FF-MM-370-REV - 01

Page 8

Operation and Maintenance Guide 6 VM Air Motor Series

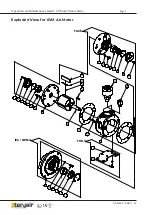

Dis assembly and Re-assembly

Disconnect air supply and vent all air lines.

Air stream from product may contain solid or

liquid material that can result in eye or skin

damage.

Flush this product in a well ventilated area.

Do Not use kerosene or other combustiblesol-

vents to flush this product.

Failure to follow these instructions can result

in eye injury or other serious injury.

Always open from the back side first.

Use proper tools to open the fasteners.

a. Unscrew Allen Bolts(11) with Spring

Washer (19) from Bearing Cap (5) from

Rear Flange (3). Remove O-ring (9) from

Bearing Cap (5) and replace with new one

(if found damaged).

b. Unscrew Allen Bolts (14) with Spring

Washer (18) from Rear Flange (3) & re-

place Shim (17) with new one (if found

damaged).

c. Now remove Ball bearing (7) from Rear

Flange (3) using mallet and replace it with

new one (if worn-out).

d. Now remove the Rotor Shaft (4) with Rotor

Blades (15) from the Motor Housing (1),

Now remove the Rotor Blades (15), Leaf

Spring (20) & Pin (17) from Rotor Shaft (4)

and replace them with new ones (if found

damaged).

e. To remove the Front Bearing Cap (6) from

Front Flange (2), unscrew CSK Bolt (21)

from it. The O-ring (9) and Oil Seal (10)

can be now removed from Front Bearing

Cap (6). Replace with new ones (if found

damaged).

f. Now remove Ball bearing [ (7) for Face/

Foot mount models and (8) for IEC /Nema

mount models) from Front Flange (2) by

using puller. Replace it with new ones (if

worn-out).

g. After installing bearing & seal then install

the Front Bearing Cap (6) on Front Flange

(2) by fastening CSK Bolts (21).

h. Now insert Pins (16) into the Rotor

Shaft’s (4) through holes (use small

amount of grease to prevent Pins to fall

during assembly). Now insert the Rotor

Shaft (4) into the Motor Housing (1) and

Front Flange bearing using press/mallet

precisely and ensure that rotor face is not

above the housing face.

i. Now place the Leaf Spring (20) on Rotor

Blades (15), ensure that leaf spring one

end is inside the slot of Rotor Blade (15).

j. Insert the above blade assembly one at a

time into Rotor Shaft (4).

k. Now follow the above steps ‘c’ & ‘b’ in

reverse manner to assemble the motor.

l. Now after assembly, ensure that Rotor

Shaft (4) is rotating smoothly inside, else

tap lightly on the rotor shaft front end or

rear end until you obtain smooth rotation

of Rotor Shaft (4).

m. Once smooth rotation is achieved follow

the step ‘a’ in reverse manner and com-

plete the assembly.