November 2006

38

AL4000 Light Tower

Part No. 833002 Rev A

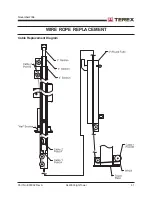

WIRE ROPE REPLACEMENT

CRITERIA FOR REPLACEMENT OF WIRE ROPE – TEREX LIGHT TOWERS

The wire ropes used to raise and lower the masts on a TEREX Light Tower are probably some of

the most important mechanical parts used in day-to-day operation of the machinery. It is there-

fore very important that the cables be inspected on a frequent basis (once a month) for wear and

tear, and immediately in the event of possible damage due to operator error in using the winch, or

possible damage from other equipment.

NORMAL WEAR AND TEAR

When used properly, the wire ropes should give years of trouble-free service, depending on how

often the masts are raised and lowered. The rule of thumb at TEREX is that if the tower is

raised

and lowered an average of

once per day

, that the cables

should be replaced every two

years of service

.

NORMAL INSPECTION

The wire ropes are constructed of 7 strands of 19 plow steel wires each twisted together, and

then the assembly galvanized to resist corrosion. Using a wadded-up cloth or heavy leather

gloves (to avoid being pricked by a broken wire), run a hand up and down a length of the cable.

If any exterior wires are broken, they will lift up from main body of the cable and become visible.

For any given 1 foot of cable length; if there are 4 or more wires each, on any 2 or more strands

broken, the suspect rope

should be replaced immediately

.

DAMAGE INSPECTION

If any nicks (partial strand cut through), kinks (permanent bends), or weld spatter on the cable

(from field service) are observed, the suspect wire rope

should be changed immediately.

If

there is a crushed spot somewhere on the wire rope, it should be

replaced only

if the width of

the crushed spot exceeds 1-1/4 times the nominal diameter of the cable (5/16” on a 1/4” cable,

and 7/32” on a 3/16” cable), or if there are broken wires at the point of damage.

Summary of Contents for 833002

Page 25: ...November2006 Part No 833002 Rev A AL4000LightTower 25 SPECIFICATIONS DIMENSIONS...

Page 36: ...November2006 36 AL4000LightTower Part No 833002 Rev A MODEL NUMBER IDENTIFICATION...

Page 43: ...November2006 Part No 833002 Rev A AL4000LightTower 43 Wiring Diagrams Section...

Page 44: ...November2006 44 AL4000LightTower Part No 833002 Rev A FixtureWiring Diagram...

Page 45: ...November2006 Part No 833002 Rev A AL4000LightTower 45 1000MH Ballast Diagram...

Page 46: ...November2006 46 AL4000LightTower Part No 833002 Rev A 1000HPS Ballast Diagram...

Page 47: ...November2006 Part No 833002 Rev A AL4000LightTower 47 AC Wiring For A Light Tower Diagram...

Page 48: ...November2006 48 AL4000LightTower Part No 833002 Rev A DC Engine Wiring Diagram...

Page 49: ...November2006 Part No 833002 Rev A AL4000LightTower 49 AC Light Tower Wiring Diagram Perkins...

Page 50: ...November2006 50 AL4000LightTower Part No 833002 Rev A Consolidated Coil Cord With Plug End...

Page 51: ...November2006 Part No 833002 Rev A AL4000LightTower 51 Parts Catalog Section...

Page 56: ...November2006 56 AL4000LightTower Part No 833002 Rev A AXLE ASSEMBLY...

Page 58: ...November2006 58 AL4000LightTower Part No 833002 Rev A CABINET ASSEMBLY...

Page 60: ...November2006 60 AL4000LightTower Part No 833002 Rev A CABINET ASSEMBLY TOP DOORS...

Page 70: ...November2006 70 AL4000LightTower Part No 833002 Rev A TOWER BASE ASSEMBLY...

Page 72: ...November2006 72 AL4000LightTower Part No 833002 Rev A WINCH LOCK ASSEMBLY...

Page 78: ...November2006 78 AL4000LightTower Part No 833002 Rev A ELECTRICAL CONTROL BOX ASSEMBLY...

Page 80: ...November2006 80 AL4000LightTower Part No 833002 Rev A MH HPS LIGHT FIXTURE ASSEMBLY...