MAINTENANCE

285 MM191 (12---89)

3-26

TO CHANGE AN LPG FUEL TANK

1. Park the machine in a designated safe area.

WARNING: Fuel vapor is present when

servicing fuel system. Fire or explosion can

result. Keep flames and sparks away.

2. Close the tank service valve.

3. Operate the engine until it stops from lack of

fuel, then set the machine parking brake.

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, set parking brake,

and turn off machine.

4. Put on gloves and remove the quick-disconnect

tank coupling.

WARNING: LPG fuel is very cold.

Frostbite can result. Wear gloves when

connecting or disconnecting LPG hoses.

5. Inspect the LPG fuel lines for wear or damage.

6. Remove the empty LPG fuel tank from the

machine.

7. Check the tank for damage or wear.

8. Store the tank in a designated safe area.

9. Select a filled LPG fuel tank and inspect it for

damage or leaks.

NOTE: Make sure the LPG fuel tank matches the fuel

system (liquid tank with liquid system).

10. Carefully place the LPG tank in the machine so

that the tank centering pin enters the aligning

hole in the tank collar.

NOTE: If the pin cannot be engaged, make sure you

have the correct LPG fuel tank and then adjust the pin

locator in or out.

11. Fasten the tank hold-down clamp to lock the

tank in position.

12. Connect the LPG fuel line to the tank service

coupling. Make sure the service coupling is

clean and free of damage. Also make sure it

matches the machine service coupling.

13. Open the tank service valve slowly and check

for leaks. If an LPG leak is found, close the

service valve immediately and notify the

appropriate personnel.

14. If no leaks are found, the engine is ready to

start.

FUEL FILTER LOCK

The fuel filter lock filters the LPG fuel. It also stops

the flow of LPG fuel to the engine when the engine is

not operating or when the engine oil pressure is less

than 5 psi (35 kPa).

Replace the filter pack with the filter pack

replacement kit if diminished gas flow indicates the

filter is clogged. A drain plug is provided for purging

the filter bowl. Clean out the bowl when replacing the

filter pack.

VAPORIZER-REGULATOR

If any malfunction is noted, completely disassemble

the vaporizer-regulator. Clean all of the parts in

alcohol. Inspect all of the parts and replace where

needed. Carefully reassemble the vaporizer-regulator

with the seal repair kit. Check for proper operation.

CARBURETOR

If any malfunction is noted, completely disassemble

the carburetor. Clean all of the parts in alcohol.

Inspect all of the parts and replace when needed.

Carefully reassemble the carburetor with the seal

repair kit.

OIL PRESSURE SWITCH

The engine oil pressure switch requires no regular

maintenance. Never bypass the oil pressure switch

as this is a safety feature which prevents LPG fuel

from flowing when the engine is not operating

properly.

Summary of Contents for 285

Page 1: ...r 285 Sweeper Scrubber ...

Page 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Page 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Page 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Page 24: ...OPERATION 2 2 285 MM191 12 89 ...

Page 62: ...OPERATION 2 40 285 MM191 NIL ...

Page 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Page 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

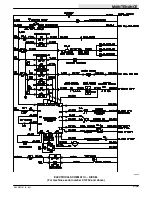

Page 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

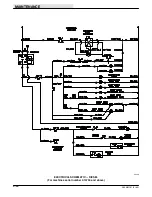

Page 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 134: ...APPENDIX 285 MM191 12 89 4 2 ...