

-

1

MOTOR HOUSING (LUBE FREE) 805 07 01LF

-

1

-

1

-

1

-

1

2

FRONT FLANGE

805 07 02

1

-

1

-

-

-

-

-

2

FRONT FLANGE (LUBE FREE)

805 07 02LF

-

1

-

1

-

-

-

-

2

IEC FLANGE

805 07 04

-

-

-

-

1

-

-

-

2

IEC FLANGE (LUBE FREE)

805 07 04LF

-

-

-

-

-

1

-

-

2

NEMA FLANGE

805 07 05

-

-

-

-

-

-

1

-

2

NEMA FLANGE (LUBE FREE)

805 07 05LF

-

-

-

-

-

-

-

1

3

REAR FLANGE

805 07 03

1

-

1

-

1

-

1

-

3

REAR FLANGE (LUBE FREE)

805 07 03LF

-

1

-

1

-

1

-

1

4

ROTOR SHAFT

805 27 01

1

1

1

1

-

-

-

-

4

ROTOR SHAFT - IEC

805 27 02

-

-

-

-

1

1

-

-

4

ROTOR SHAFT - NEMA

805 27 03

-

-

-

-

-

-

1

1

5

REAR BEARING CAP

805 27 04

1

1

1

1

1

1

1

1

6

FRONT BEARING CAP

805 27 05

1

1

1

1

-

-

-

-

7

BALL BEARING 2Z/ZZ

805 50 02

2

2

2

2

1

1

1

1

8

BALL BEARING 2Z/ZZ

805 50 01

-

-

-

-

1

1

1

1

9

O' RING

805 40 01V

2

2

2

2

1

1

1

1

10

OIL SEAL

805 60 01V

1

1

1

1

-

-

-

-

10

OIL SEAL

805 60 02

-

-

-

-

1

1

1

1

11

ALLEN BOLT

803 90 01

3

3

3

3

3

3

3

3

12

KEY

805 27 06

1

1

1

1

-

-

-

-

12

KEY (IEC)

805 27 07

-

-

-

-

1

1

-

-

12

KEY (NEMA)

803 27 06

-

-

-

-

-

-

1

1

13

ROLL PIN

804 90 06

4

4

4

4

4

4

4

4

14

ALLEN BOLT

171 27 47S

12

12

12

12

12

12

12

12

15

ROTOR BLADE

805 39 02

4

4

4

4

4

4

4

4

16

PIN

805 27 08

2

2

2

2

2

2

2

2

17

SHIM

805 37 01

2

2

2

2

2

2

2

2

18

SPRING WASHER

805 90 06

12

12

16

16

12

12

12

12

19

SPRING WASHER

811 90 04

3

3

3

3

3

3

3

3

20

LEAF SPRING

805 51 02

4

4

4

4

4

4

4

4

21

CSK BOLT

805 90 05

4

4

4

4

-

-

-

-

22

CIRCLIP

805 90 03

-

-

-

-

1

1

1

1

21

FOOT

805 82 01

-

-

1

1

-

-

-

-

24

ALLEN BOLT

803 90 03

-

-

4

4

-

-

-

-

25

MUFFLER

804 50 03

1

1

1

1

1

1

1

1

26* ADAPTOR

171 07 05S

1

1

1

1

1

1

1

1