17

Maintenance

CAUTION

: Replacement parts are not lubricated.

Replacement parts must be lubricated at

time of assembly and during use, per the lube

manufacturer’s recommendations.

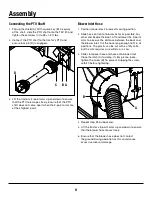

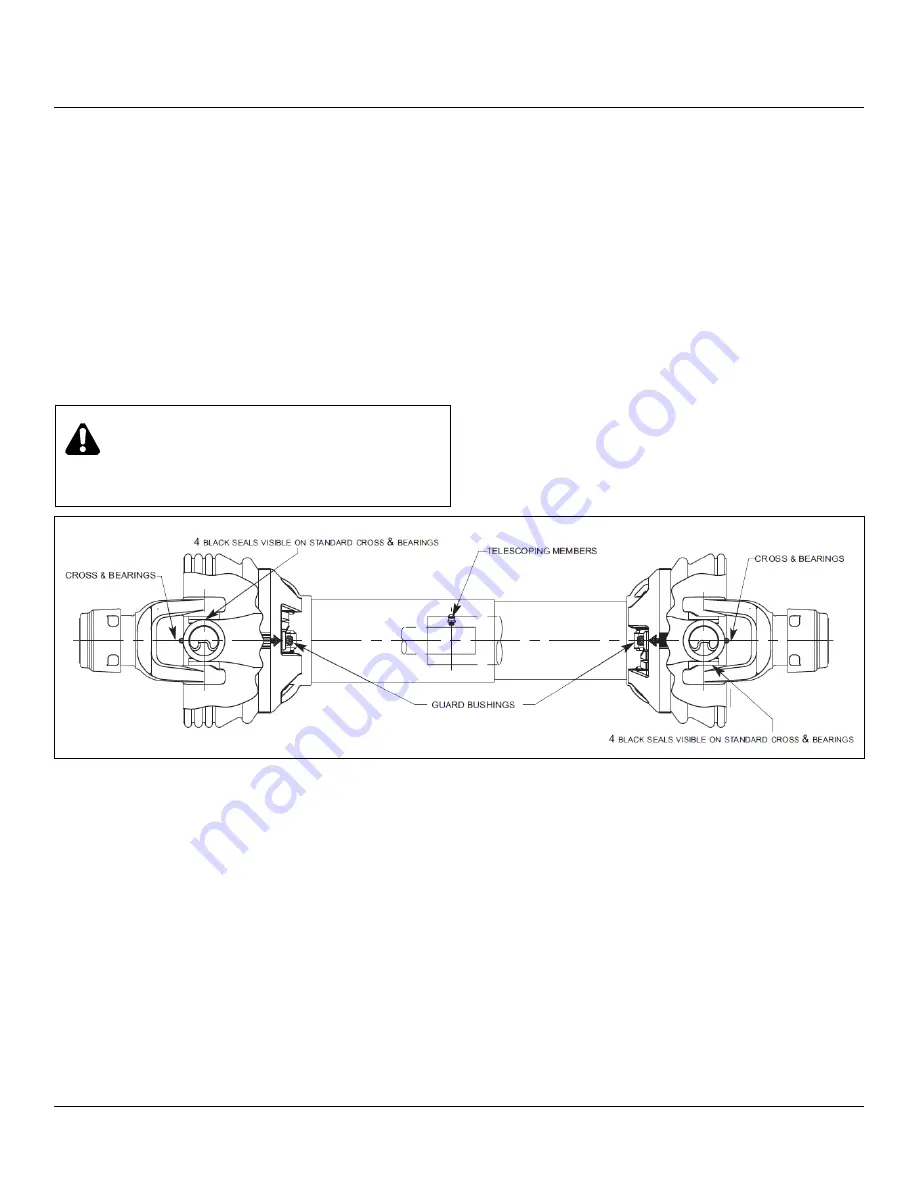

PTO Shaft Lubrication

NOTE: See page 15 for recommended service intervals in

Maintenance Schedule table.

1.

Lubricate all fittings with lithium soap compatible E.P.

grease meeting the N.L.G.I. #2 specifications and

containing no more than 1% molybdenum disulfide.

2.

An E.P. grease meeting N.L.G.I. #2 specifications

and containing 3% molybdenum disulfide may be

substituted in the telescoping members only.

3.

The rotating guard bushings should be lubricated

upon replacement.

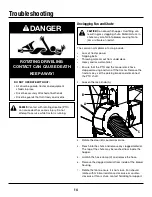

Cleaning and Seasonal Storage

1.

Empty the hopper before removing from the tractor.

2.

Raise the hopper lid and clean the screen using a

cloth or soft-bristle brush.

3.

Carefully remove any debris stuck to the fan and spray

with a light oil to prevent rusting.

4.

Remove shields and clean out debris stuck in drive

frame. Reinstall the shields before storing.