MAINTENANCE

3-25

285 MM191 (12---89)

FUEL TANKS

The LPG fuel tanks should be inspected for sharp

dents, gouges, leaks, and broken protecting rings

whenever the tanks are refilled. All tank valves must

be inspected for leaks using a soap solution. Valves

must also be checked for dirt, paint, or other debris

in the valve openings. The following specific checks

must also be made:

Filler Valve --- Check for proper functioning and the

presence of the handwheel. Valve must be closed

except during filling.

Vapor and Liquid Service Valves --- Check for proper

functioning and presence of the handwheel. The

valve must be closed except when in service.

Tank Service Valve Coupling --- Check for proper

functioning, thread condition, and damaged or

missing washers or o-rings.

Safety Relief Valve --- Check for damage. Check for

the presence of the relief valve elbow and the proper

direction of the elbow. If the rain cap is missing,

check for foreign matter and replace cap. Do not

tamper with the relief valve setting.

Liquid Level Gauge --- Check operation against the

maximum filling point as determined by weight.

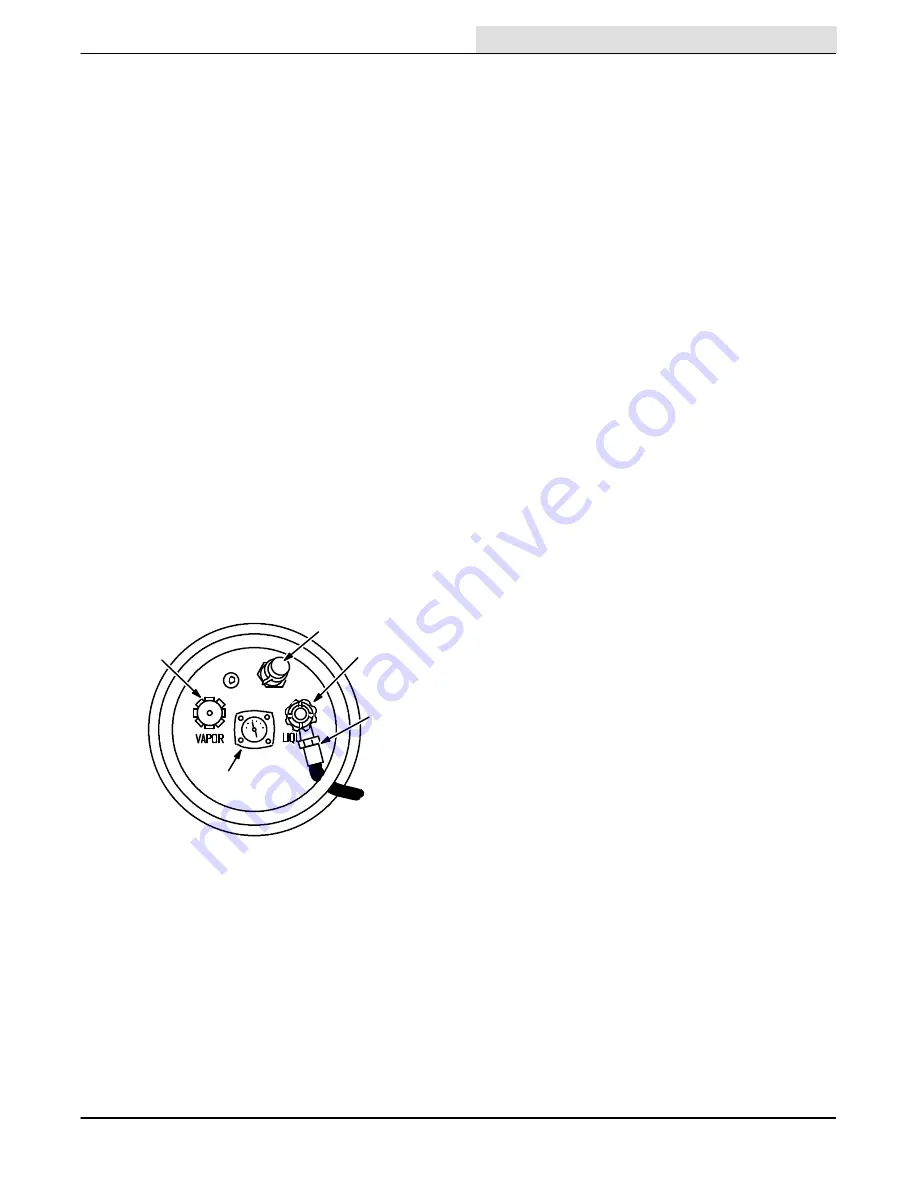

A

B

C

D

E

03485

TYPICAL LPG LIQUID WITHDRAWAL FUEL TANK

A. Filler Valve

B. Safety Relief Valve

C. Liquid Service Valve

D. Service Valve Coupling

E. Liquid Level Gauge

An LPG fuel tank with any of the stated defects must

be removed from service and be repaired or

destroyed accordingly.

If an LPG fuel tank is damaged or leaking, it should

be removed to a designated safe area, and the

proper personnel should be notified. Do not attempt

to make repairs to the tank, regardless of condition.

Repairs or disposal must only be made by qualified

personnel.

The care an LPG fuel tank receives has a direct

bearing on how long that tank can be used safely.

LPG fuel tanks must not be dropped or dragged

across any surface. To move LPG fuel tanks, use a

hand truck or roll the tank on its foot ring while it is

being held in a position slightly off vertical.

Whether the storage is inside or outside, fuel tanks

should not be stored in the vicinity of combustible

materials or high temperature sources such as ovens

and furnaces, since the heat may raise the pressure

of the fuel to a point where the safety relief valves

would function. Care should be taken to insure that

the tanks are stored in such a manner that if the

safety relief valves do function, they will relieve vapor,

rather than liquid.

Valves on empty tanks must be closed during

storage and transportation.

Similar precautions should be taken in storing

machines fitted with LPG fuel tanks. They may be

stored or serviced inside buildings, provided there

are no leaks in the fuel system and the tanks are not

overfilled. While machines are being repaired inside

a building, the shut---off valve on the tank must be

closed, except when the engine must be operated.

The tank changing operation presents an

opportunity for the machine operator to carefully

observe the tank, fittings, and the fuel lines and

fittings for his own satisfaction. If abnormal wear is

detected, the operator should report it to the

appropriate personnel for action.

Summary of Contents for 285

Page 1: ...r 285 Sweeper Scrubber ...

Page 6: ...ABOUT THIS MANUAL 285 MM191 12 89 d ...

Page 18: ...SPECIFICATIONS 285 MM191 12 89 1 2 ...

Page 22: ...SPECIFICATIONS 285 MM191 12 89 1 6 ...

Page 24: ...OPERATION 2 2 285 MM191 12 89 ...

Page 62: ...OPERATION 2 40 285 MM191 NIL ...

Page 76: ...MAINTENANCE 285 MM191 12 89 3 14 04644 HYDRAULIC SCHEMATIC LOW DUMP MODEL ...

Page 77: ...MAINTENANCE 3 15 285 MM191 12 89 04645 HYDRAULIC SCHEMATIC MULTI LEVEL DUMP MODEL ...

Page 103: ...MAINTENANCE 3 41 285 MM191 6 90 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 104: ...MAINTENANCE 285 MM191 6 90 3 42 06187 ELECTRICAL SCHEMATIC AUTO SHAKER RFS ...

Page 134: ...APPENDIX 285 MM191 12 89 4 2 ...