- 4 -

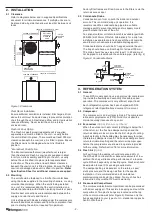

4.7 Unit Controller (UC8)

The unit’s UC8 controller receives requests such as ‘Unit

On/Off’, ‘Start compressors’, ‘Activate HEAT (Reverse

Cycle)’ and transfer the requests to the outputs after

enforcing safety timers.

Figure 4. UC8 Controller

The Unit Controller provides several system protection

functions. These are covered in Appendix I (p.9).

For additional information, refer to the UC8 Controller label

on the unit or www.temperzone.biz for operation & fault

diagnostics information; model search ‘UC8’.

References available:

UC8 Operation Manual : Air-to-Air Units

UC8 Fault & Display Messages (as per unit label)

UC8 Quick Reference and Operation Fault Diagnosis

UC8 Troubleshooting Guide

UC8 Modbus Communications

UC8 BACnet Communications

UC8 Master-Slave Connection

4.8 Control using switched and 0-10V signals

An external controller that provides 24V AC switched

signals or has a set of voltage-free relay contacts should

be connected as per the diagram below. UC8 inputs ‘VF’

and ‘VC’ will accept a 0-10V capacity control signals. If no

capacity control signal is available then link UC8 terminals

‘VF’ and ‘5’ and ‘VC’ and ‘12’.

BMS / external controller

Capacity

UC8

0-10V 0V

HIGH

MEDIUM

LOW

COMP2

COMP1

HEA

T

HI ME LO C1

CP HT C2

12 VC 0V

24V AC or 12V DC

24V AC COM or 0V

5 VF 0V

0-10V 0V

Comp.

Fan

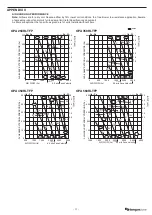

4.9 Control via Modbus RTU communications

OPA Econex units can be fully monitored and controlled via

Modbus RTU serial communications.

The following is typical for most installations:

• Set DIP switches 11 and 12 to OFF on all UC8 controllers.

• Connect BMS terminal A / TX+ to terminal A1 on the

UC8 controller via terminal block shown.

• Connect BMS terminal B / TX- to terminal B1 on the

UC8 controller via terminal block shown.

Multiple OPA units can be daisy-chained together.

For detailed information about monitoring and control

via Modbus RTU refer to document ‘UC8 Modbus

communications’, available at www.temperzone.biz (model

search ‘UC8’) or .com website.

4.10 Setting the UC8 Modbus device address

To view or change the Modbus device address of a UC8

follow these steps:

• Power up the unit but leave the compressors off.

• Hold down the SW3 pushbutton on the UC8 circuit board

until the display shows:

‘0’ [release] ‘1’ short press to ‘2,’ [long press] A,

[long press]

• The display will show the current Modbus device address.

The factory default address is ‘44’. [Short press] the button

to select higher numbers, for example press once to

change the address to 45, press twice for address 46 and

so forth. [Long press] to save the chosen address. After

address 99 the number returns back to 1.

• The controller returns to the default state (– ●).

4.11 Economiser Option (Controls by Others)

The Economiser package that is factory fitted consists of

two opposed blade dampers, one for the fresh air and the

other for the return air and complete with individual damper

motors controllable from a 0 – 10V dc signal. The package

also includes a fresh air weathercowl supplied as a kitset

that must first be assembled, then fitted to the unitt –

usually before the unit is lifted into place.

The damper control will be factory wired such that the return

air damper will close proportionally as the fresh air damper

opens proportionally and vice versa. The fresh air damper’s

adjustable stop can be set such that it does not close

100%; many installations may require a minimum fresh air

introduction of 10 – 15% and the stop may be set on site to

facilitate this. Set the economiser Fresh Air Damper motor

‘stop’ to the equivalent negative static pressure as with

F/A damper closed. This is to ensure the air flow volume

remains constant and does not dramatically increase when

introducing fresh air. Failure to set the correct ‘stop’ position

could result in rain/moisture entrainment in the incoming

fresh air resulting in water deposited inside the unit.

As previously mentioned, a 0 – 10V dc control signal is

required to drive the dampers open and closed. This could

be from a BMS or a temperature/humidity controller.

LCD Display

Push button