OPERATION

2-12

285 MM191 (12---89)

ENGINE OIL PRESSURE INDICATOR

The engine oil pressure indicator

glows when

the engine oil pressure falls below 5 psi (35 kPa).

When the indicator glows, an audio alarm will sound

for 30 seconds and then the engine will stop. The

engine may be restarted --- the alarm may still sound.

If it does, you will have another 30 seconds before

the engine stops. Locate and correct the problem.

FUEL LEVEL GAUGE

The fuel level gauge

indicates how much fuel is

left in the fuel tank. It is present on gasoline and

diesel powered machines.

CLOGGED FILTER INDICATOR

The clogged filter indicator

glows when the

hopper dust filter is clogged.

To unclog the filter, shake it with the filter shaker

switch. If the filter shaker does not clean the filter

enough to turn the indicator off, clean the filter as

described in

HOPPER DUST FILTER

in the

MAINTENANCE

section.

FILTER SHAKER SWITCH

The filter shaker switch

operates the hopper

dust filter shaker.

To unclog the hopper dust filter, push the filter shaker

switch. The filter shaker motor will then operate for

30 seconds. If the filter shaker does not clean the

filter enough to keep the clogged indicator off, try it

again. Then if the filter shaker does not clean the

filter enough to keep the indicator off, clean the filter

as described in

HOPPER DUST FILTER

in the

MAINTENANCE

section.

MAIN BRUSH AND VACUUM FAN SWITCH

The main brush and vacuum fan switch

controls hydraulic fluid flow to the main brush

and vacuum fan motors. The switch also controls the

scrub attachment, and the snow broom motor (only)

when the machine is equipped with the snow broom

accessory.

To start main brush rotation and vacuum fan suction,

press the switch.

To stop main brush rotation and vacuum fan suction,

press the switch again.

ENGINE HOUR METER

The engine hour meter

records the number of

hours the machine has been operated. This

information is useful in determining when to service

the machine.

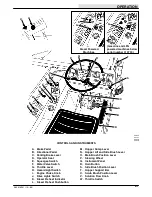

IGNITION AND START SWITCHES

The key-operated ignition switch

controls power

to all machine electrical components. The start

switch

operates the engine starter motor.

To start the engine, turn the key fully clockwise. Then

press and hold the start switch until the engine

starts.

NOTE: Do not operate the starter motor for more than

10 seconds at a time or after the engine has started.

Allow the starter to cool between starting attempts.

The starter may be damaged if it is operated

incorrectly.

To stop the engine, turn the key counter-clockwise.

FOR SAFETY: Before starting machine make sure

all safety devices are in place and operate

properly.

SIDE BRUSH POSITION LEVER

The side position lever controls the position of the

side brush.

To lower the side brush, pull the lever back and to

the left into the

(Side Brush Down) position. To

raise the side brush, pull the level back and to the

right into the

(Side Brush Up) position.

NOTE: Always raise the side brush when the machine

is not being operated for a period of time to prevent

the side brush from taking a set.

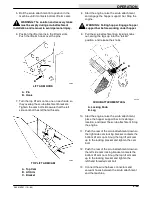

HOPPER SUPPORT BAR

The hopper support bar is located on the operator’s

side of the hopper. It holds the hopper in a “raised”

position to allow work to be done under the hopper.

Do not rely on the machine hydraulic system to keep

the hopper raised.

WARNING: Falling hopper. Engage hopper

support bar before working under hopper.

Summary of Contents for 285

Page 1: ...r 285 Sweeper Scrubber ...

Page 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Page 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Page 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Page 24: ...OPERATION 2 2 285 MM191 12 89 ...

Page 62: ...OPERATION 2 40 285 MM191 NIL ...

Page 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Page 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

Page 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 134: ...APPENDIX 285 MM191 12 89 4 2 ...